Flat-plate loop heat pipe

A loop heat pipe, flat-plate technology, applied in the field of flat-plate loop heat pipe, can solve the problem of small steam flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

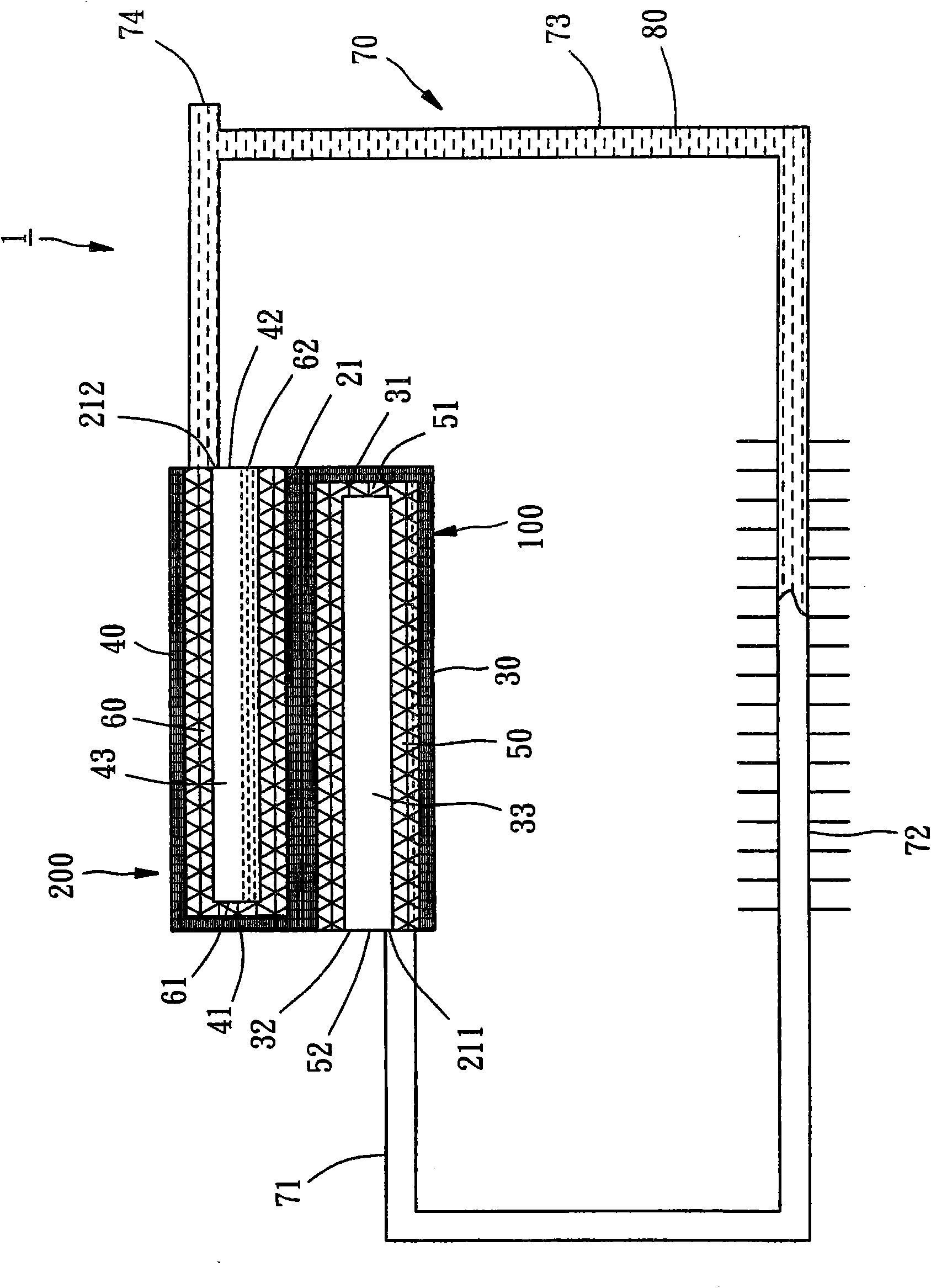

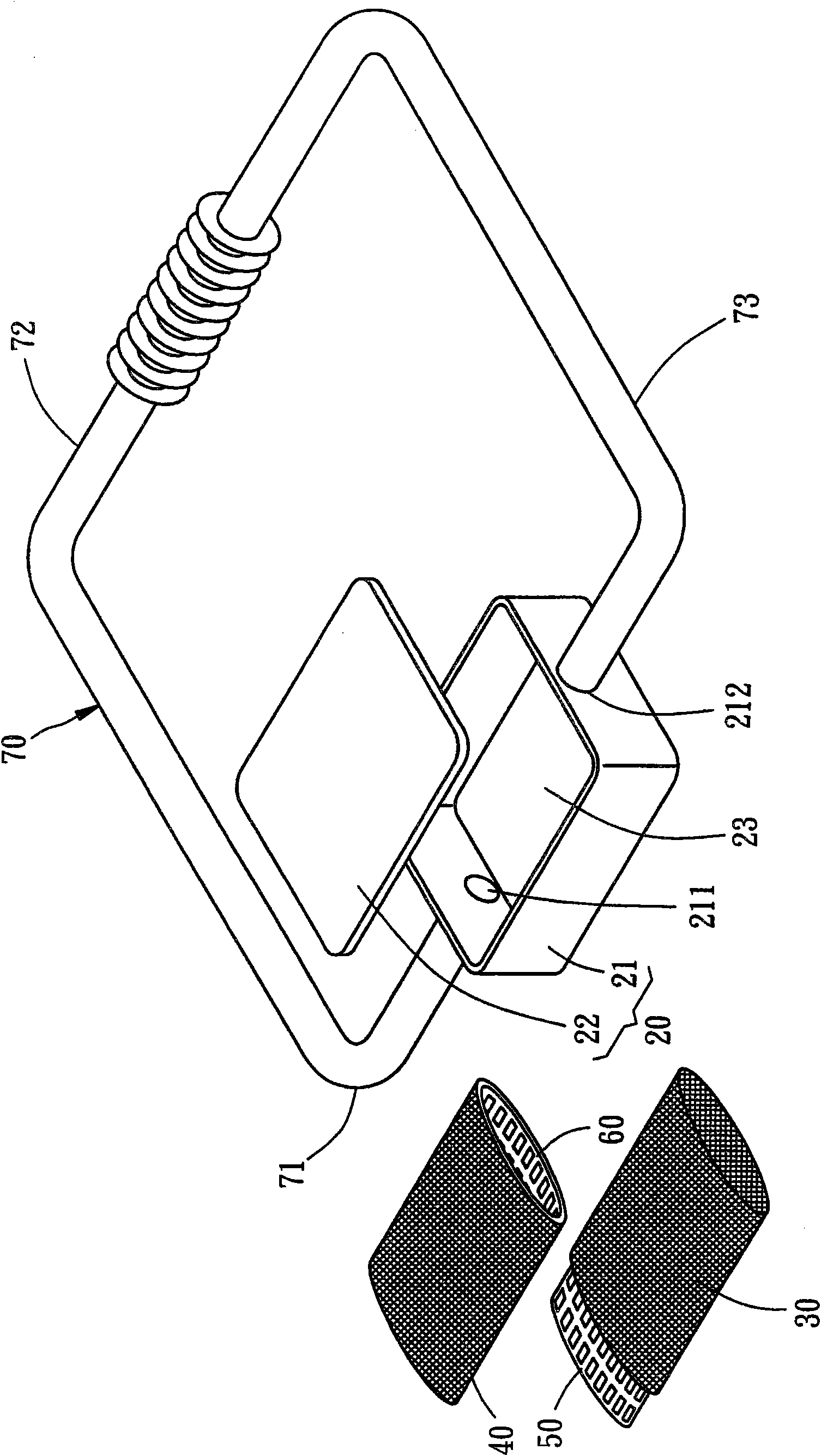

[0013] see Figure 1 to Figure 4 , the flat-plate loop heat pipe 1 of a preferred embodiment of the present invention includes: a container 20 , two liquid-absorbing cores 30 , 40 , two support frames 50 , 60 , a circulation pipe 70 and a working fluid 80 .

[0014] The container 20 includes a box body 21 and a cover body 22, which are combined to form a chamber 23; the box body 21 has two openings, which are respectively a steam outlet 211 and a liquid inlet 212; the steam outlet 211 The distance between the central position of the steam outlet 211 and the bottom of the box body 21 is smaller than the distance between the central position of the liquid inlet 212 and the bottom of the box body 21 , and the steam outlet 211 and the liquid inlet 212 are respectively located on the left and right sides of the box body 21 .

[0015] The liquid-absorbent cores 30, 40 have a capillary structure, and are respectively a first liquid-absorbent core 30 and a second liquid-absorbent core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com