Oil tank and gas tank fire control cooling valve

A technology of cooling valve and gas tank, which is applied to tank trucks, valve details, valve devices, etc., can solve the problems of untimely cooling, blind watering, and difficulty in cooling, and achieve the effect of improving water flow and realizing interchangeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

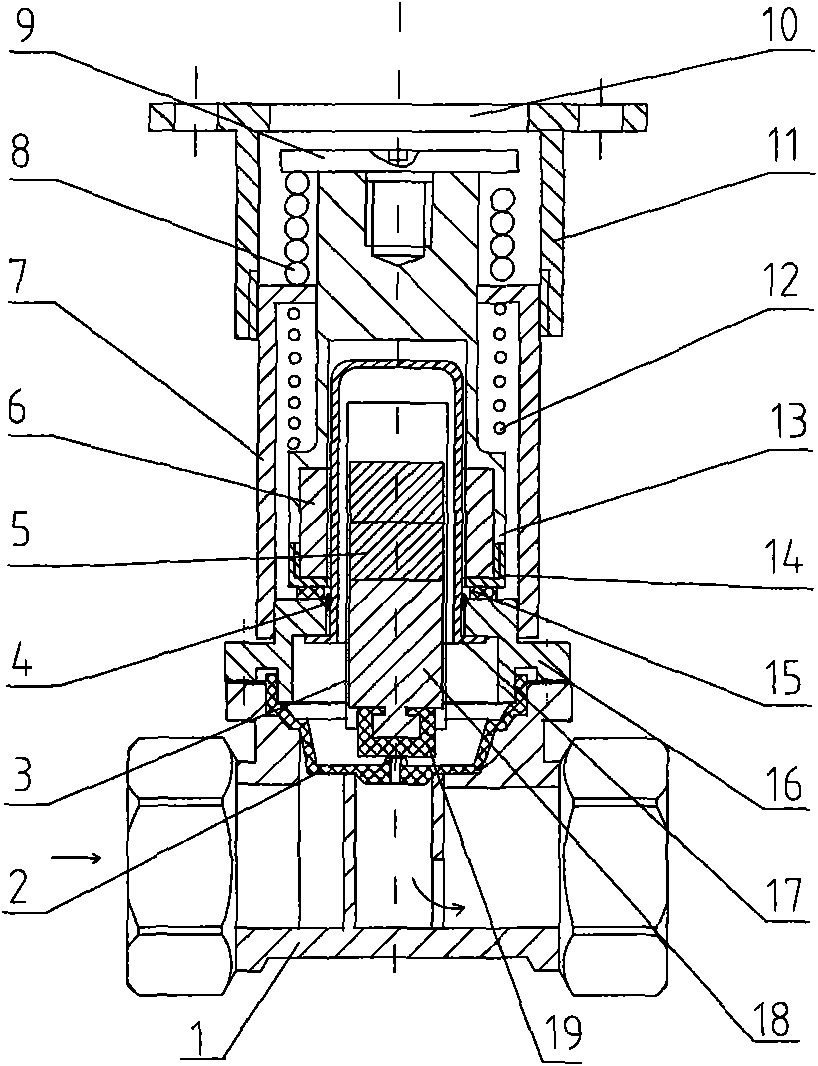

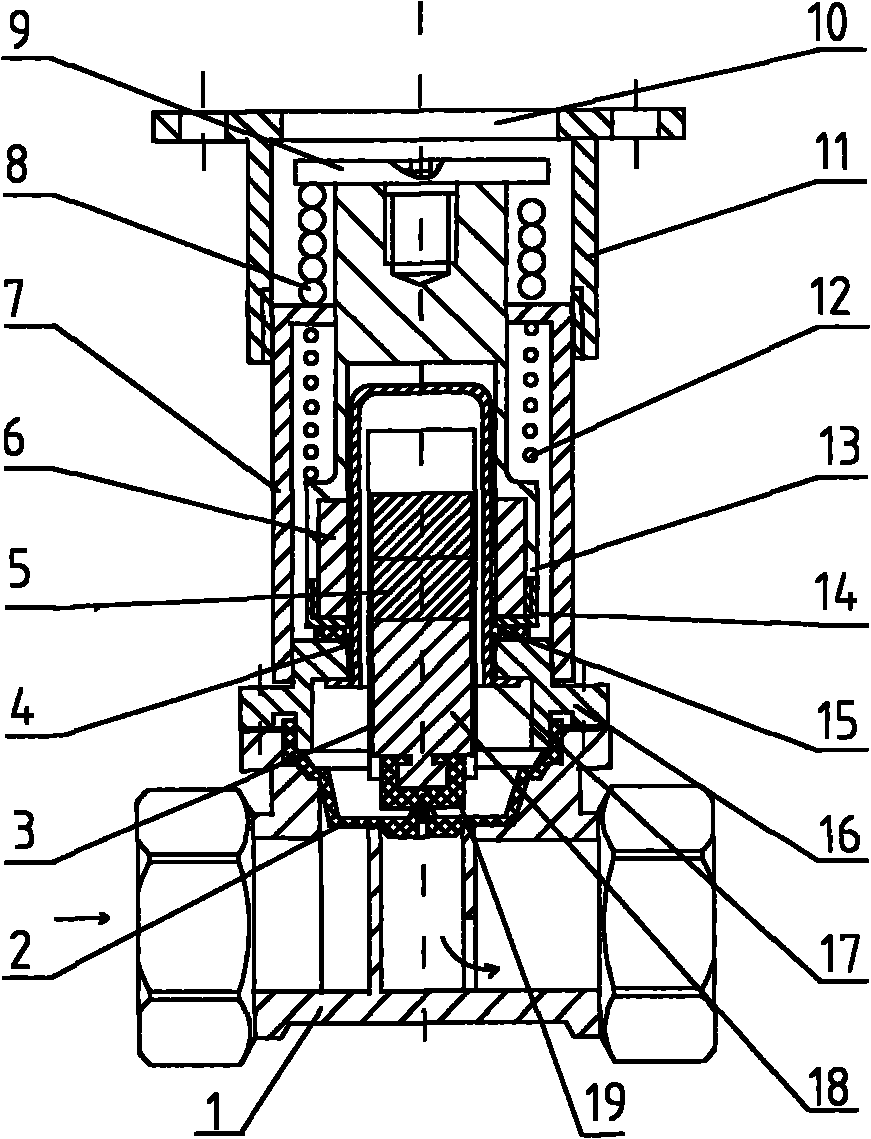

[0007] Accompanying drawing is the principle structural diagram of present embodiment. The invention consists of a valve body (1) and a temperature control head. There is a cylindrical water outlet in the valve body (1). A piston (2) is installed on the upper end of the water outlet. The pressure relief hole on the piston (2) cooperates with the piston rod (19) at the bottom of the valve core (3). (2) and a small through hole communicates with the water inlet of the valve body (1); the piston column (19) passes through the packing pad (17), and presses the magnetic column (5) into the valve core sleeve (16) to form the valve core (3); the upper end of the valve body (1) is connected together with the bonnet (16) by bolts, and the center hole in the bonnet (16) is equipped with a spool sleeve (17), and is welded (see welding point (4) )) is connected with the spool cover (17); the spool (3) is inserted in the spool cover (17), and can move up and down in the spool cover; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com