Method for refining crude toluene diisocynate

A technology of crude toluene diisocyanate and refining method, which is applied in the field of refining crude toluene diisocyanate, and can solve the problems of high residue formation speed, increased cost of final product TDI, reactor clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

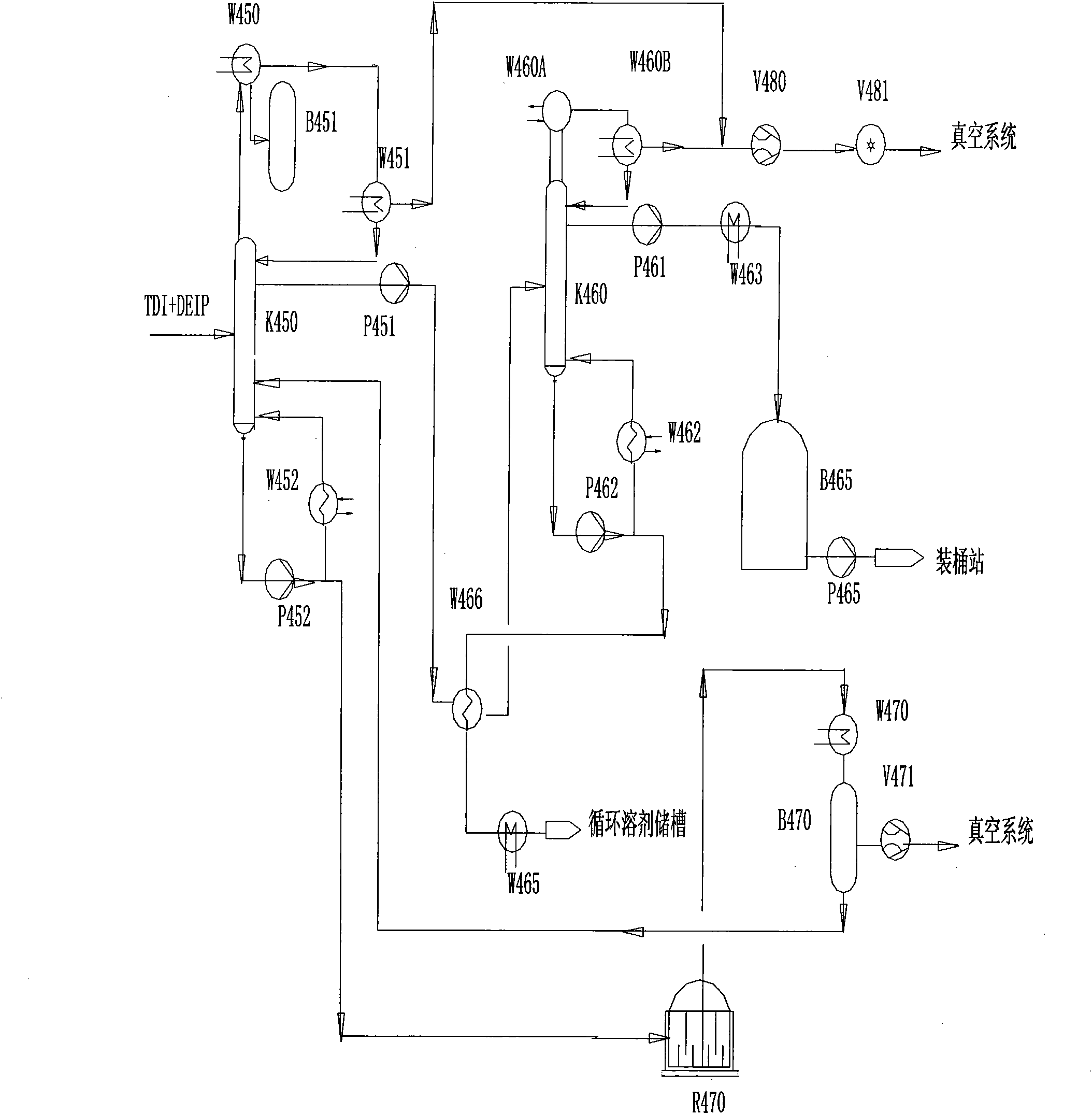

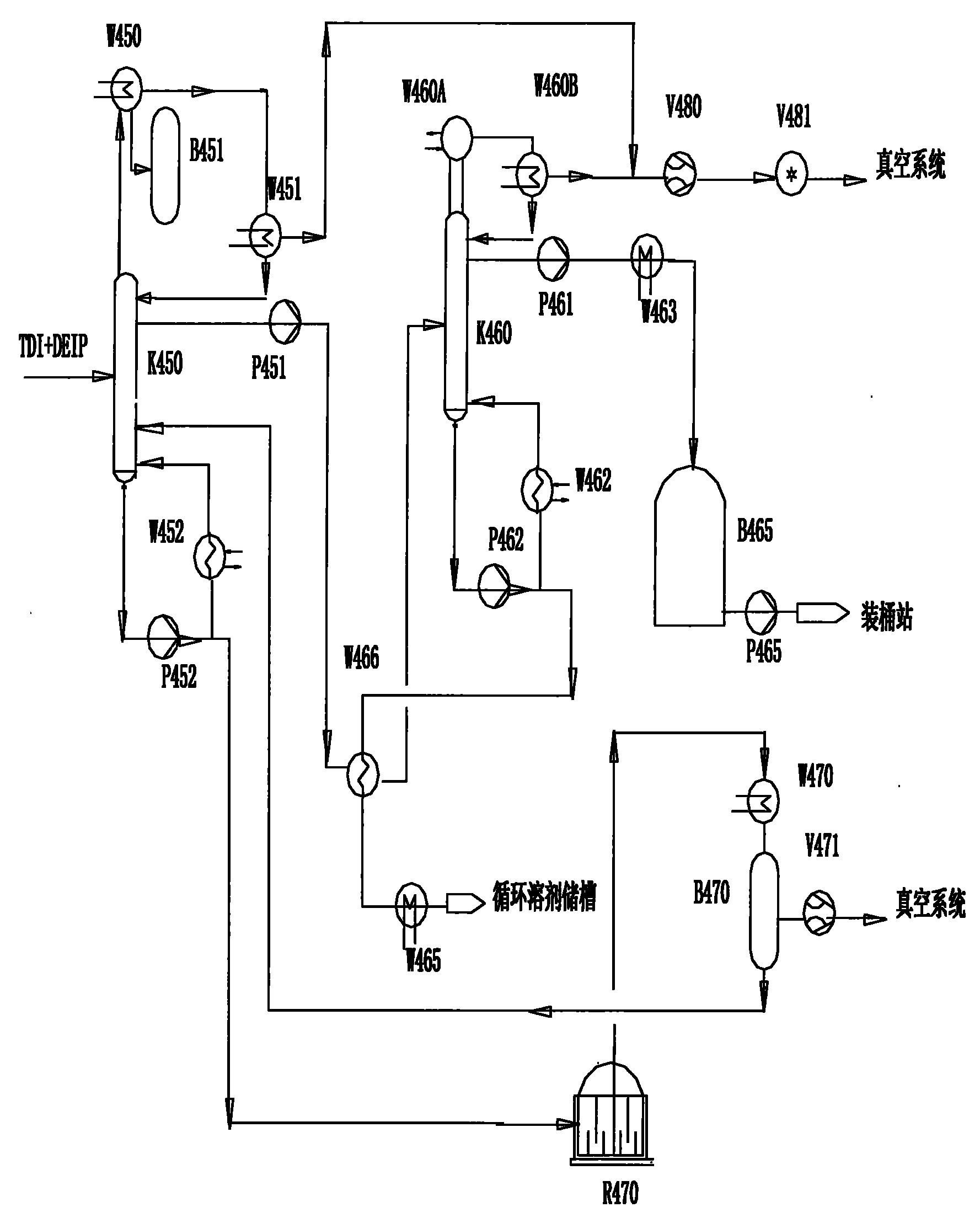

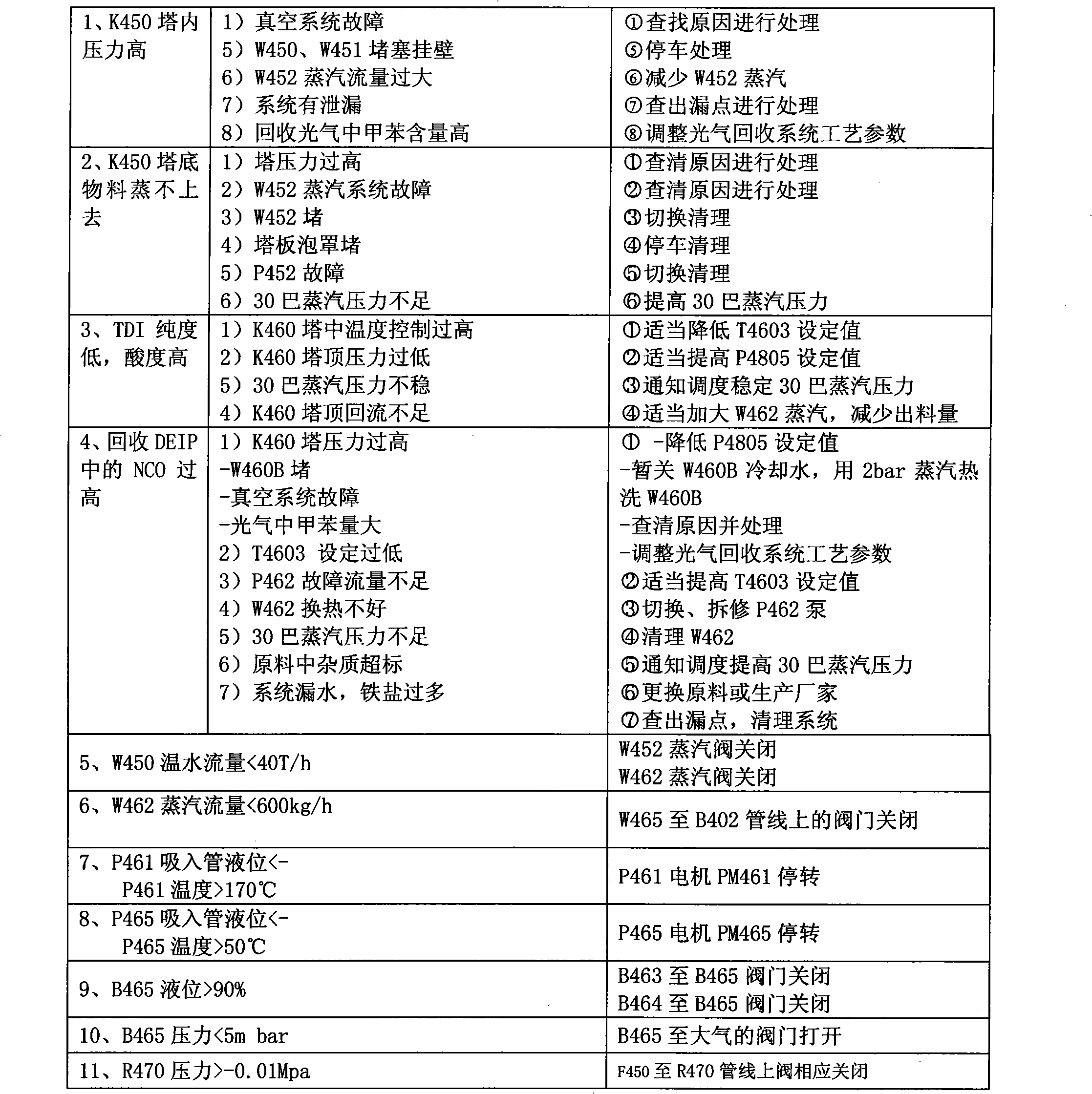

[0028] 经负压脱光气阶段后的TDI与DEIP混合物进入TDI残渣脱除塔K450,塔釜温度达到170℃,塔底压力1.56KPa,经釜液出料泵P452,釜液经再沸器W452加热后强制循环,返回TDI残渣脱除塔K450塔釜;部分进入残渣浓缩器R470,利用热油加热R470,减压状态下TDI与DEIP从R470上部被蒸出,经W470冷凝后,冷凝液收集在B470后返回到K450塔中部回收DEIP和TDI,不凝尾气经真空泵V471抽至单独真空系统;塔顶气体经冷凝器W450温水冷却后,冷凝液进入B451定期回收,未冷凝的气体进入W451,冷凝后冷凝液返回K450塔顶,不凝尾气经真空泵V480、V481抽至真空系统。TDI和DEIP物料从K450塔顶用泵P451侧线抽出后经换热器W466升温后,再进入TDI脱溶剂塔K460,塔釜温度达到210℃,塔底压力1.48KPa,DEIP经釜液出料泵P462,经再沸器W462加热后强制循环,返回TDI脱溶剂塔K460塔釜;经换热器W466与进料换热降温后,再经釜液冷却器W465冷却至85℃,回DEIP储槽循环使用;塔顶气体经冷凝器W460A冷凝后,冷凝液回流K460塔顶,未冷凝的气体进入冷凝器W460B冷凝,冷凝液返回K460塔顶,不凝尾气经真空泵V480、V481抽至真空系统;从K460塔顶用泵P461将TDI侧线抽出,经冷却器W463冷却后,经分析合格后,送至TDI成品罐B465,用泵P465抽出去装桶外销。

[0029] 实施例一反应器、塔工艺条件控制如下表:

[0030]

Embodiment 2

[0032]After the negative pressure dephosphorization stage, the TDI and DEIP mixture enters the TDI residue removal tower K450 by the metering pump at a rate of 11500kg / h. The temperature of the tower kettle reaches 160°C and the pressure at the bottom of the tower is 1.56KPa. After being heated by the reboiler W452, it is forced to circulate, and returns to the bottom of the TDI residue removal tower K450; the residue enters the residue concentrator R470 at a rate of 850kg / h, and heats R470 with hot oil. Under reduced pressure, TDI and DEIP are evaporated from the upper part of R470 , after being condensed by W470, the condensate is collected in B470 and then returned to the middle of K450 tower to recover DEIP and TDI. The non-condensable tail gas is pumped to a separate vacuum system by vacuum pump V471; after the tower top gas is cooled by warm water in condenser W450, the condensate enters B451 regularly Recycling, uncondensed gas enters W451, condensed liquid returns to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap