Patents

Literature

50results about How to "Real-time heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

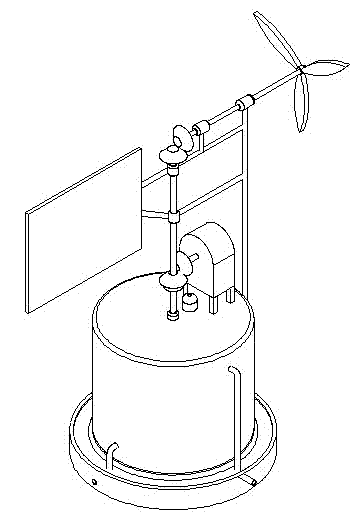

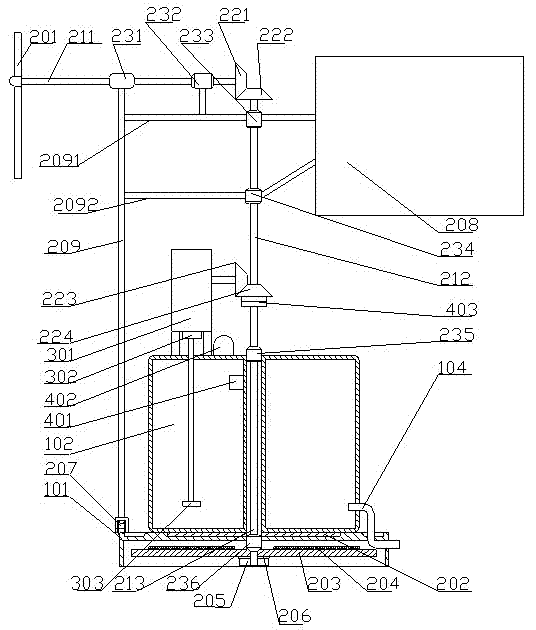

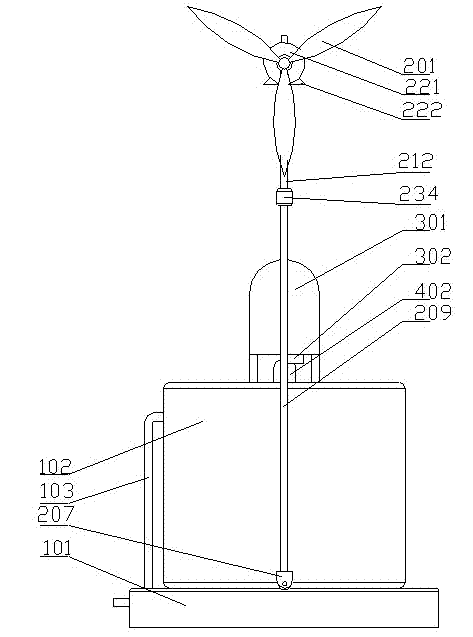

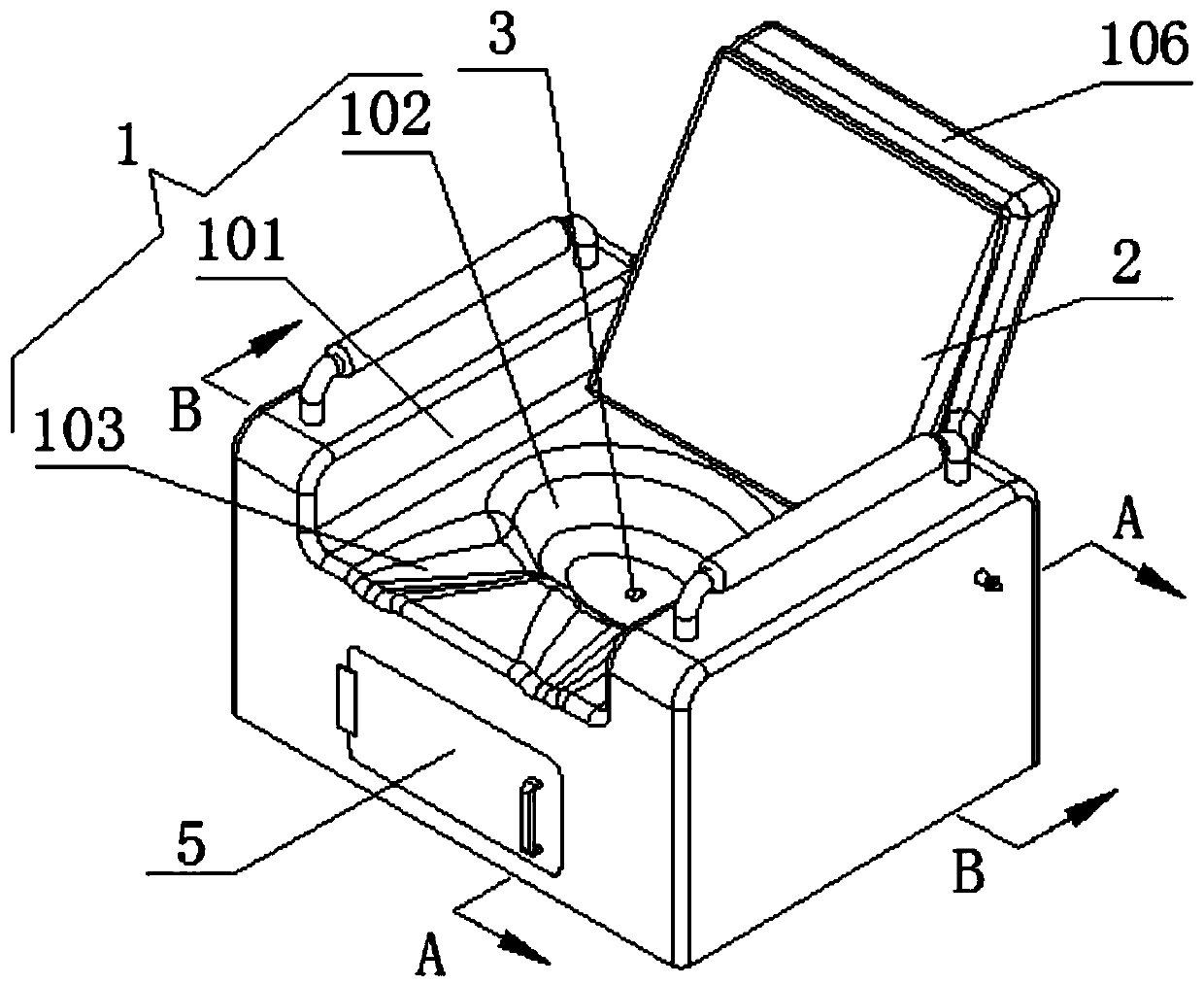

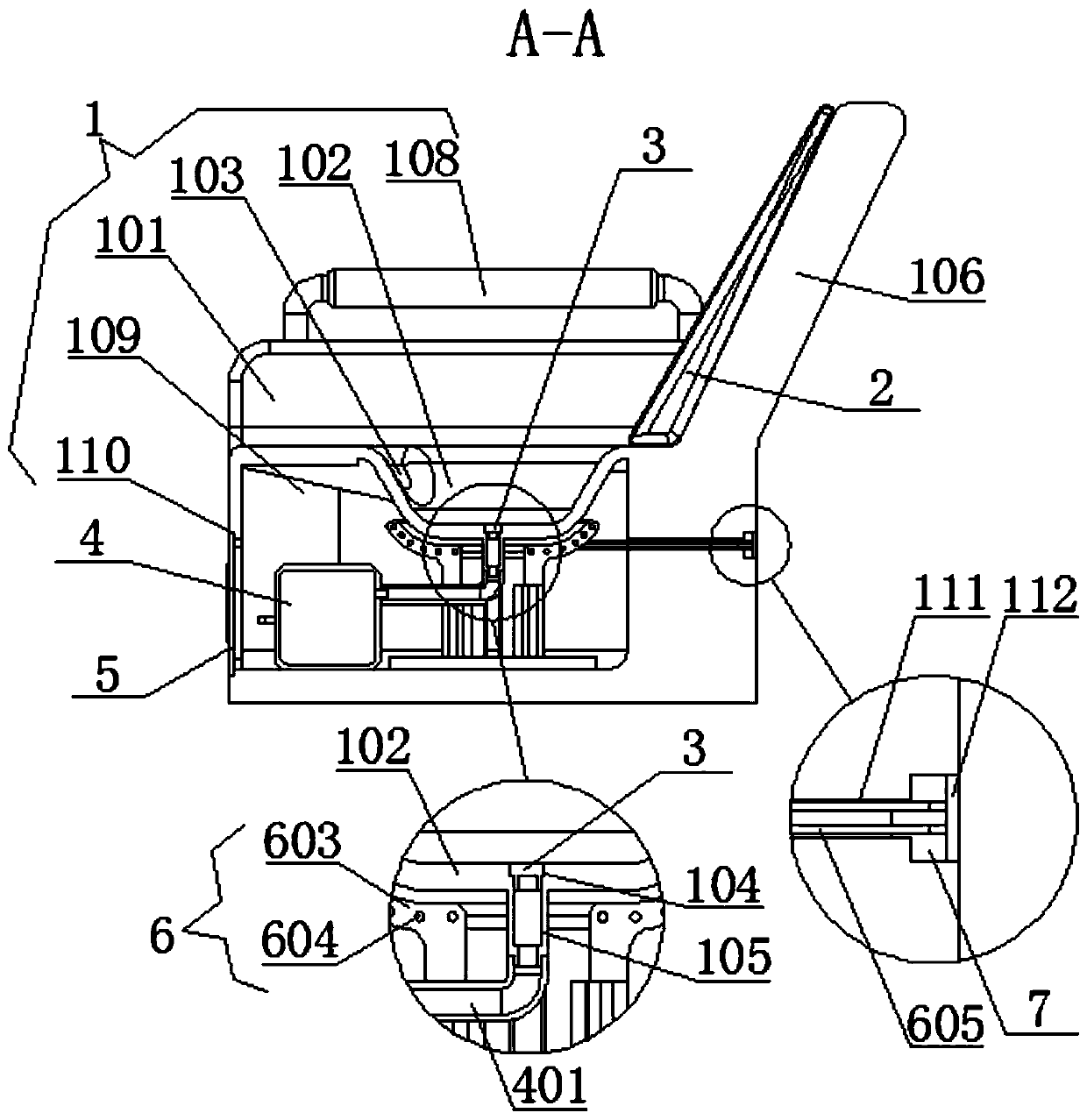

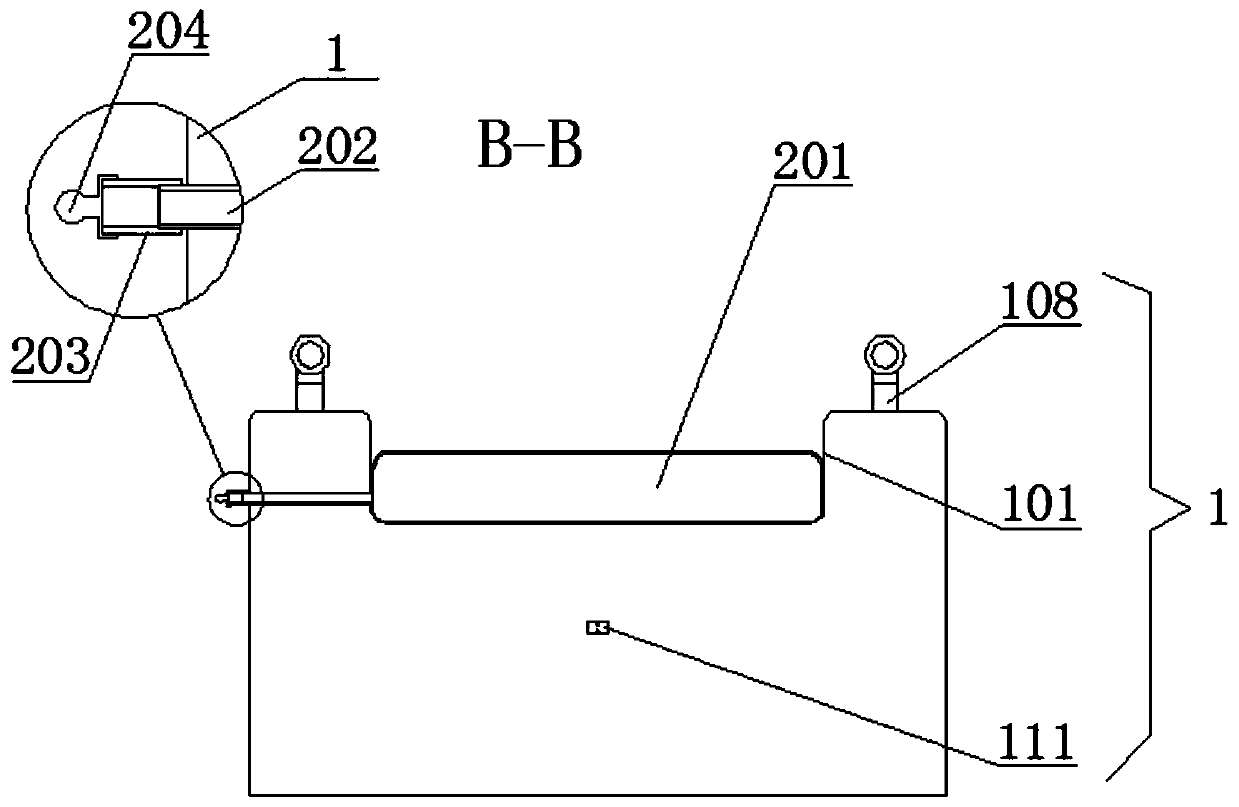

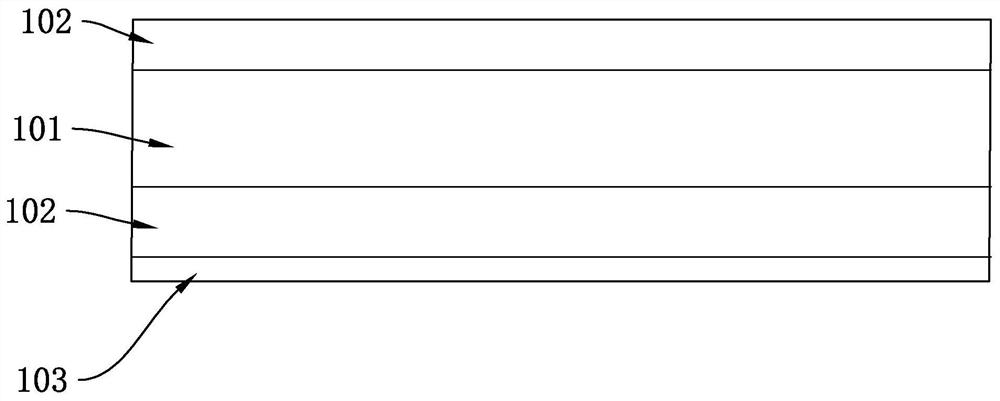

Novel wind-power water heater and control method thereof

ActiveCN103759409AIncrease profitReal time heatingWind motor controlFinal product manufactureThermal energyEngineering

The invention discloses a novel wind-power water heater and a control method thereof. The wind-power water heater comprises an incubator, a base, a device for converting wind energy to thermal energy, an electric heating device and an intelligent control system, wherein the incubator comprises a water inlet pipe and a water outlet pipe and the incubator is arranged on the base. A vortex heating principle is adopted in the novel wind-power water heater, so as to simplify intermediate procedures of wind power generation, reduce consumption of intermediate procedures and costs and be capable of achieving real-time heating, save energy and protect environment. The novel wind-power water heater is simple in principle, easy to manufacture, low in costs and good in performance.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

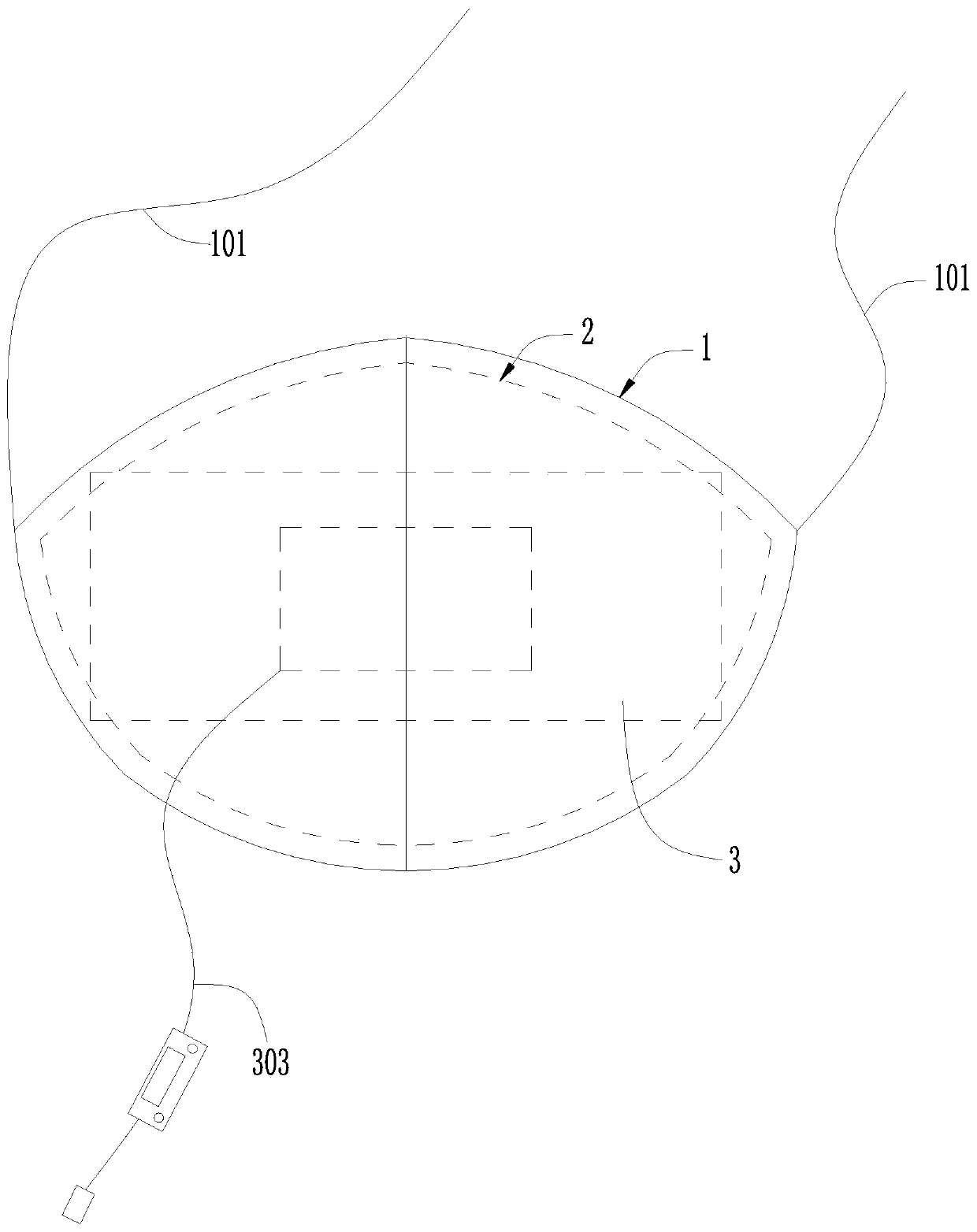

Rechargeable heating mask and processing method thereof

PendingCN111213933AAvoid destructionImprove adsorption capacityGarment special featuresHeatThermodynamicsEngineering

The invention discloses a rechargeable heating mask and a processing method thereof. The rechargeable heating mask comprises: a first mask layer; a second mask layer integrated on the inner side of the first mask layer; and a heating structure integrated between the first mask layer and the second mask layer. The heating structure is provided with a heating body and a heat transfer ventilation body fixed on the surface of the heating body, wherein a control circuit is arranged outside the heating body, and the heating body controls a heating temperature to be in a range of 20 DEG C to 60 DEG Cthrough the control circuit. According to the designed heating mask, the heating structure is integrated between the two mask layers, can realize continuous heating after supply of power, and is usedin cooperation with an existing medical mask to realize heating of the medical mask, guarantee a proper wearing temperature, prevent electrostatic charges in the medical mask from damage and improving the virus adsorption capacity of the medical mask. After the rechargeable heating mask is used, the mask is taken off, the temperature of the mask is adjusted to be about 56-60 DEG C, and heating iscontinued for 30 minutes, so viruses can be thoroughly killed, and the mask can be recycled.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

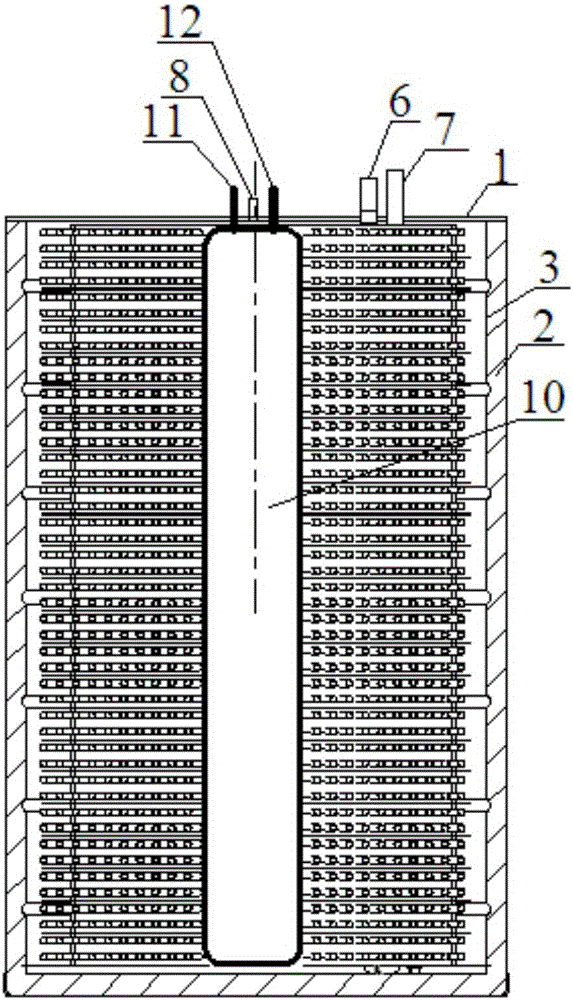

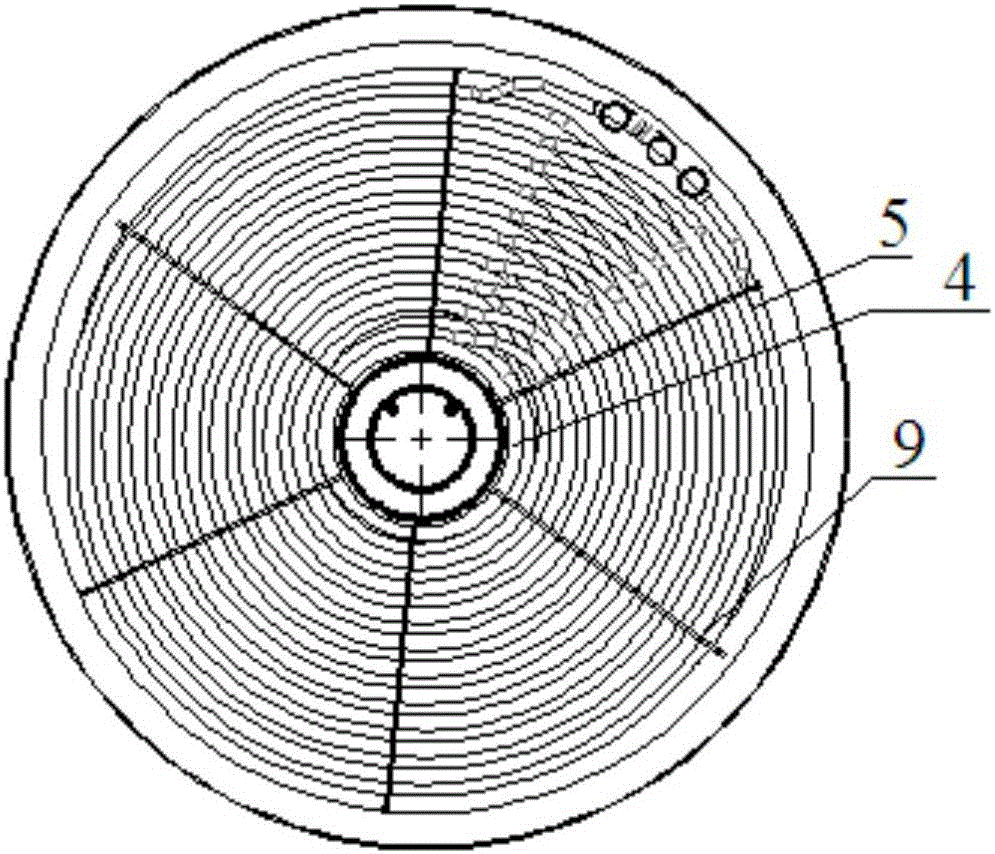

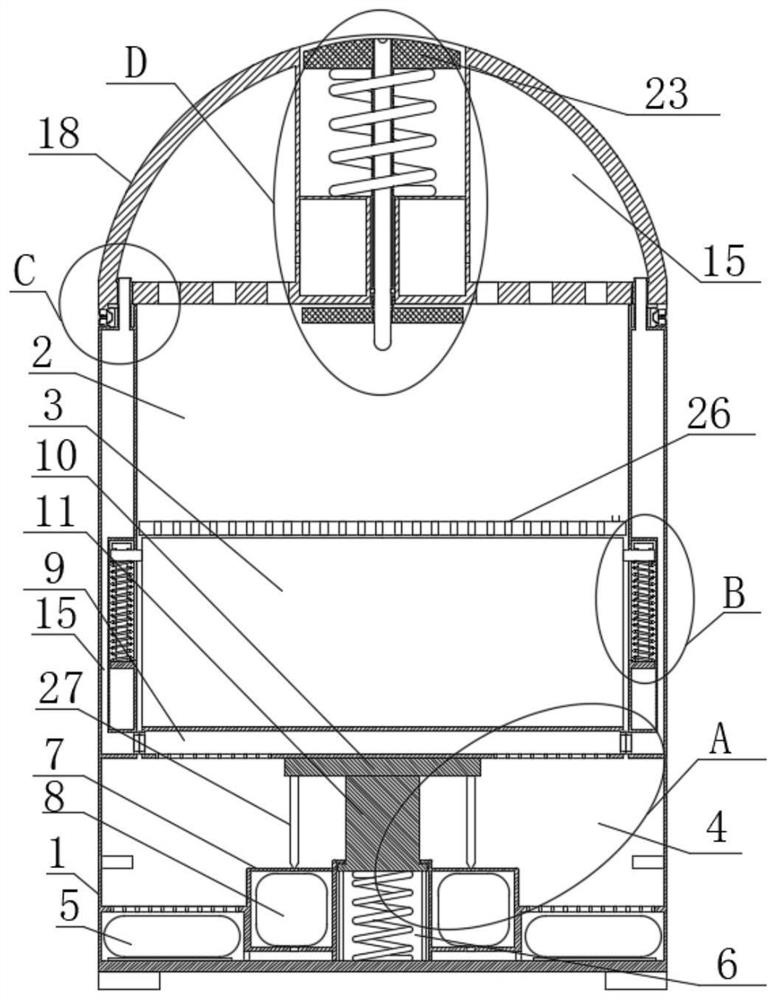

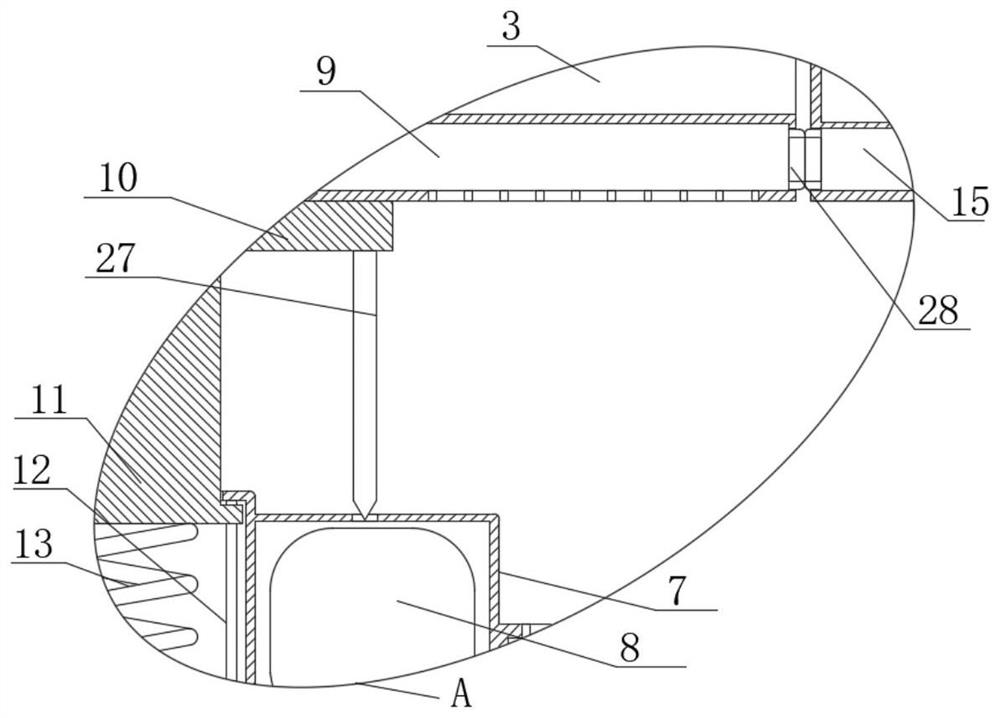

Phase-change type heat storage device with built-in water tank

ActiveCN104990438ASimple structureEasy to manufactureHeat storage plantsHeat exchange apparatusEngineeringWater requirement

The invention relates to a phase-change type heat storage device with a built-in water tank. The phase-change type heat storage device includes a shell, a liner arranged in the shell, a heat-insulating layer arranged between the liner and the shell; the liner is filled with a phase change material; a heat-exchange coil is buried in the phase change material; the inlet and outlet of the heat-exchange coil both extend out from the liner and are welded to and communicated with a water entering main pipeline and a water outgoing main pipeline respectively; the water entering main pipeline and the water outgoing main pipeline are connected with an external heat supply system; the built-in water tank is arranged in the liner; one end of the built-in water tank is provided with a cold water entering pipe; the other end of the built-in water tank is provided with a hot water outgoing pipe; and a space between the built-in water tank and the liner is filled with the phase change material. Compared with the prior art, the phase-change type heat storage device with the built-in water tank of the invention has the advantages of simple structure and high heat storage capacity, and can simultaneously meet heat and hot water demands. With the phase-change type heat storage device adopted, when the quantity of hot water is insufficient, the heat of the phase change material can be continuously provided for the inner tank; and the phase change process of the phase change material is stable, and therefore, the device can supply heat stably and continuously and can satisfy heating and hot water requirements of buildings.

Owner:PIONEER ENERGY JIANGSU

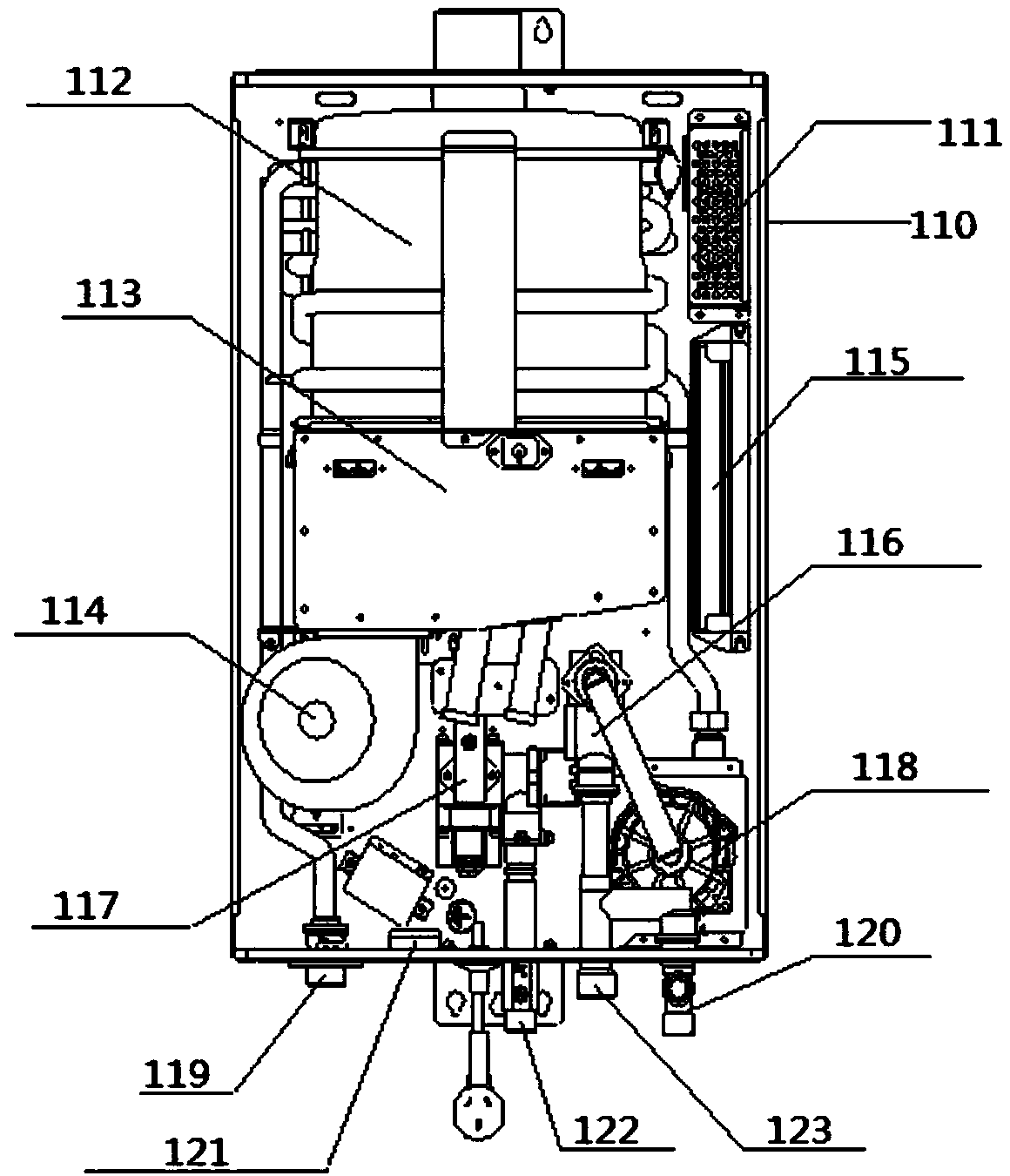

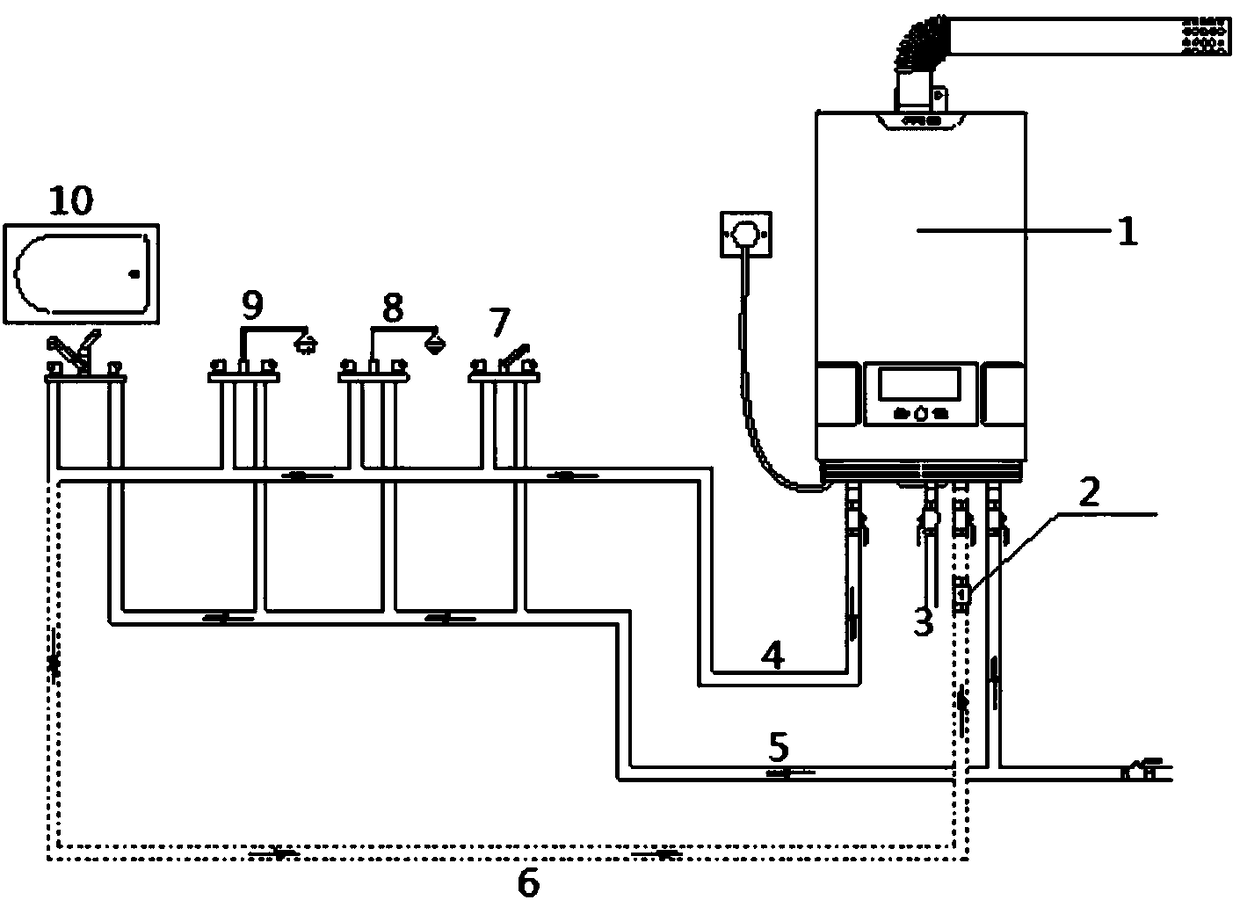

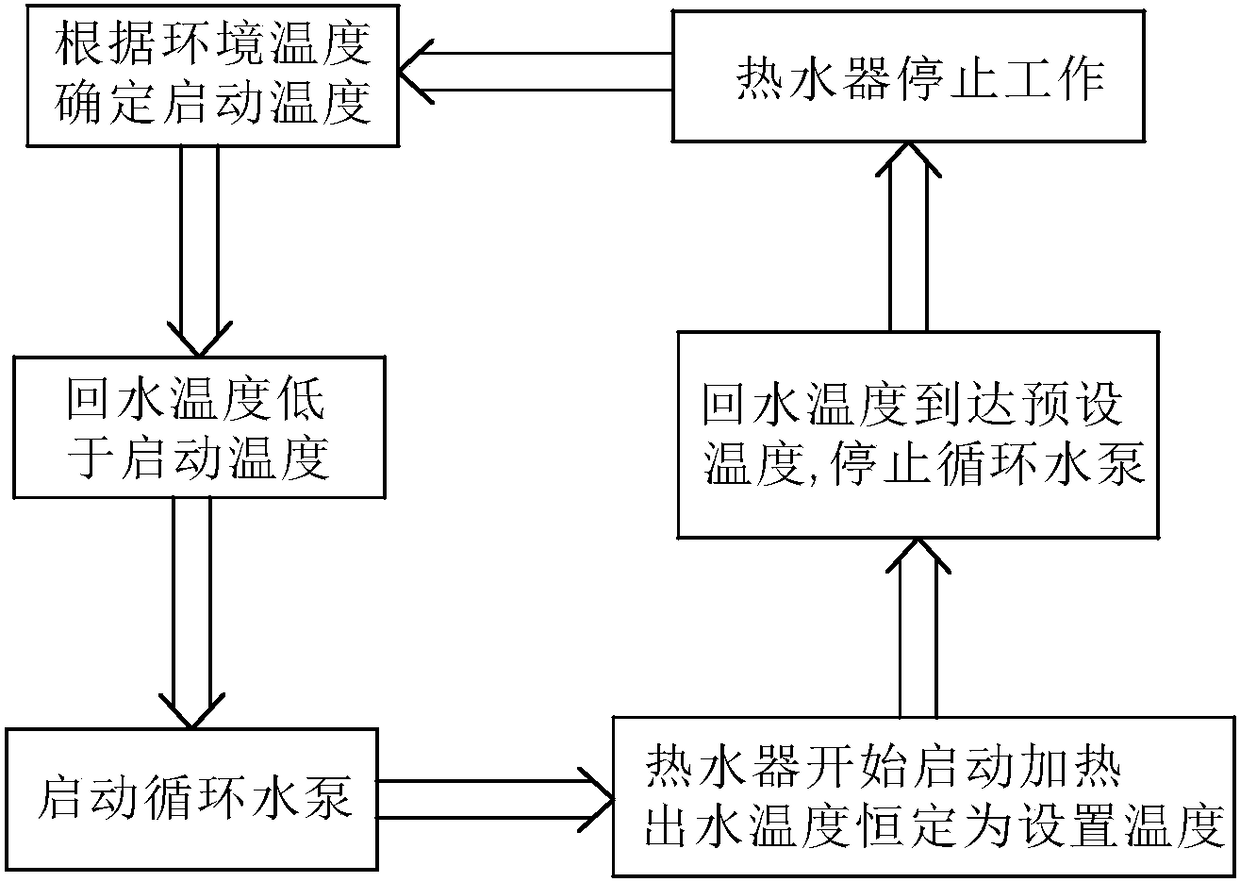

Energy-saving gas water heater with preheating function and heating system and method

The invention discloses an energy-saving gas water heater with the preheating function and a heating system and method. The water heater comprises a shell; a heat exchanger, an intelligent cabin combustion chamber, a direct-current brushless fan and a gas proportional valve are sequentially arranged in the shell from top to bottom; a hot water inlet, a gas inlet and a cold water inlet are formed in the bottom of the shell; a switching power supply for controlling the on-off states of the water heater is further arranged in the shell; an intelligent controller, a circulating water pump, an environment temperature sensor and a return water temperature sensor are further arranged in the shell; a return water inlet is further formed in the bottom of the shell; and the intelligent controller isin signal connection with the circulating water pump, the environment temperature sensor, the return water temperature sensor, the switching power supply, the gas proportional valve and the direct-current brushless fan. The energy-saving gas water heater and the heating system and method have the advantages of being short in heating time and energy-saving.

Owner:成都前锋电子有限责任公司

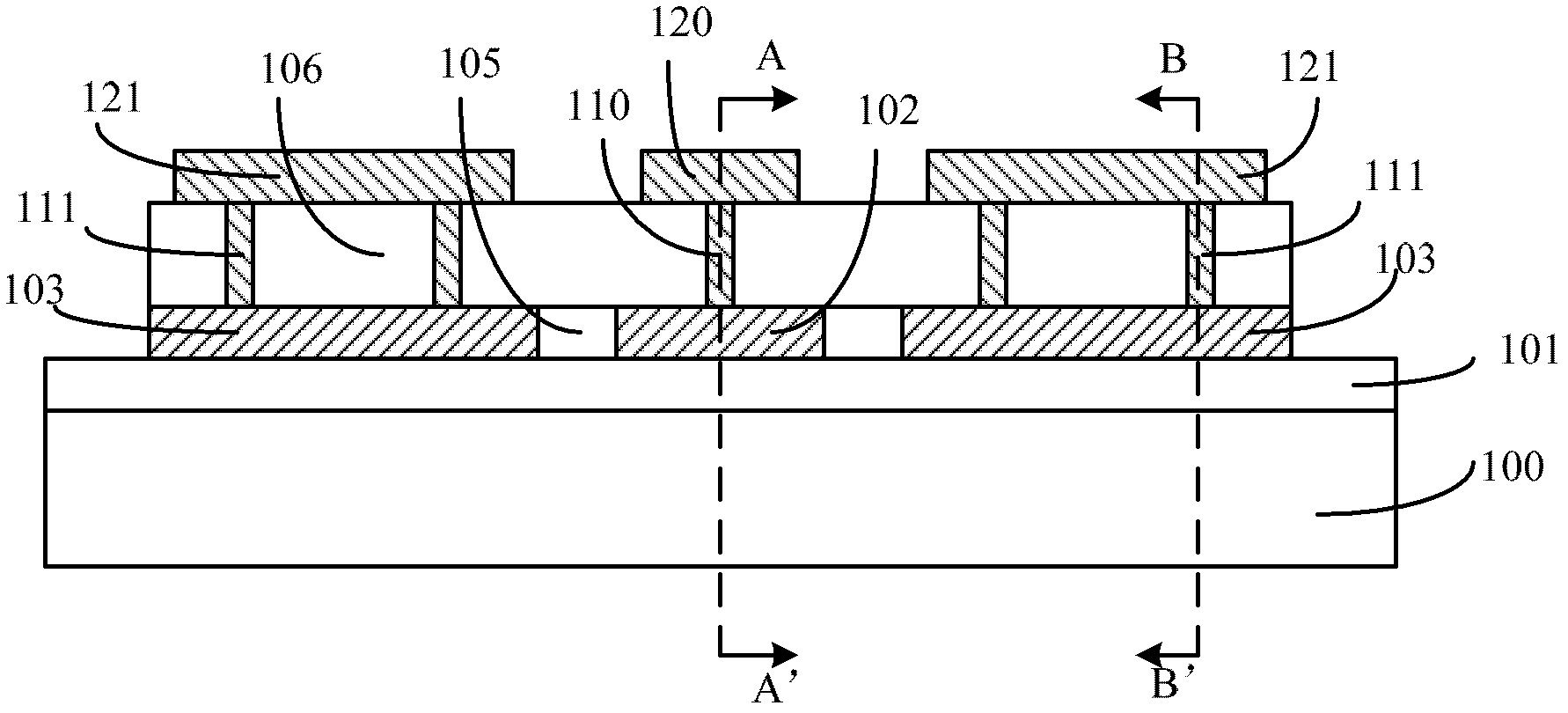

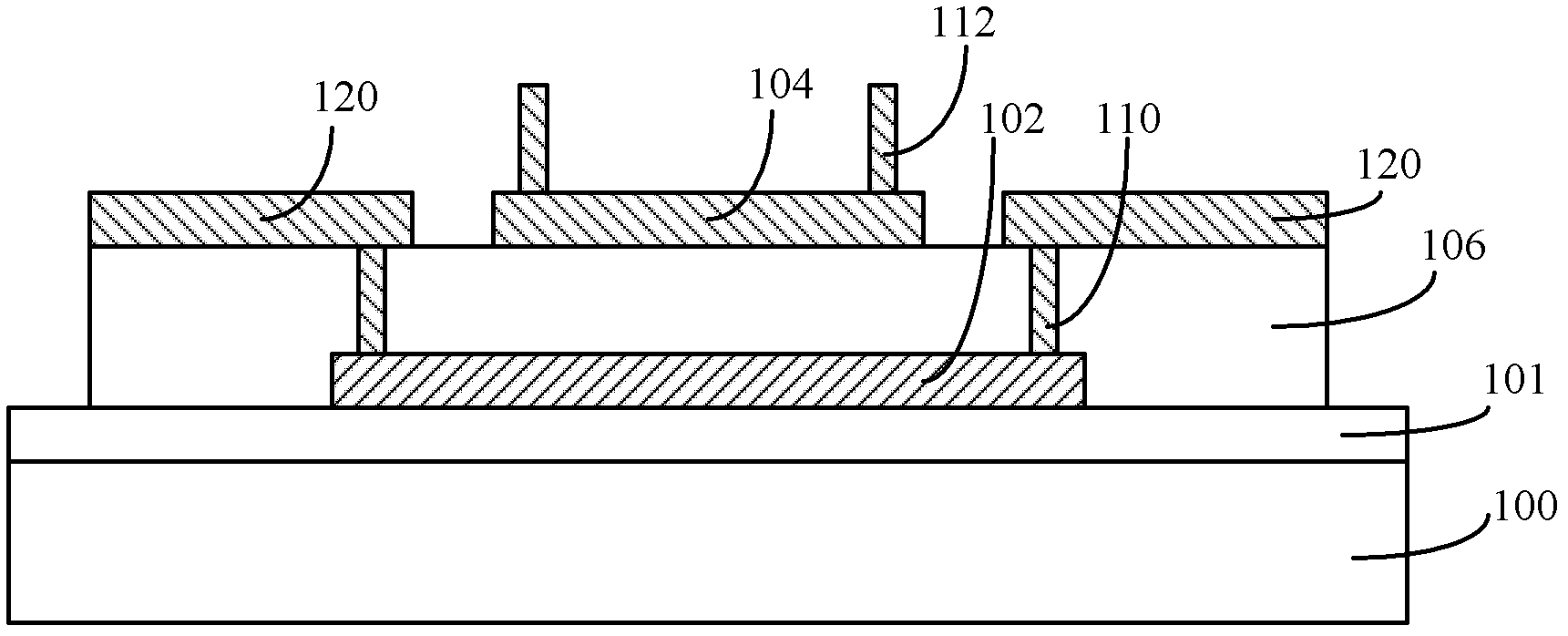

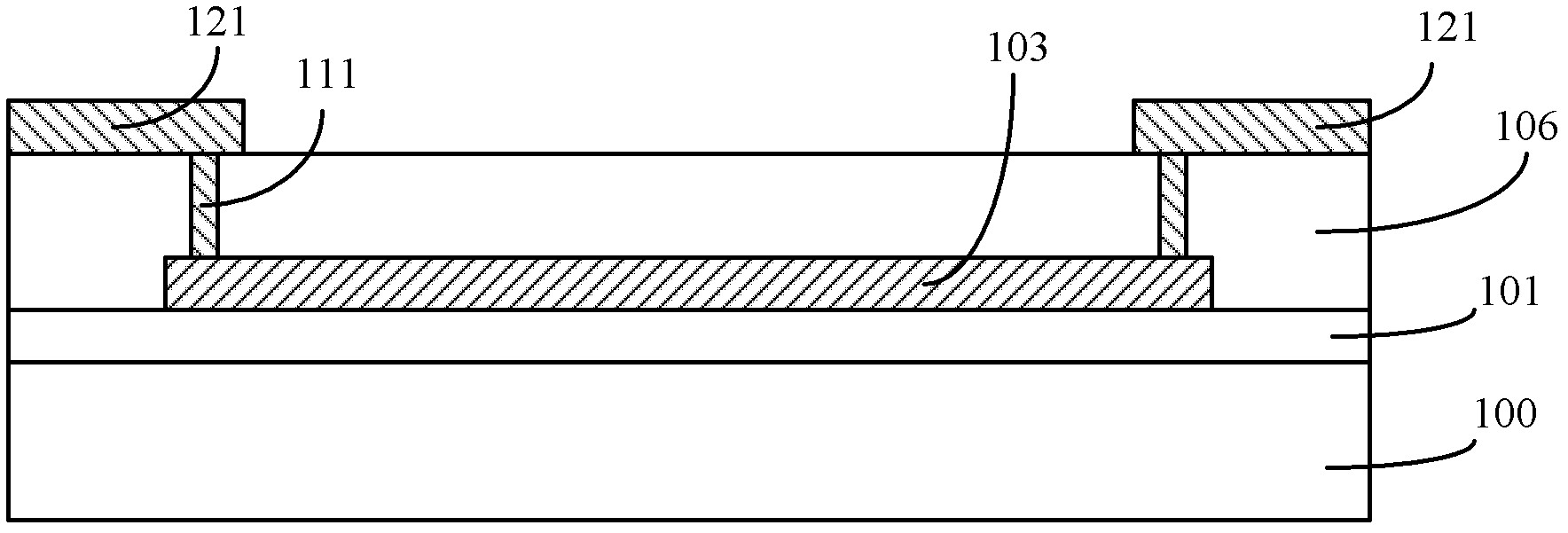

Detecting structure and detecting method for temperature coefficient of resistance (TCR)

ActiveCN102621468AReduce current densityHeating fastIndividual semiconductor device testingTemperature coefficientElectrically conductive

Disclosed are a detecting structure and a detecting method for a TCR, wherein the detecting structure of the TCR comprises a semiconductor substrate; a component to be detected made of polycrystalline silicon is placed on the surface of the semiconductor substrate, and the two ends of the component to be detected are respectively connected with first conductive plugs which are respectively connected with first metal interconnection lines; a heating layer made of polycrystalline silicon is arranged opposite to the component to be detected, and the two ends of the heating layer are respectively connected with second conductive plugs which are composed of at least two conductive plugs and connected with second metal interconnection lines respectively; a sensor is placed above the component to be detected, and the two ends of the sensor are respectively connected with third conductive plugs. The detecting structure of resistance temperature coefficients has the advantage of being capable of increasing the heating speed and the temperature measuring speed for the component to be detected, and further increasing the speed for detecting resistance temperature coefficients.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

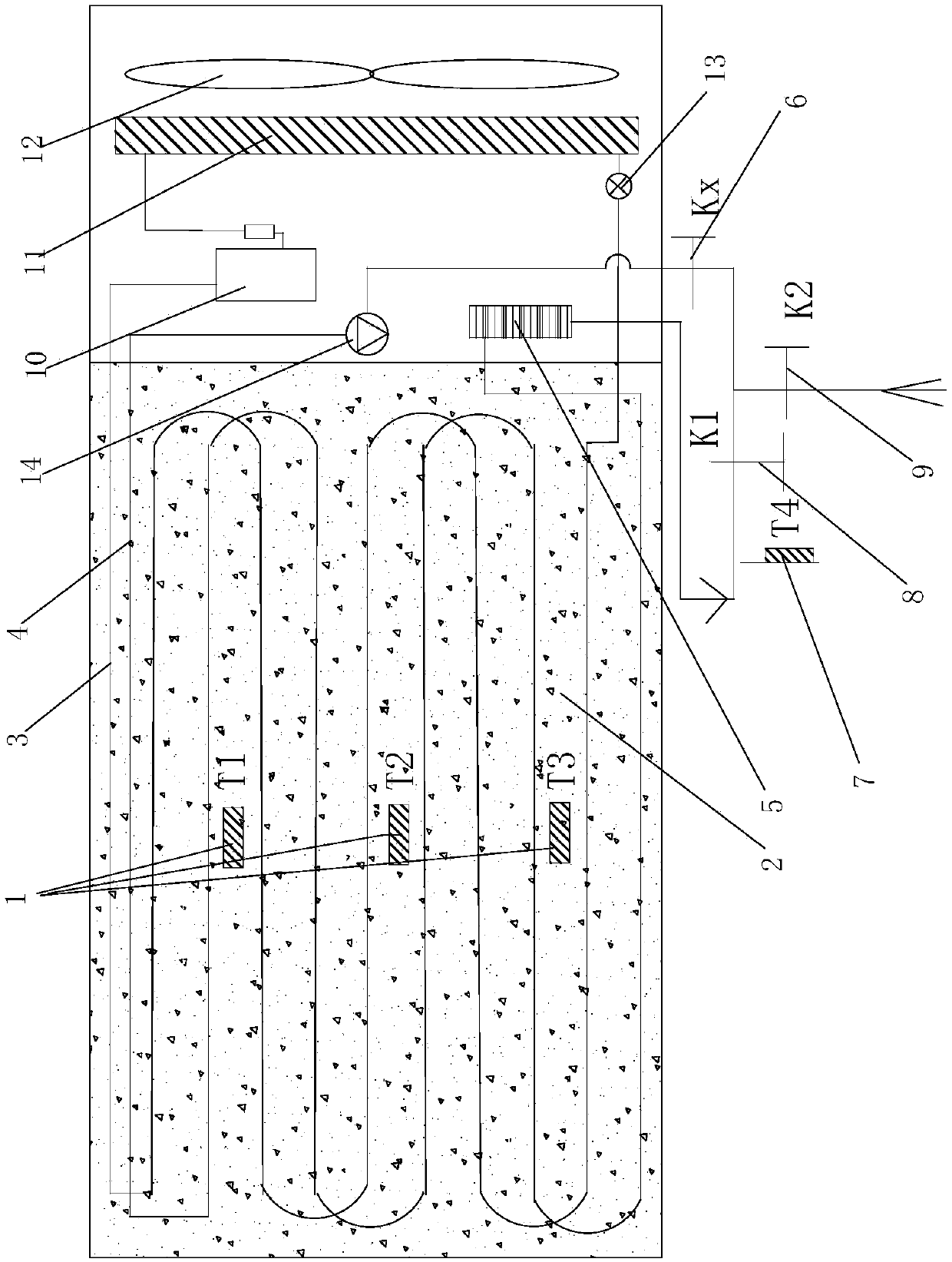

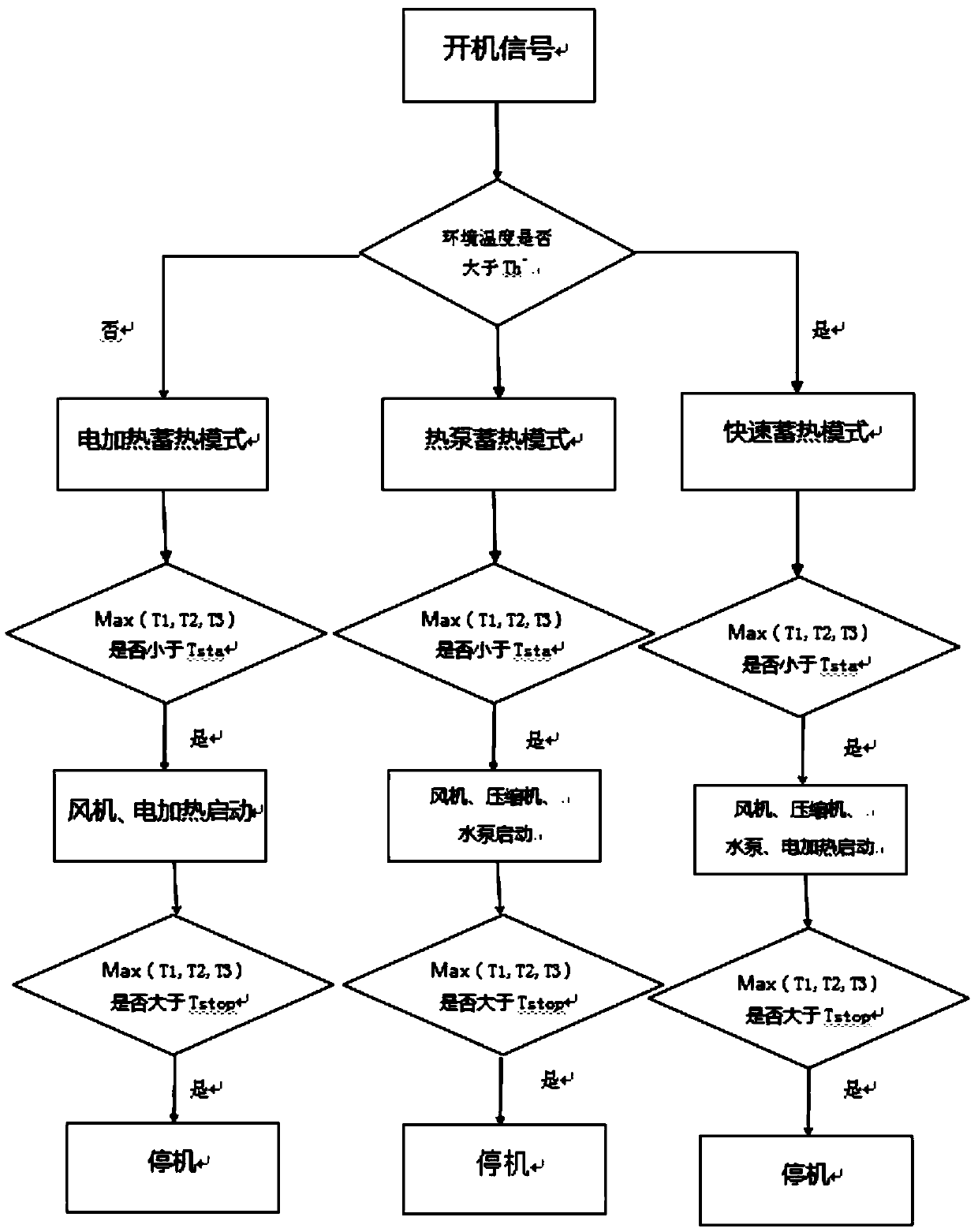

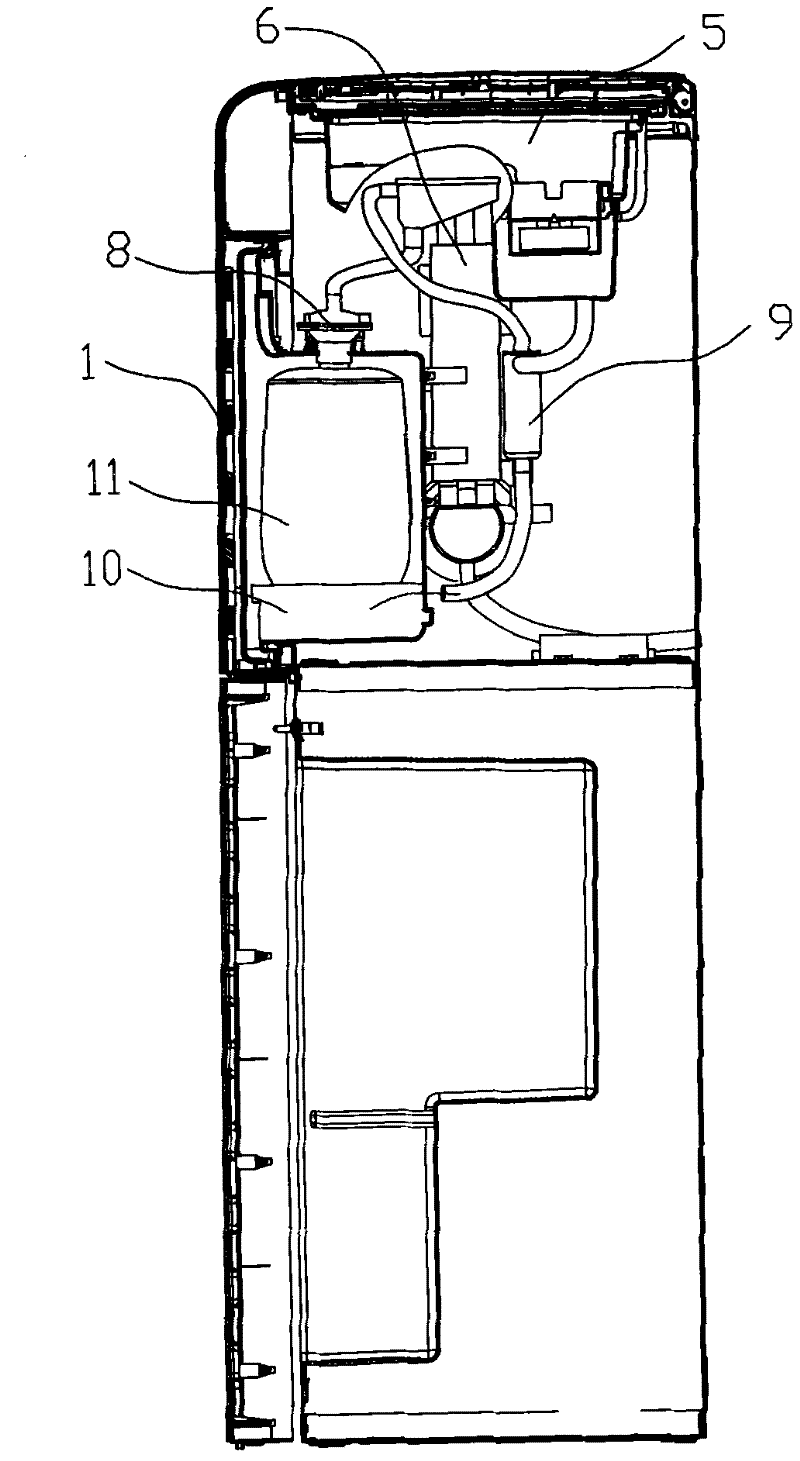

Low-temperature heat-storage water heater and heat storage control method and water application control method thereof

InactiveCN111197864AMeet different water needsTo achieve the purpose of energy savingFluid heatersCentral heating componentsWater useEngineering

The invention relates to the field of water heaters, in particular to a low-temperature heat-storage water heater and a heat storage control method and a water application control method thereof. A compressor, an evaporator and a condensation heat exchange pipe in a heat pump unit of the water heater are in serial connection into a refrigerant flow loop. A water tank is filled with a phase changematerial, a water supply pipe penetrates through the water tank, and the water supply pipe outside the water tank is provided with an electric heater. The condensation heat exchange pipe also penetrates through the water tank. A refrigerant in the condensation heat exchange pipe flows, and the phase change material is heated and turns into a liquid state from a solid state, so that heat storage isachieved. When the water needs to be heated, the phase change material releases heat and performs heat exchange with the water supply pipe. The phase change material can heat the water in real time,the size of the water heater is reduced, and the phase change material can store heat and save energy. When the water at the high temperature is used, a heat exchanger adopts electric heating, and through control of a heat pump system and an auxiliary electric heating structure, different water usage demands of users can be met. The electric heater is used for assisting in heating, the interior ofthe water heater is reasonably controlled, the water usage demand of the users is met, and the energy saving effect of the water heater with a heat pump is achieved to the greatest extent.

Owner:HEFEI MIDEA HEATING & VENTILATING EQUIP +1

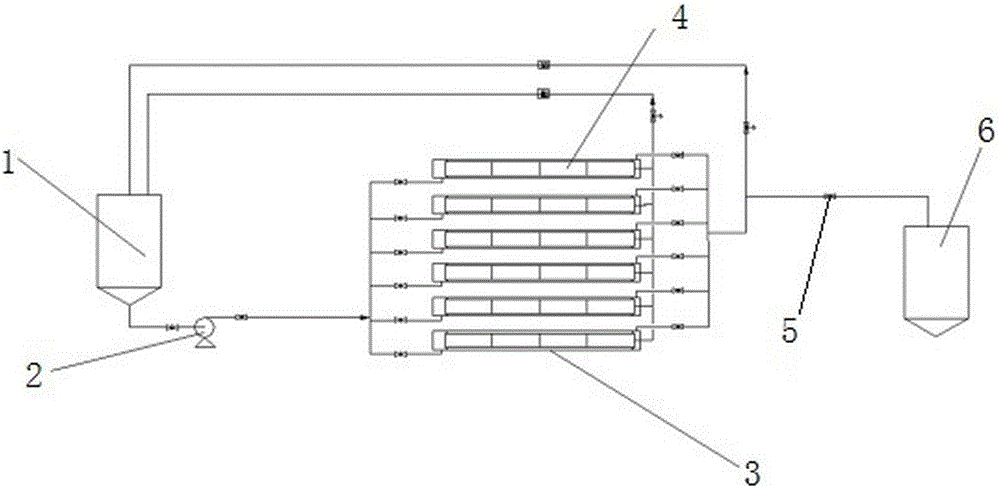

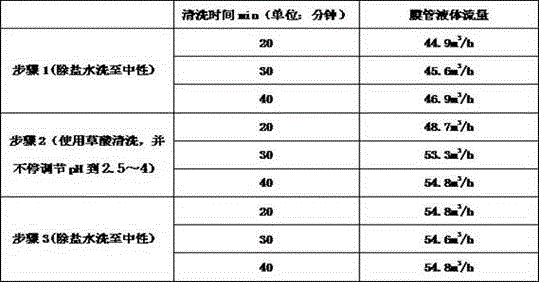

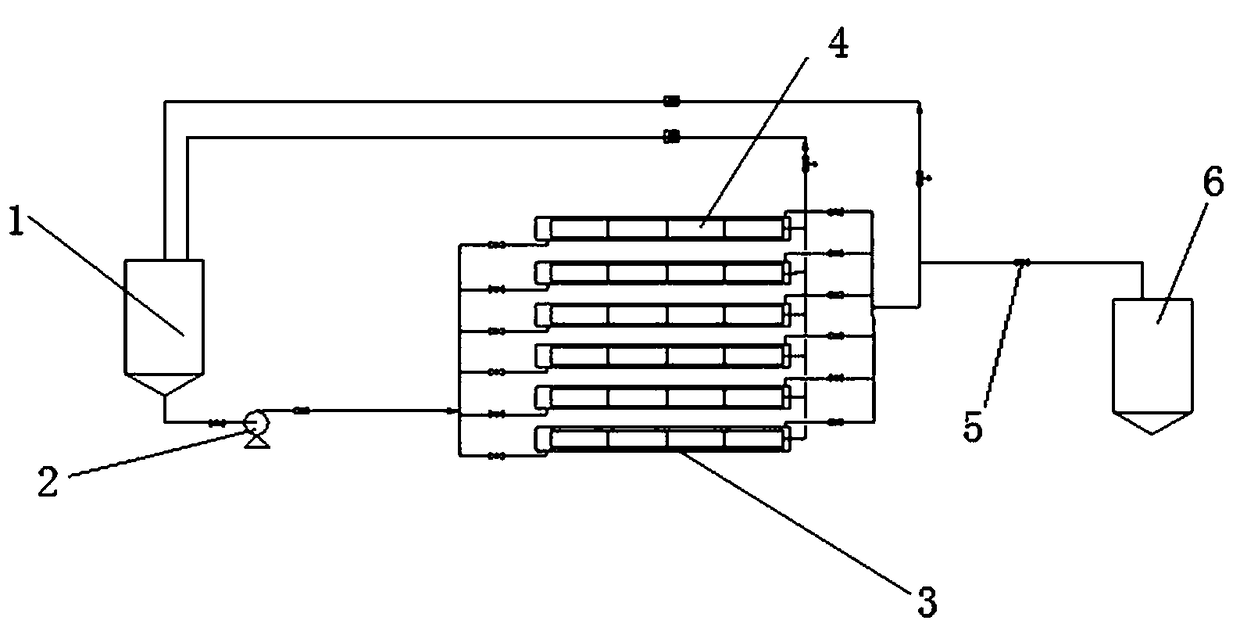

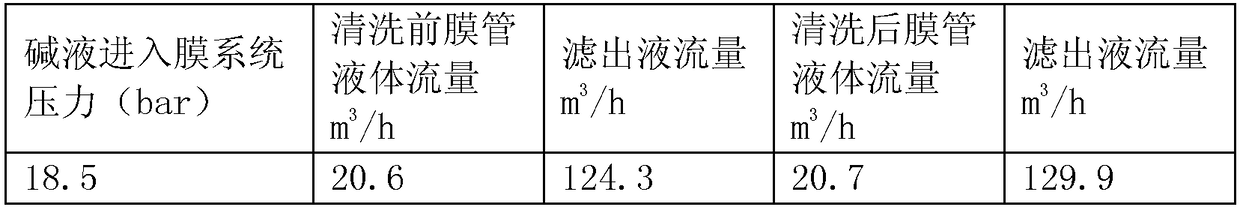

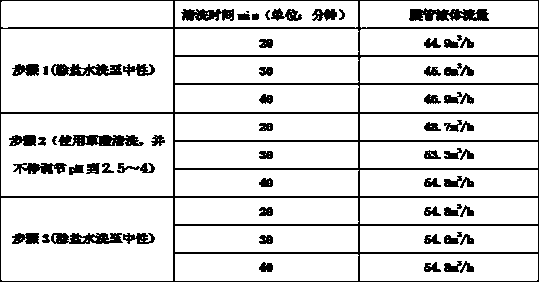

Nanofiltration membrane regenerating method

ActiveCN106268341AReal time heatingHigh trafficSemi-permeable membranesGeneral water supply conservationIonChemistry

The invention discloses a nanofiltration membrane regenerating method, relating to the field of viscose recovery. The method mainly comprises the steps of circularly cleaning demineralized water to adjust the demineralized water to be neutral, circularly cleaning an oxalic acid solution to remove hemicelluloses and impurities, and cleaning the demineralized water to adjust the demineralized water to be neutral again. By utilizing the washing-acid pickling-washing process, hemicelluloses accumulated in nanofiltration membrane holes can be effectively removed, divalent ions such as calcium, magnesium, ferrum and silicon form a complex to deposit the nanofiltration membrane subjected to secondary pollution in the cleaning process, so that the cleaned nanofiltration membrane achieves more than 93% of a rated value, and the regeneration of the nanofiltration membrane can be realized.

Owner:YIBIN GRACE +1

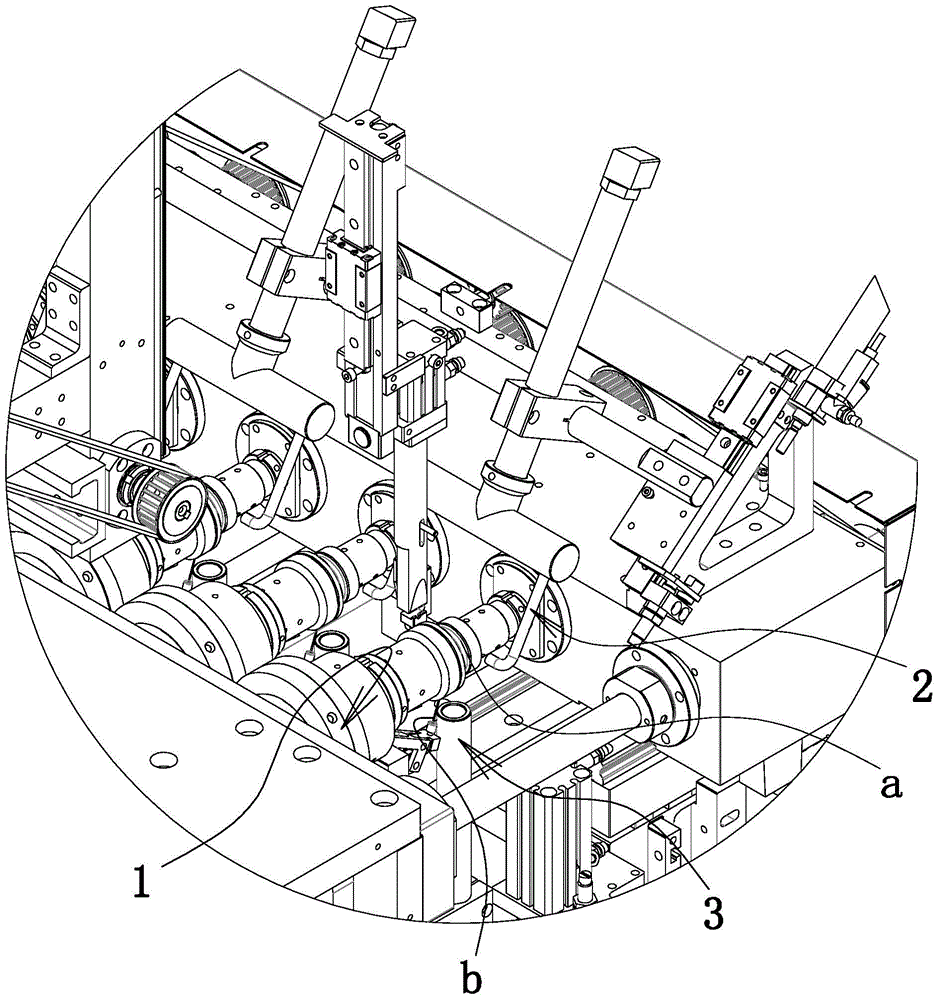

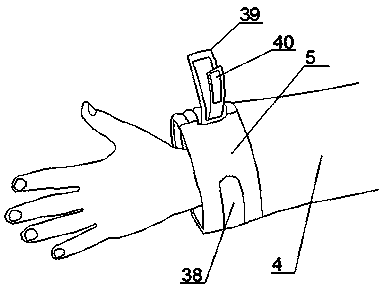

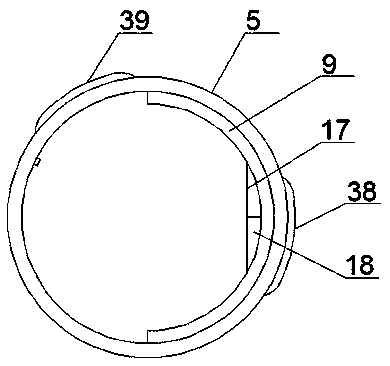

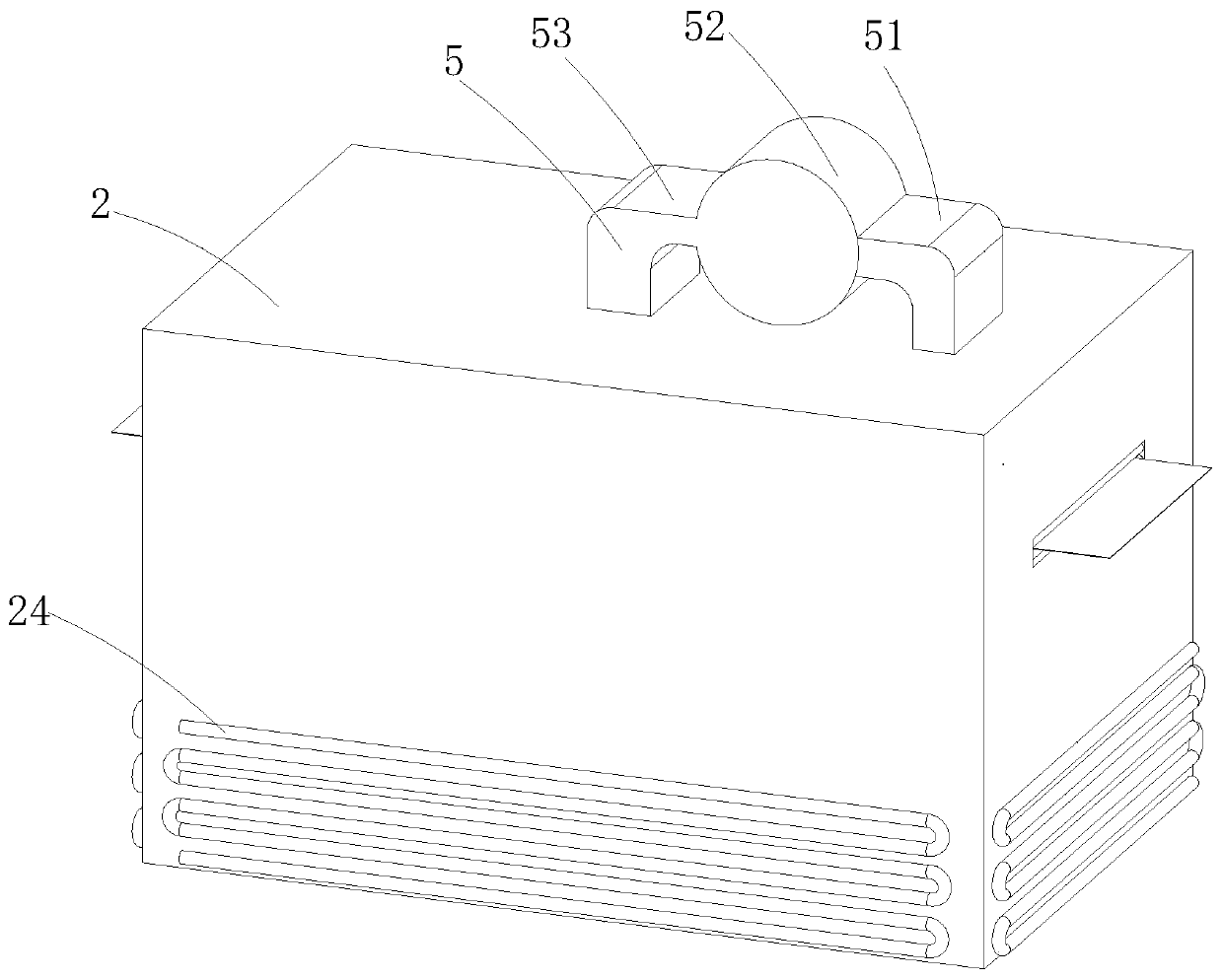

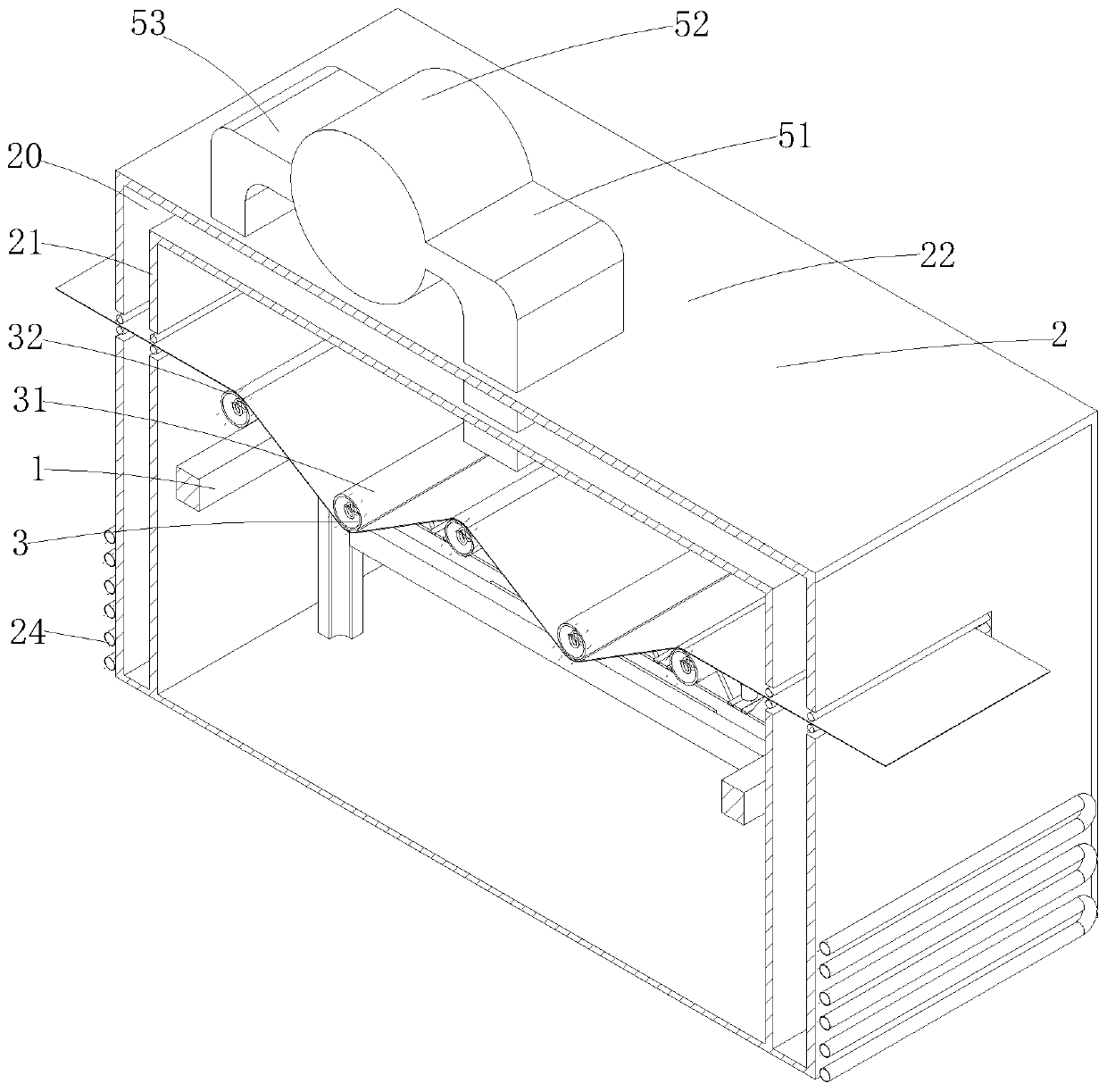

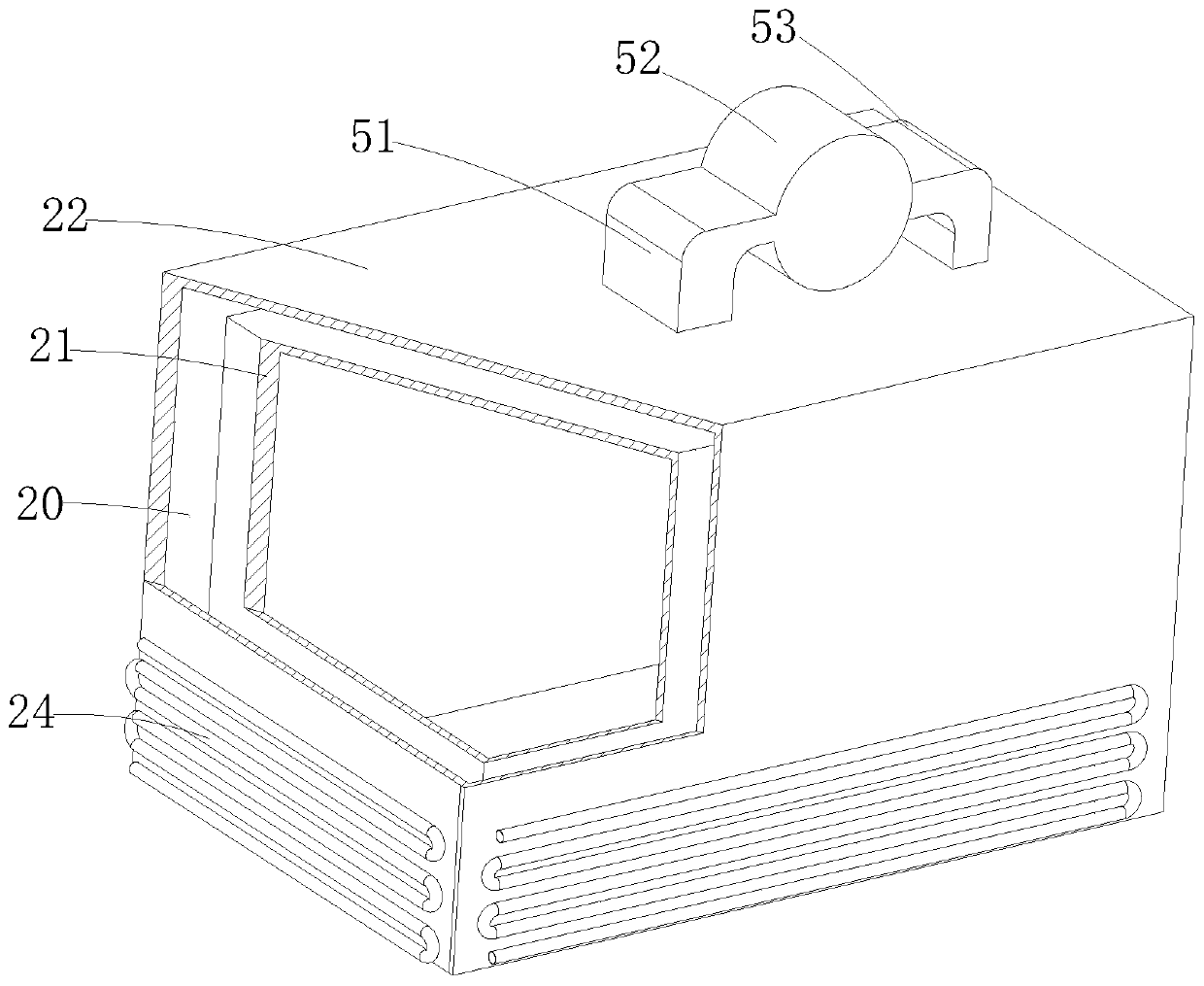

Heating system and heating method for dual-head hollow coil winding device

ActiveCN104916426AImprove practicalityReduce operating temperatureCoils manufactureState of artEngineering

The invention belongs to the technical field of winding devices, and in particular relates to a heating system and a heating method for a dual-head hollow coil winding device. According to the invention, the technical problems in the prior art, such as a poor heating effect, are solved. The heating system for a dual-head hollow coil winder comprises: a rotary preheating mechanism and a preheating apparatus, wherein when one end of a coiled wire rotates circumferentially around a winding jig and therefore the coiled wire is coiled on the winding jig, the rotary preheating mechanism can perform real-time heating on the coiled wire that is continuously coiled on the winding jig; and when the winding jig continuously coils the other end of the coiled wire and therefore the coiled wire is coiled on the winding jig, the preheating apparatus can perform real-time heating on the coiled wire that is continuously coiled on the winding jig. The system further comprises a heating apparatus that can perform heating on the coiled wire that is coiled on the winding jig. The heating method for the dual-head hollow coil comprises: driving rotary preheating. The system and the method have the advantage of a favorable heating effect.

Owner:TANAC AUTOMATION

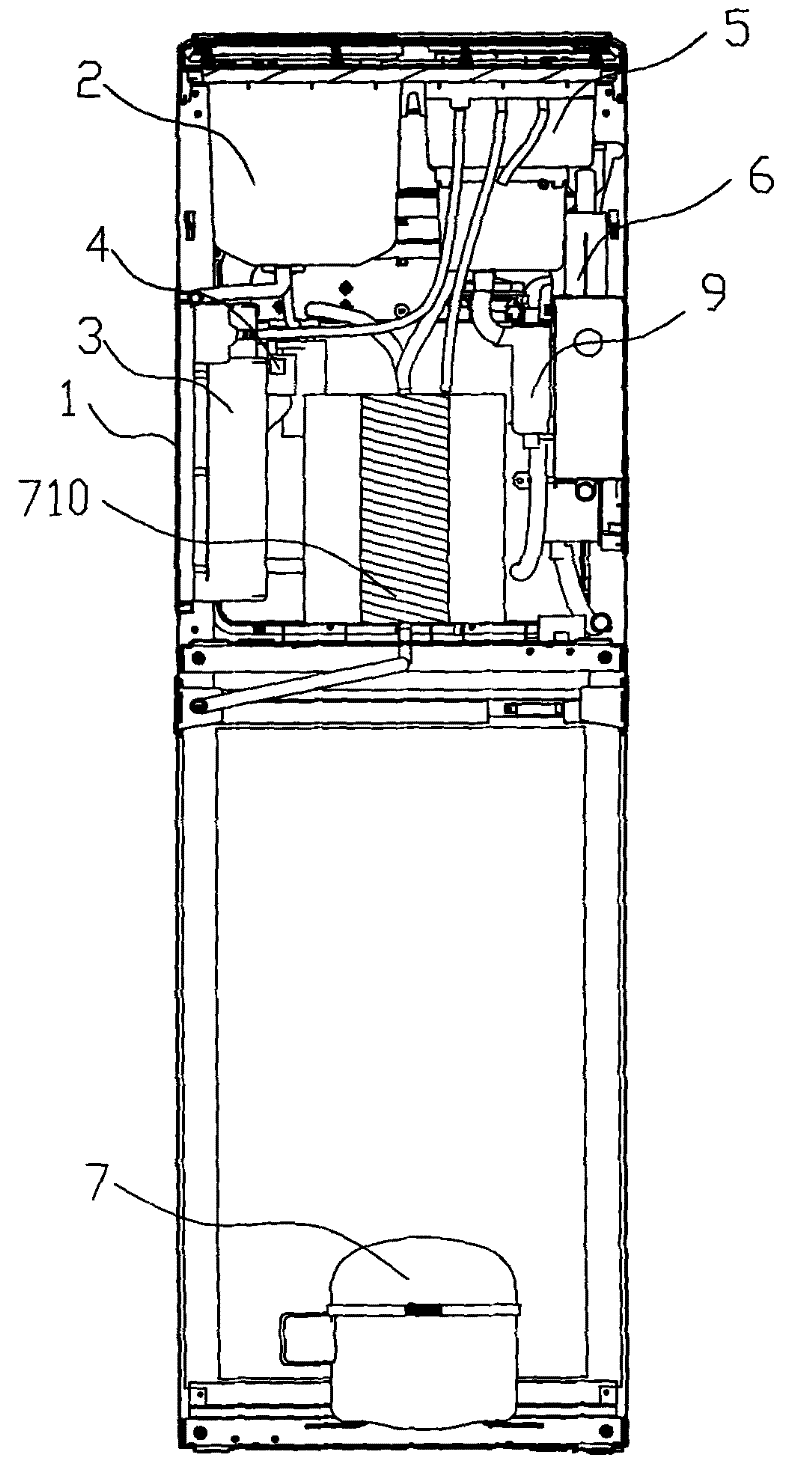

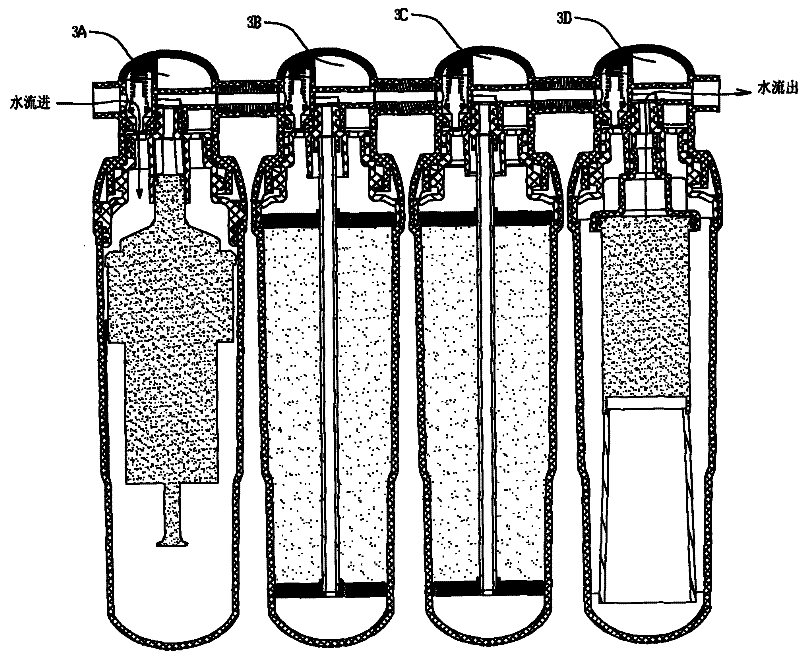

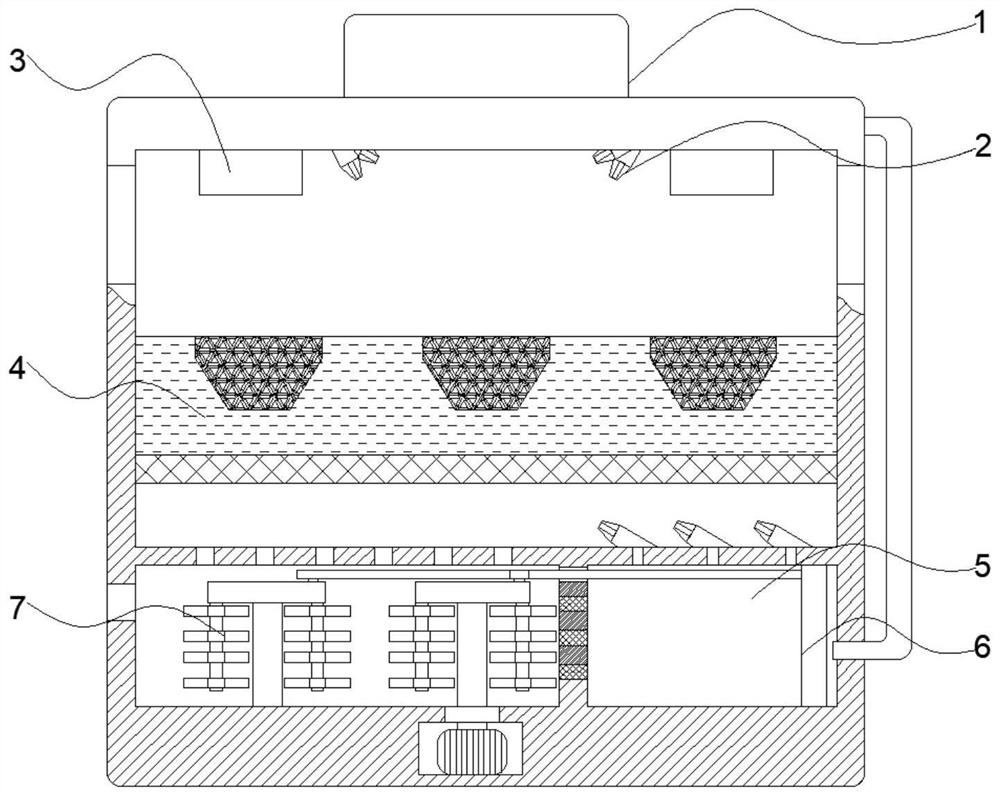

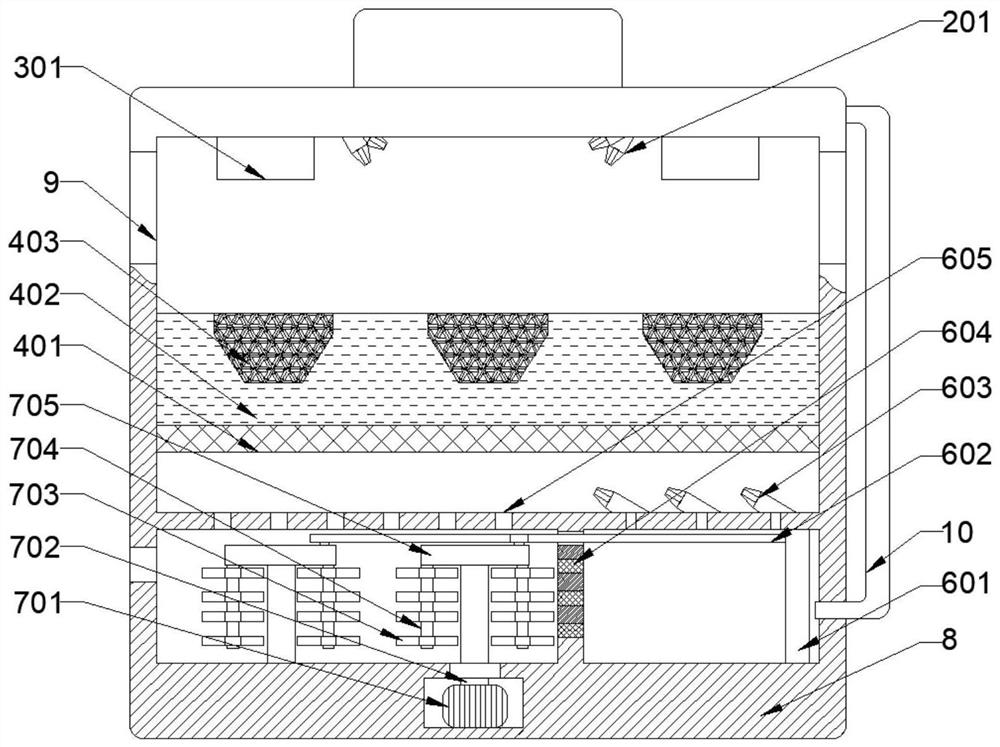

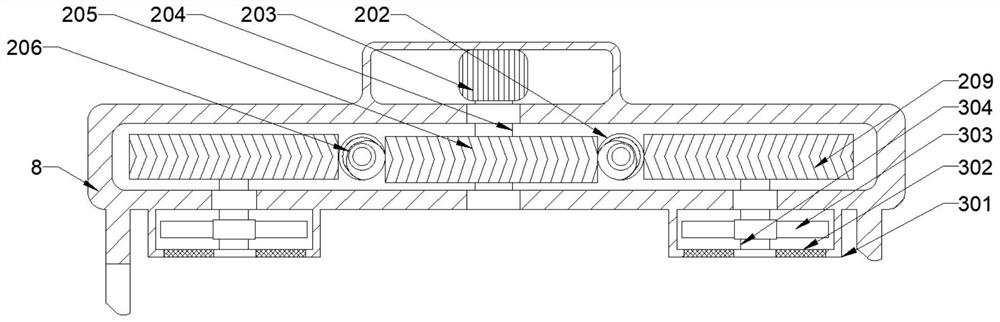

Water dispenser with purification device

InactiveCN102228360ARealize direct purificationEasy to useBeverage vesselsMultistage water/sewage treatmentUltrafiltrationActivated carbon filtration

The invention discloses a water dispenser with a purification device, which comprises a shell, a raw water tank, a purifier, a purified water tank, a cooling / heating device, a water outlet device and a waste water receiving box, wherein raw water firstly moves into the raw water tank; the raw water in the raw water tank is pumped into the purified water tank by a pump; the water in the purified water tank is subjected to cooling / heating treatment before being sent out by the water outlet device; the purifier is connected in series in a pipeline between the raw water tank and the purified water tank, and is formed by connecting an ultrafiltration purifier, a cation exchanger, an active carbon filter and a post-positioned ultrafiltration purifier in series; a filter cartridge cover and a filter cartridge of the ultrafiltration purifier form detachable flexible connection by means of a clamping lug of the filter cartridge cover and a corresponding bayonet of the filter cartridge; and the heating device comprises an electric heating membrane heater. By using the purification device, the raw water can be directly purified in the water dispenser, thereby facilitating the use process; as the ultrafiltration purifier has a detachable structure, the ultrafiltration membrane can be repeatedly cleaned and used, thereby saving the resources; and the electric heating membrane heater has a high heating efficiency, thereby achieving the effects of real-time water getting and real-time heating.

Owner:QINYUAN GRP CO LTD

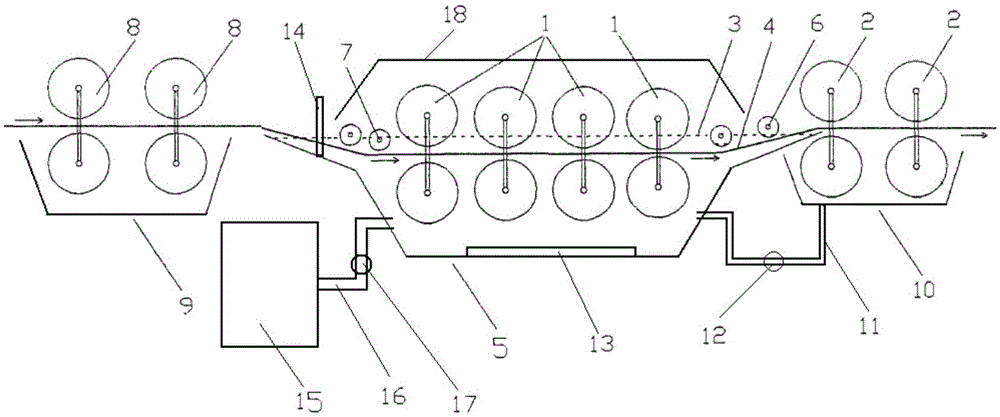

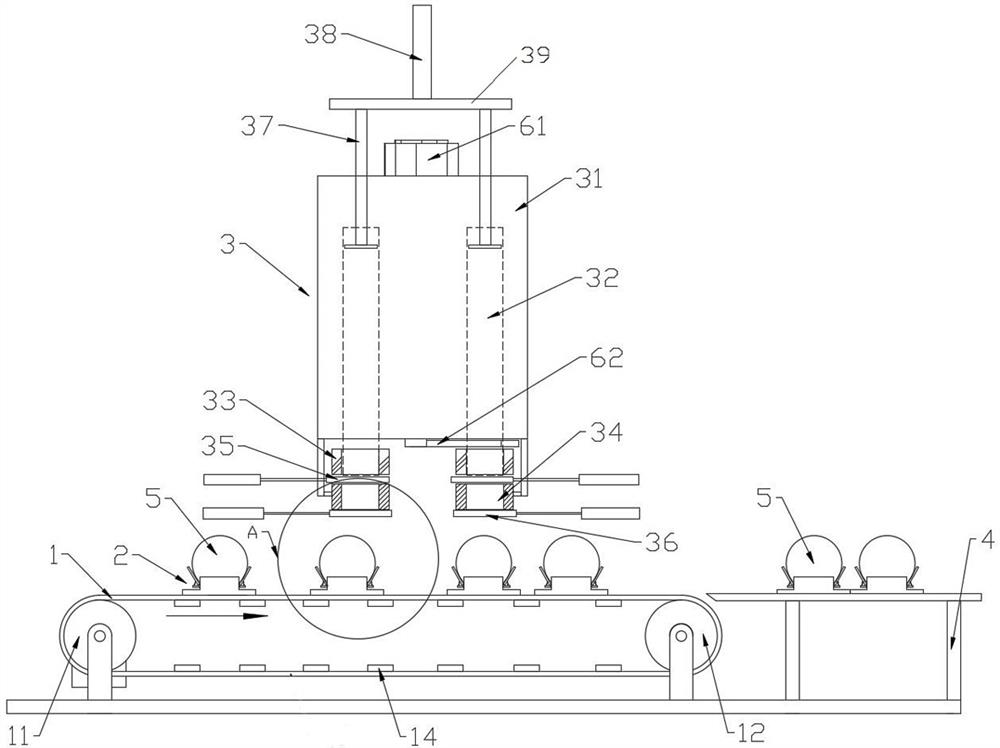

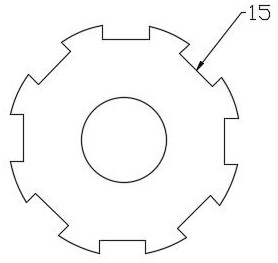

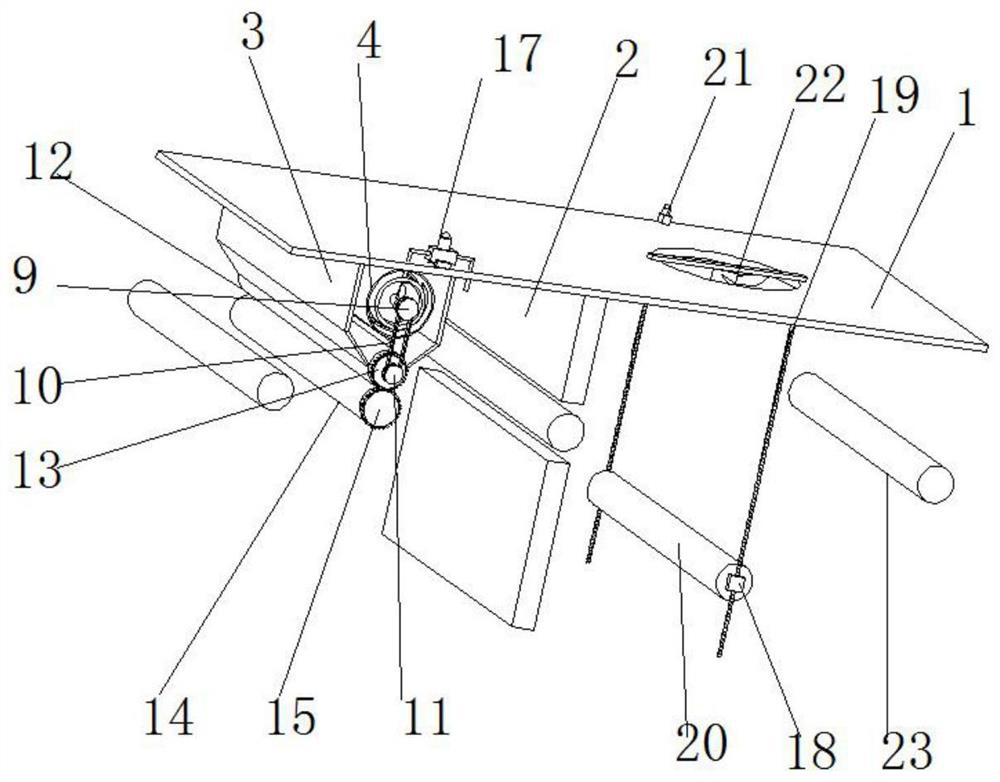

Machining device for rolling impregnation of wood and bamboo materials

InactiveCN105522626AReduce wasteReduce manufacturing costWood treatment detailsWood impregnation detailsExtrusionStorage tank

The invention relates to a machining device for rolling impregnation of wood and bamboo materials. The machining device comprises an impregnation roller set, a cleaning roller set and an impregnation tank; the impregnation tank is positioned below the impregnation roller set; the cleaning roller set is positioned on the right side of the impregnation roller set; a water extrusion roller set is additionally arranged on the left side of the impregnation roller set; one or more first guide rollers are arranged between the water extrusion roller set and the impregnation roller set; one or more second guide rollers are arranged between the impregnation roller set and the cleaning roller set; a modifying agent recovery device is arranged below the cleaning roller set; a heating device is arranged at the bottom of the impregnation tank; a temperature meter is arranged at the upper part of the impregnation tank; and a modifying agent storage tank is arranged on the left side of the impregnation tank. The machining device for rolling impregnation of the wood and bamboo materials has the following beneficial effects: the device can obtain the wood and bamboo materials uniformly impregnated by a modifying agent and with clean surfaces, can realize the assembly operation, and improves the working efficiency; and the assembly operation can reduce damage of the materials in the loading and unloading process.

Owner:BEIJING JMB SCI & TECH DEV LTD

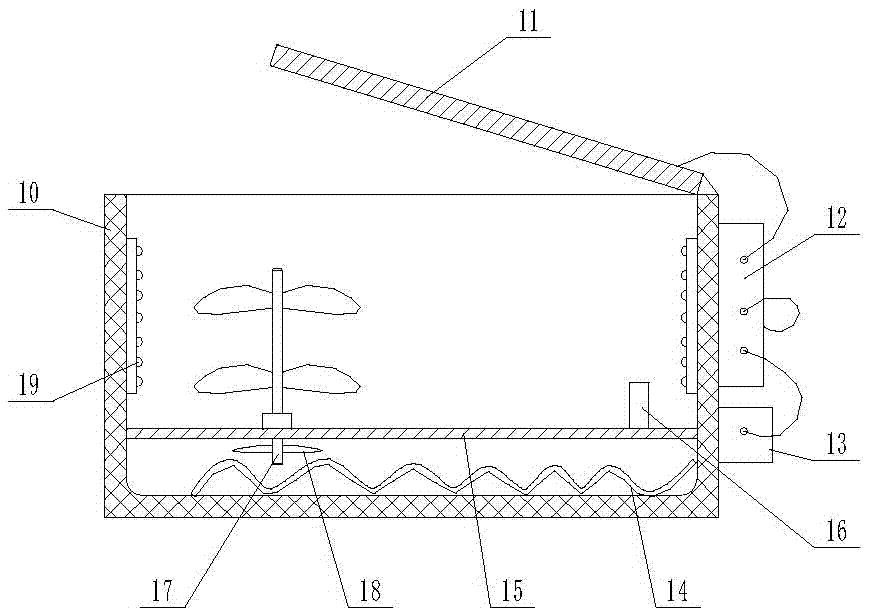

Solar panel culture pond

InactiveCN105432542AReduce lossIncrease water temperaturePisciculture and aquariaElectricityEngineering

The invention belongs to the technical field of fish culture and particularly discloses a solar panel culture pond which comprises a fish culture tank with an opening formed in the top. A solar panel is arranged at the top of the fish culture tank in an inclined mode. A current condenser and a controller are installed on the outer side face of the fish culture tank. The solar panel and the controller are electrically connected with the current condenser. A heating wire and a pore plate are installed at the bottom of the fish culture tank. The pore plate is arranged above the heating wire which is electrically connected with the current condenser. The culture pond has the advantage of increasing pond water temperature fast.

Owner:CHONGQING YINIU AGRI DEV CO LTD

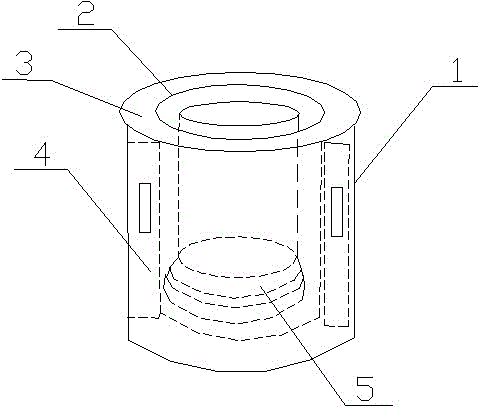

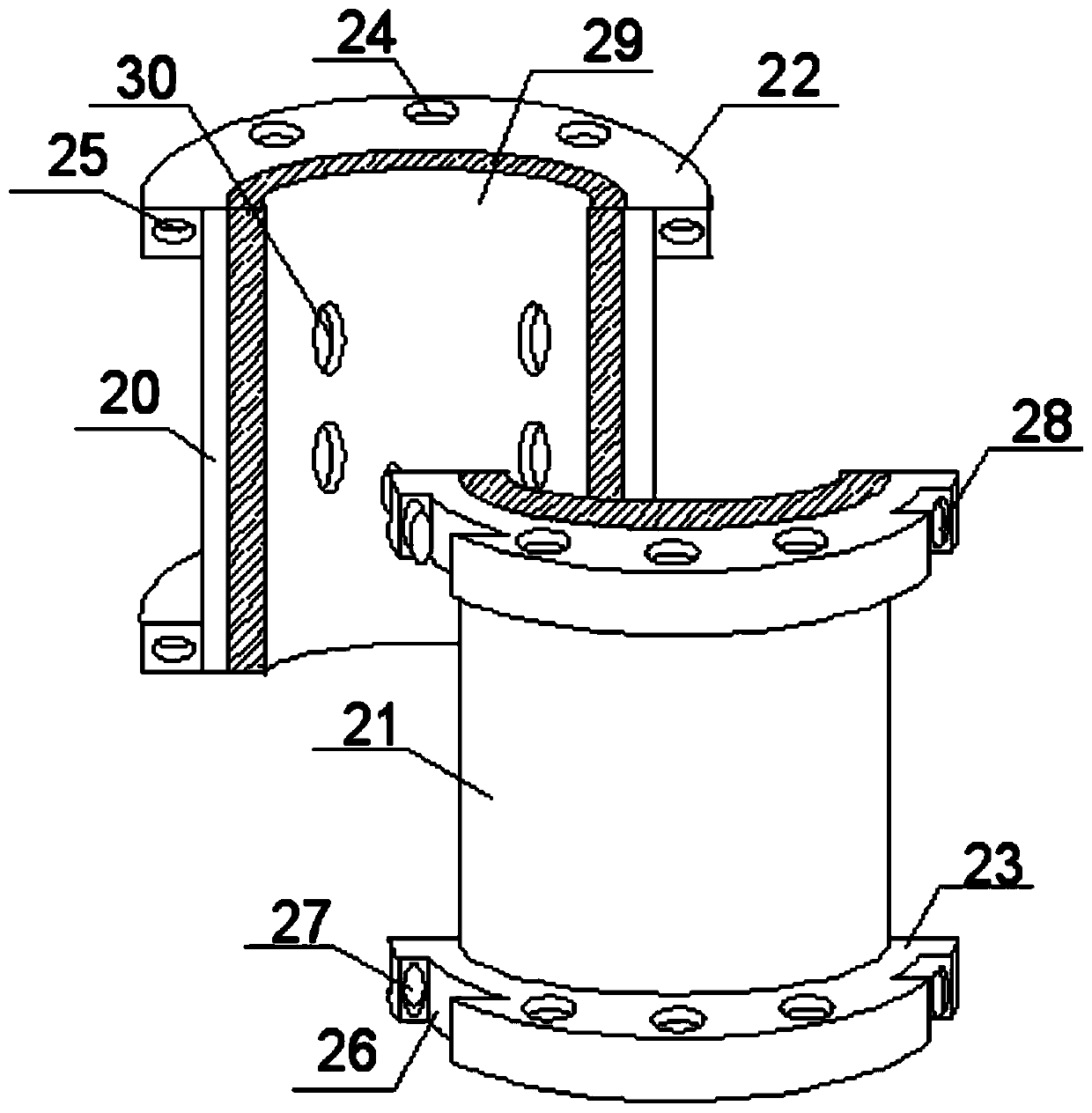

Oil viscosity detection device detection chamber

InactiveCN104697893AReal time heatingAvoid detection errorsFlow propertiesOil viscosityHeating system

The invention relates to an oil viscosity detection device detection chamber. The oil viscosity detection device detection chamber in the prior art only plays the role to place a sample cup, oil has the high viscosity, easy adhesion and other characteristics, so that the oil must be stored under the specific temperature conditions in order to avoid the detection error. The oil viscosity detection device detection chamber comprises a detection chamber body, the detection chamber body includes a columnar outer shell and an inner shell, the inner shell sleeves the outer shell, an annular hollow cavity is formed by the outer shell and the inner shell, a heat insulation device and a liquid detection sensor are arranged in the annular hollow cavity, and a heating system is arranged on the the inner shell bottom. The oil viscosity detection device detection chamber can heat the oil products in time, and ensures the oil is in needed test condition, and the error of the detection is avoided.

Owner:XIAN TIANHOU ELECTRONICS TECH

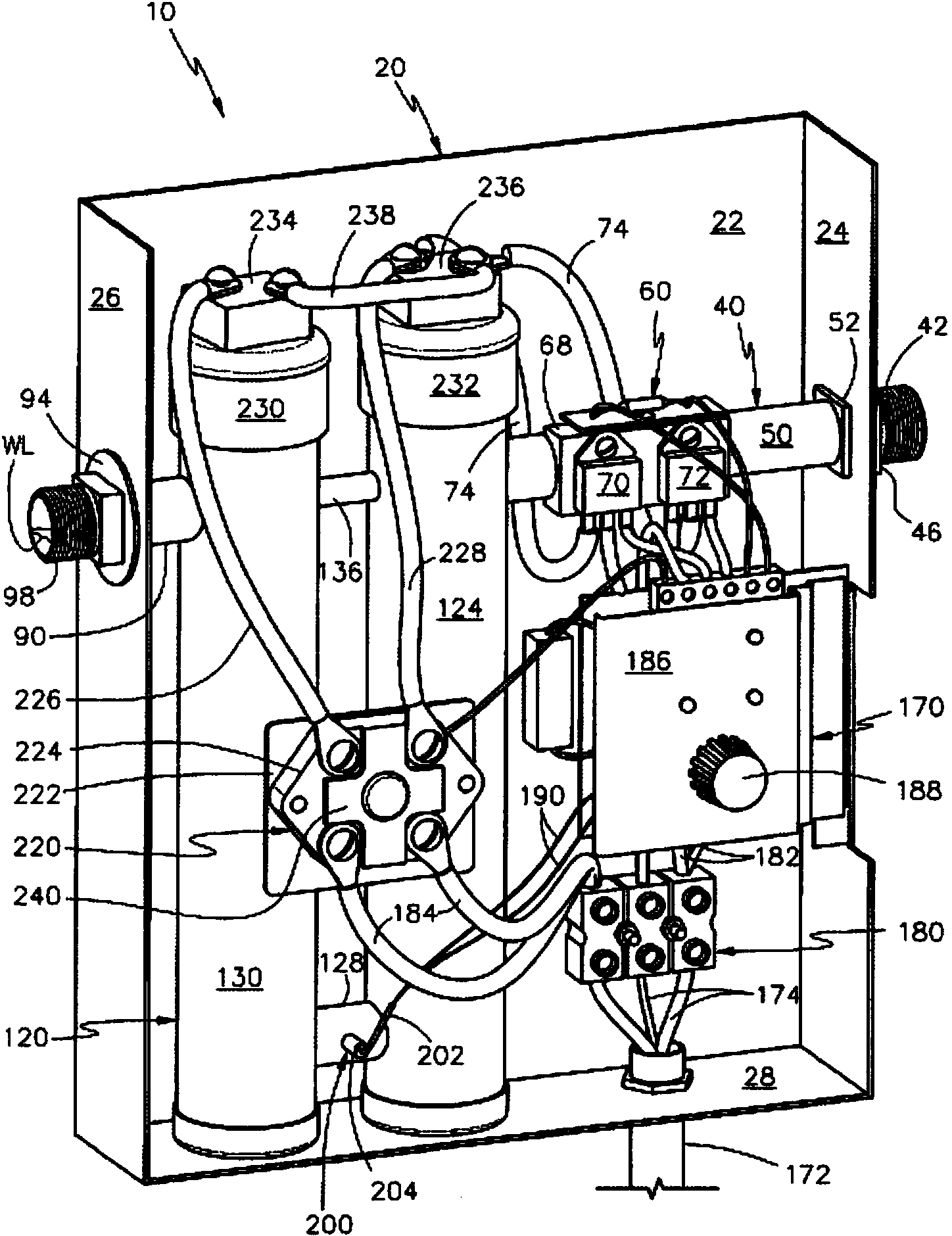

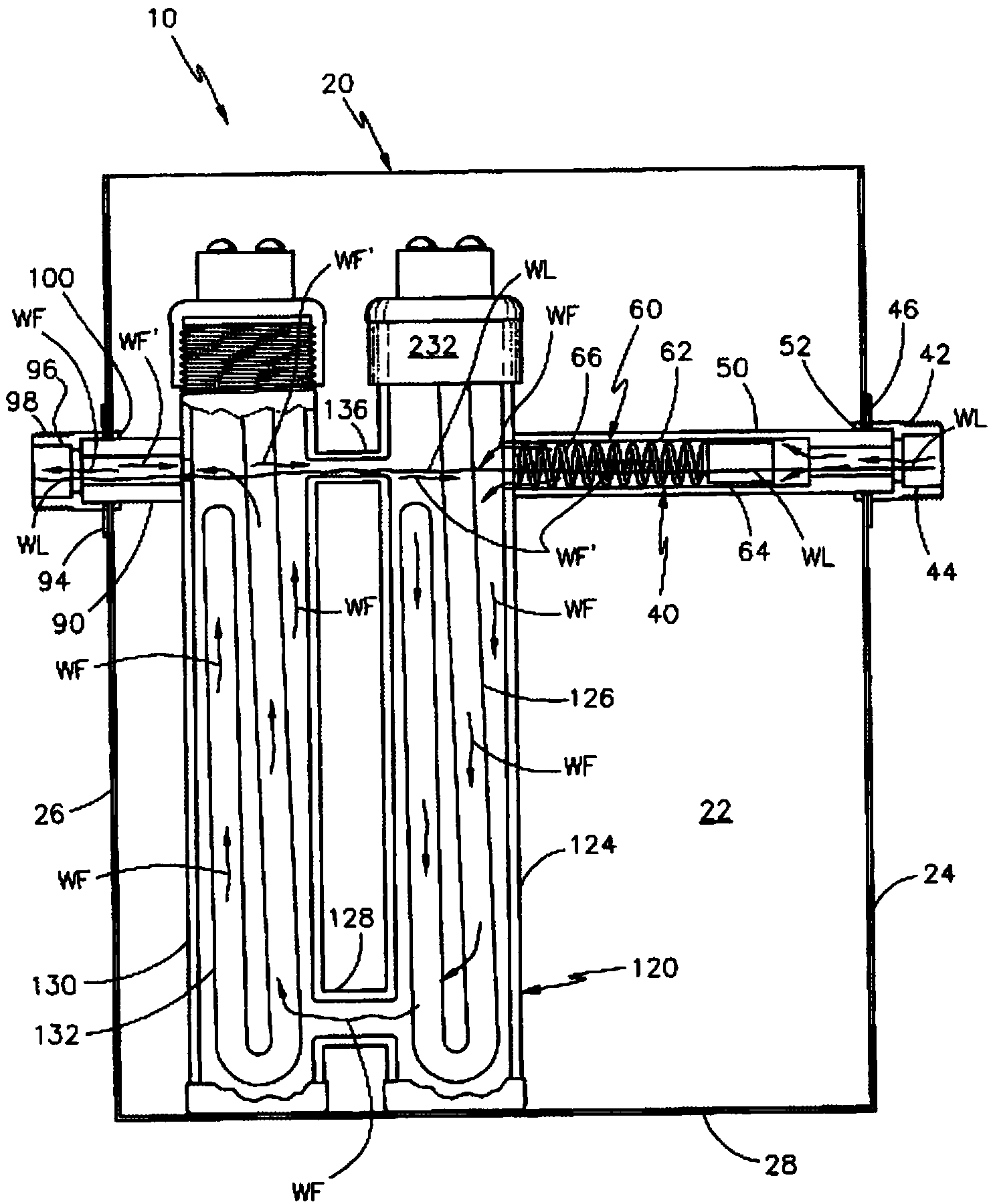

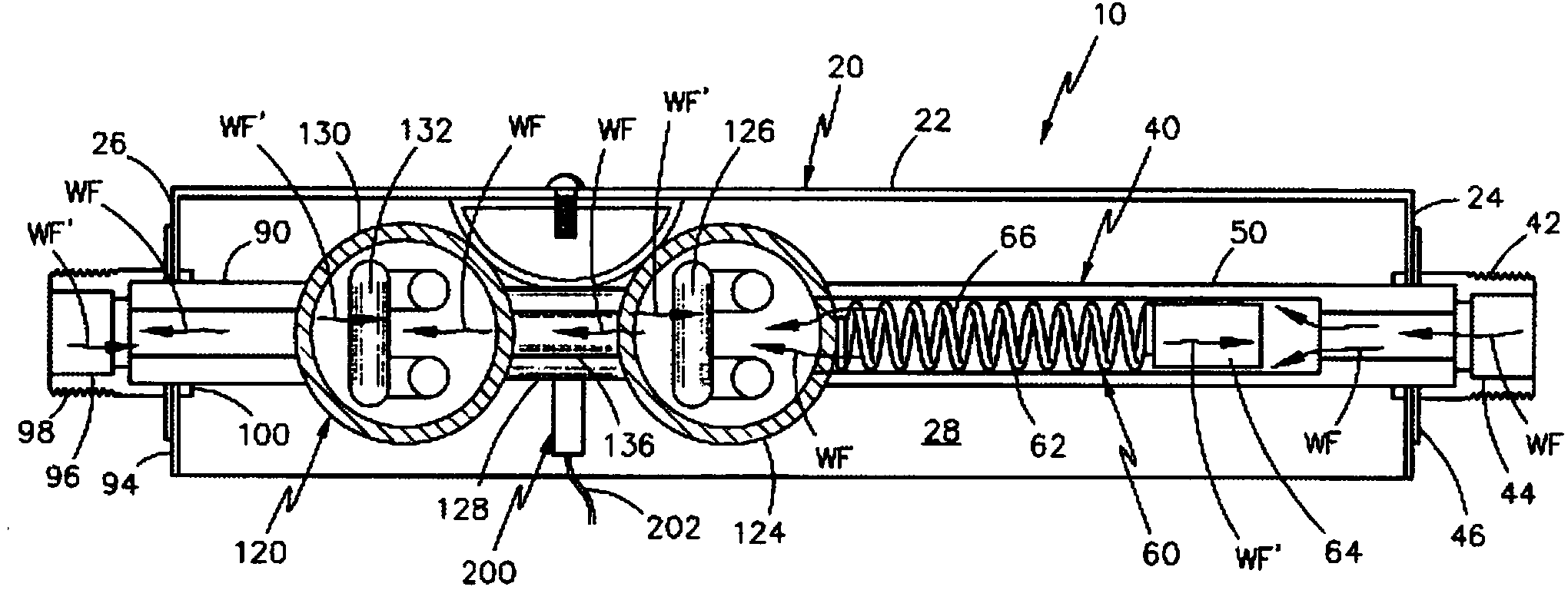

Tankless water heater assembly

ActiveCN104114956AReal time heatingEffective hot water methodImmersion heating arrangementsWater heatersWater sourceWater flow

A tankless water heating assembly (10) that heats water on a continuous basis as it passes from a conventional water source and through a heating system (120). It basically includes a housing assembly (20), a plumbing assembly (40), a heating system (120), and an electrical system (170). The tankless water heater assembly (10) heats water in a real time basis, as is being used, resulting in an efficient method of hot water utilization. The heating system (120) comprises heating elements (126 and 132) that are submerged within water as the water passes continuously through the heating units (124 and 130) to prevent heating unit (124) burnout, and the electrical system (170) has means (220) to properly measure water temperature as it is flowing within the heating system (120).

Owner:NIAGARA INDS +1

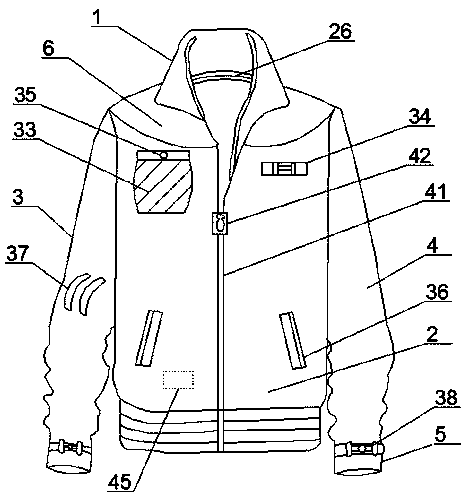

Thermal school uniform with cuffs capable of automatically changing heat retention property

InactiveCN110051058AReal-time heatingImprove comfortGarment special featuresElectrotherapySodium acetateEngineering

The invention discloses a thermal school uniform with cuffs capable of automatically changing the heat retention property. The school uniform comprises a shoulder collar and a uniform face located atthe bottom end of the shoulder collar, the first sleeve and the second sleeve are symmetrically arranged at the two sides of the uniform face, the bottom ends of a first sleeve and a second sleeve areeach provided with one cuff, a sealing inflation layer is arranged at the side, close to the shoulder collar, of the uniform face, a gas generator is arranged inside the sealing inflation layer, an impact inductor is arranged at one side of the gas generator, the bottom ends inside the first sleeve and the second sleeve are each provided with an interlayer, the interlayers are of U-shaped structures, bag bodies are arranged inside the interlayers, containers are arranged inside the bag bodies, the containers are filled with a super-saturated solution sodium acetate, heating blocks are arranged inside the containers, a first temperature sensor is arranged at one side of the top end inside each container, and the bag bodies are filled with water. The school uniform has the advantages that heating mechanisms are arranged inside the cuffs, the hands of a student can be heated in real time, the pen holding comfort level of the student is improved, the phenomenon that writing vibration is caused due to the fact that the hands of the student are cold is avoided, and the writing attractiveness and writing efficiency are improved.

Owner:福建玮祺服饰有限公司

Device for making Chinese hamburgers

ActiveCN111904016ARealize automatic meat clampingIncrease productivityFood coatingBiotechnologyEngineering

The invention discloses a device for making Chinese hamburgers. The device comprises a conveying belt for conveying horizontally, a plurality of clamping mechanisms for clamping opened white cakes anda feeding mechanism for storing sauced meat, wherein the feeding mechanism is arranged at a feeding station above the conveying belt; the clamping mechanisms are arranged on the conveying belt at equal intervals; the white cakes are vertically arranged on the clamping mechanisms; the conveying belt can drive the clamping mechanisms to reach the feeding station below the feeding mechanism; and thefeeding mechanism can inject sauced meat into the white cakes. The device can realize real-time automatic filling of Chinese hamburger with sauce meat, is uniform in filling, guarantees good taste, and improves the making efficiency.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

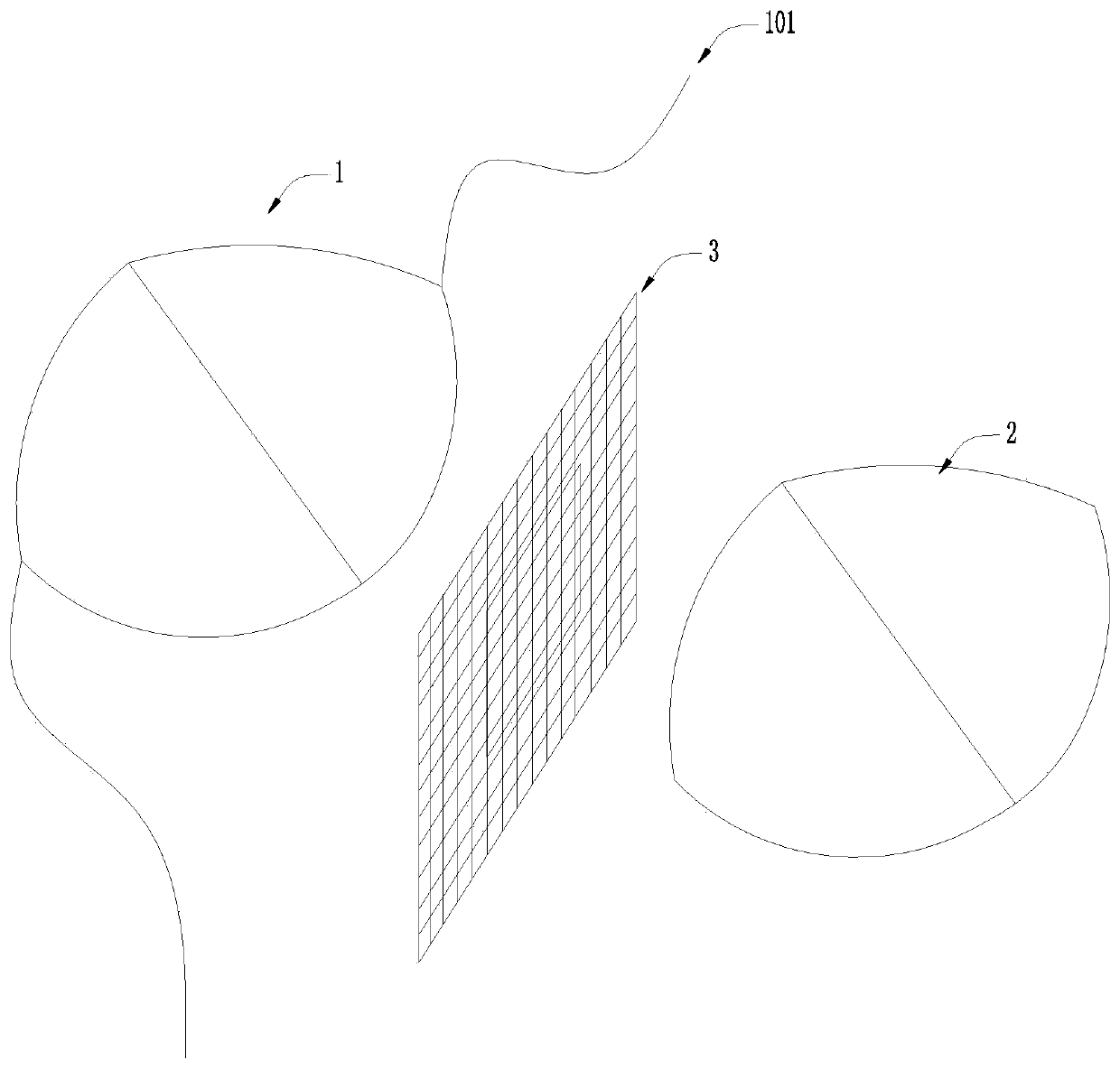

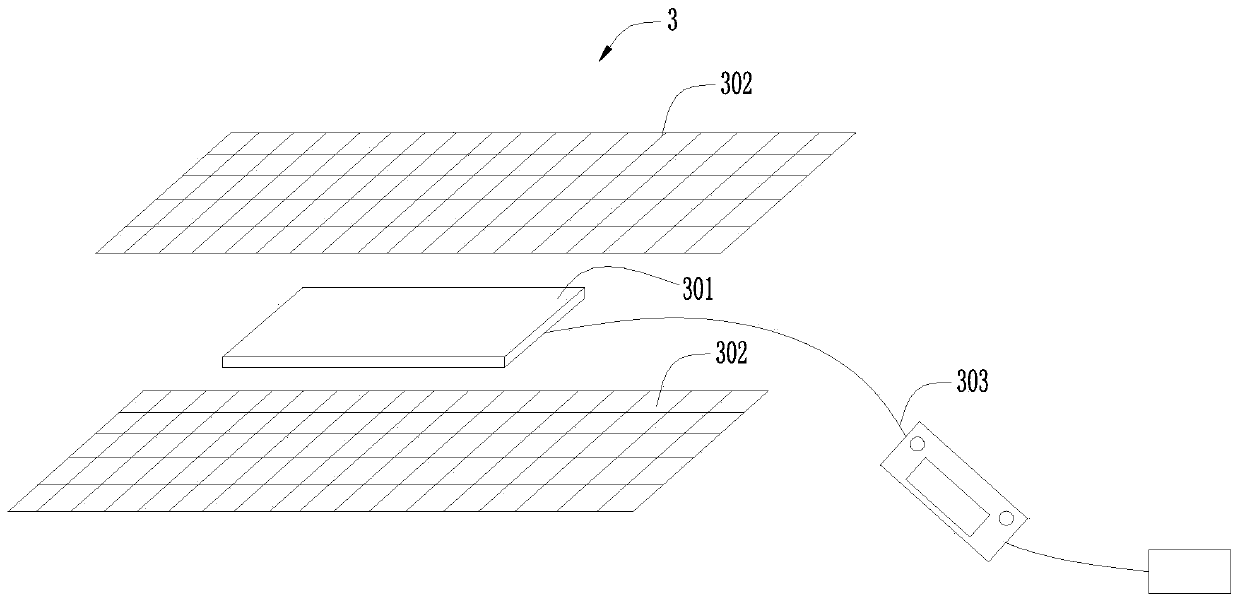

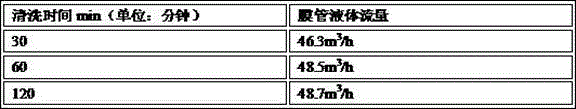

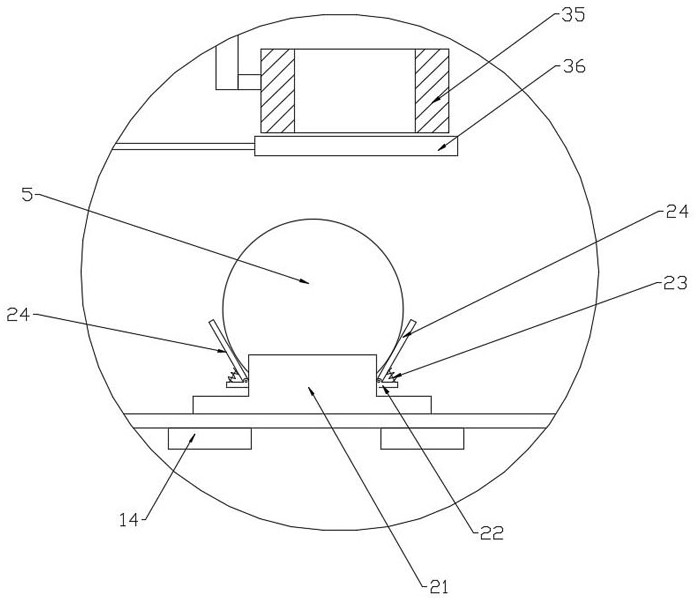

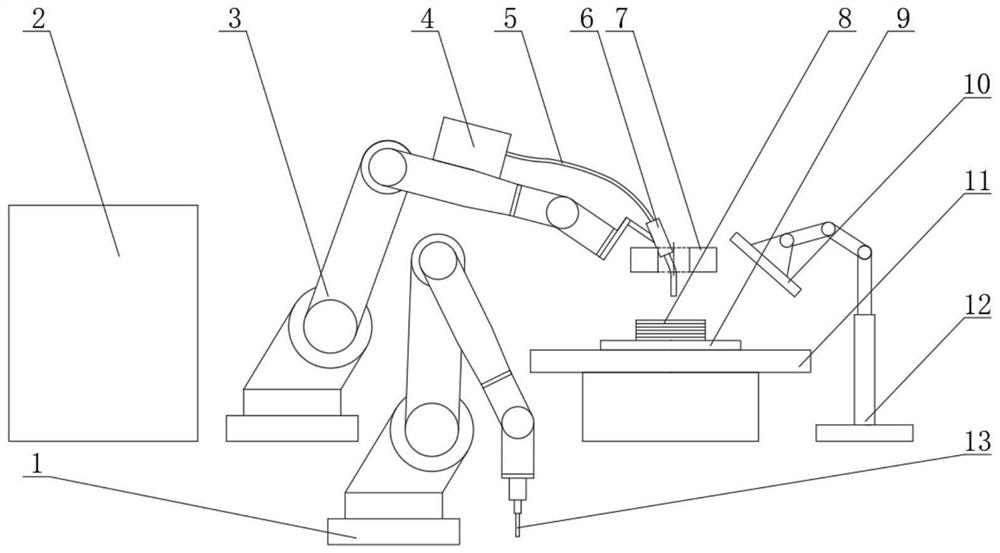

Substrate-formed part preheating device and method of additive and subtractive manufacturing equipment

InactiveCN112548581AShorten the manufacturing cycleReduce local warmup timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeating furnace

The invention discloses a substrate-formed part preheating device and method of additive and subtractive manufacturing equipment. According to the device, a far-infrared heating technology is used, non-contact preheating is performed on a substrate and a formed part through a plate-shaped far-infrared heater and an annular far-infrared heater, the plate-shaped far-infrared heater is used for global preheating, the annular far-infrared heater is used for local preheating, global preheating can conduct auxiliary heating on local preheating of the formed part, the plate-shaped far-infrared heaterand the annular far-infrared heater operate cooperatively, local preheating time is shortened, and additive efficiency is improved. Compared with induction heating, furnace heating and other technologies, the device has the advantages that the far-infrared heating technology is safe, efficient and low in cost, and the purposes of shortening the manufacturing period of large and medium structuralparts, reducing the labor cost and increasing the economic benefits can be achieved.

Owner:XI AN JIAOTONG UNIV

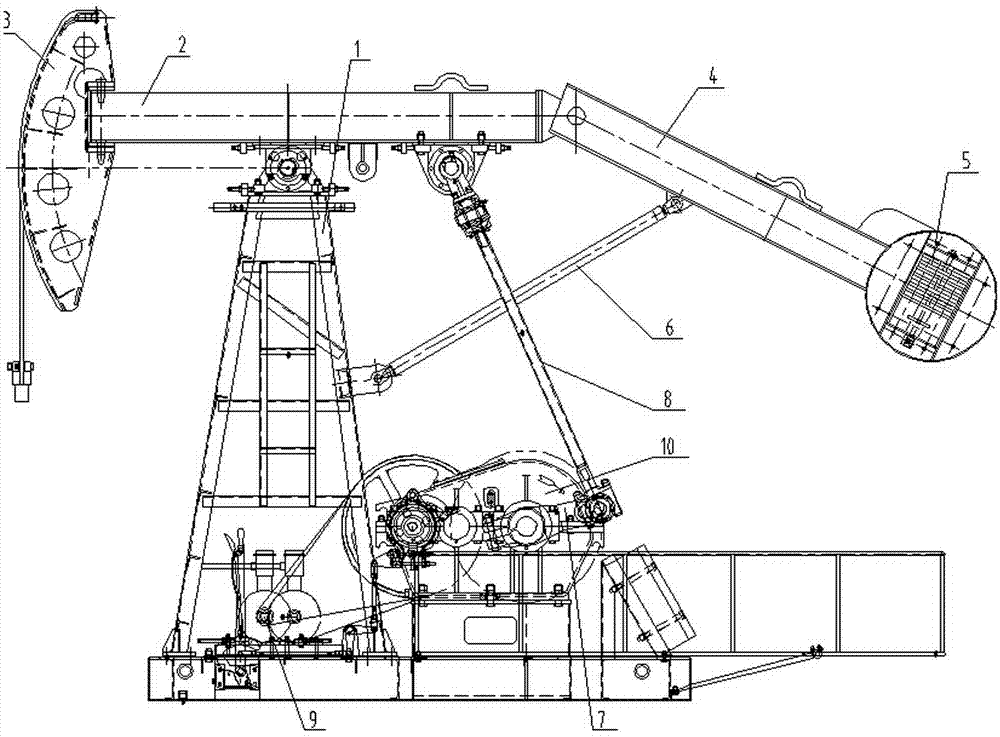

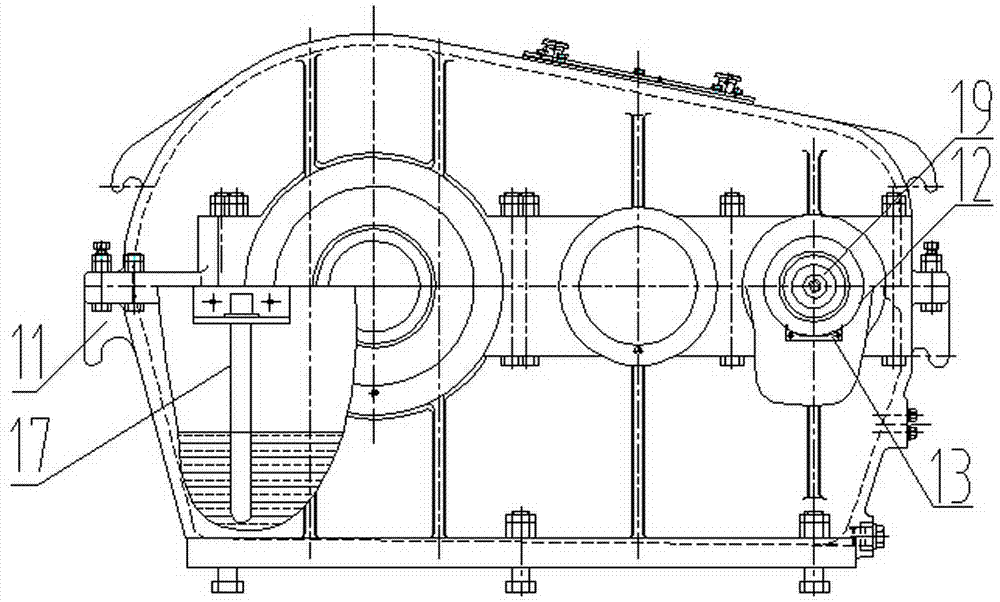

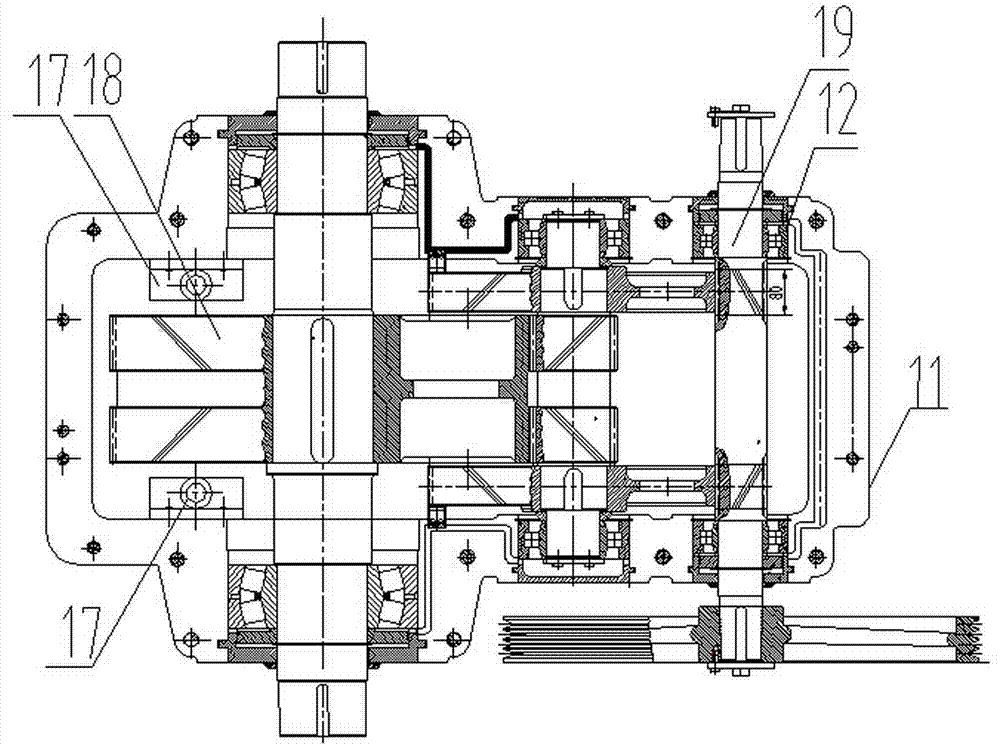

Beam-pumping unit

The invention discloses a beam-pumping unit, which comprises a bracket, a reducer, a crank, a connecting rod, a beam, a horse head, constant-temperature heaters, a balance arm, a balance block and a supporting rod, wherein the beam is movably connected to the bracket; the horse head is fixedly arranged on one end of the beam; the balance arm is movably connected to the other end of the beam; the balance block is fixedly arranged on the balance arm; one end of the support rod is movably connected to the bracket; the other end of the supporting rod is movably connected to the balance arm; the reducer is connected with the crank; the connecting rod is movably connected between the crank and the beam; the constant-temperature heaters are fixedly arranged in the tank body of the reducer for heating lubricating oil. The beam-pumping unit has the two technical advantages that the peak value current of a motor can be reduced when the horse head moves to an upper stop, the peak value current of a motor and the valve current torque of the reducer are reduced when the horse head moves to a lower stop, and the lubricating oil in the reducer can be prevented from icing or becoming a thick state under a low-temperature state.

Owner:SICHUAN JINXIN CO LTD

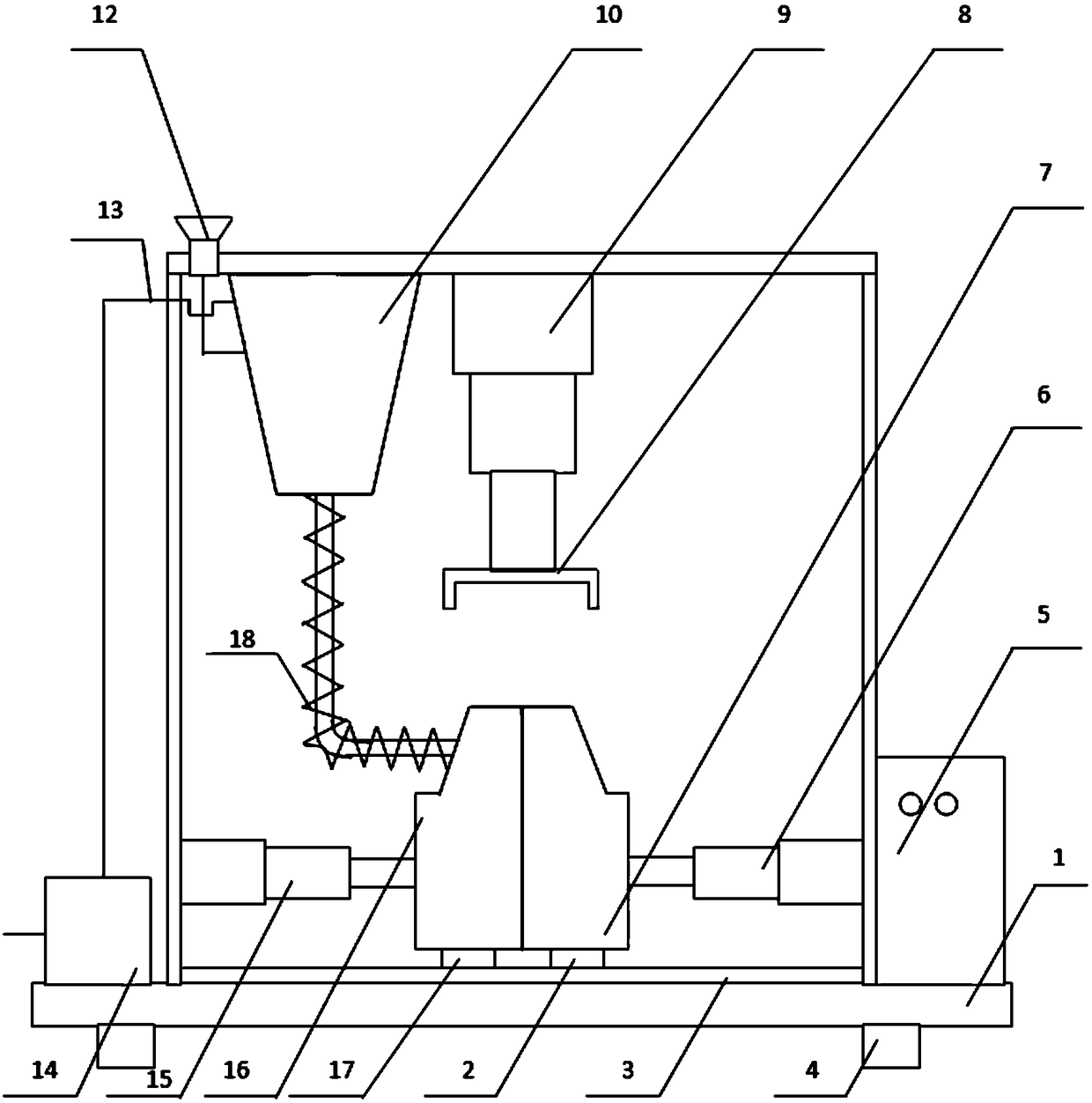

Die-casting machine

The invention discloses a die-casting machine which comprises a rack, a first sliding block , a guide rail, foots, an electric cabinet, a first extrusion device, a first die body, a cohesion device, asecond extrusion device, a hopper, a feeding hole, a liquid inlet pipe, a washing device, a third extrusion device, a second die body, a second sliding block and a heating wire, wherein the foot arefixedly arranged on the lower surface of the bottom plate of the rack and is in contact with the ground; the washing device is arranged on the bottom plate of the rack; and the liquid inlet pipe is fixed on the side face of the rack and is connected with the washing device. The die-casting machine can heat alloy liquid in a pipeline in real time to keep the alloy liquid to be at the temperature most proper for casting and to prevent the problems about misrun and cold shut of a casting due to too low temperature of the alloy liquid. In addition, after casting, the washing device can wash the hopper and the pipeline to prevent the situation that impurities in the hopper are mixed with the alloy liquid to affect the casting quality when casting is carried out once more.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

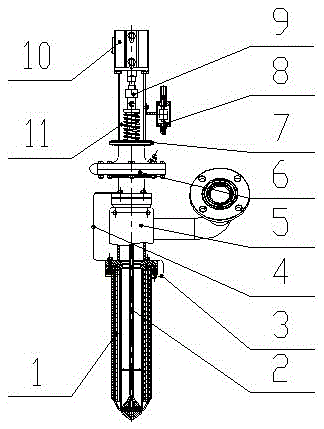

Integral sealing type electrical heat tracing anti-explosion material filling head

InactiveCN105523209AReal time heatingRealize electric heating functionLiquid materialPhysicsEngineering

An integral sealing type electrical heat tracing anti-explosion material filling head comprises a sealing jacket integral electrical heat tracing material filling rod, a valve element, a three-way body, a sealing assembly and a sensor and is characterized in that the sealing jacket integral electrical heat tracing material filling rod comprises a heat conducting belt, an electrical heat tracing belt, an upper pressing plate, a lower protective sleeve, an outer protective sleeve and an inner protective sleeve, wherein the electric heat tracing belt penetrates through a groove of the lower protective sleeve, and the heat conducting belt is wound on the outer wall of the inner protective sleeve. The integral sealing type electrical heat tracing anti-explosion material filling head has the advantages that according to material characteristics and the operation temperature requirement during filling, real-time heating is achieved through adjustment with a central control system; through cooperation among the inner protective sleeve, the outer protective sleeve, the heat conducting belt, the electrical heat tracing belt, a fixing belt and an outer heat insulating belt, the effect of heat insulation and the effect of insulating anti-creeping protection are realized while the electrical heat tracing function is realized.

Owner:CHANGCHUN BEIFANG INSTR EQUIP

Sitting bath device for vaginal inflammation reduction

The invention discloses a sitting bath device for vaginal inflammation reduction. The sitting bath device comprises a bath seat with a slot structured chair seat as the main body, a basin structured bathtub is arranged in the slot bottom of the chair seat, a slot structured drainage groove is formed in the middle of the bottom of the bathtub, a sealing cover I is buckled in the drainage groove, atubular drainage pipe is fixedly connected to the lower end of the drainage groove, a cavity structured avoidance cavity is arranged in the lower end of each of the bath seat and chair seat, and the inner wall of the chair seat is provided with a guide hole to the outside of the bath seat; the chair seat and the back of the same provide a good support to the patient's body, the patient's waist canbe supported more comfortably by adjusting the fluctuation of an air cushion, and comfort of in patient's use is improved; liquid in the bathtub can be heated through a heating seat in real time to ensure that the liquid in the bathtub is maintained at a suitable degree of heat, which is beneficial to the recovery of patient's wound.

Owner:HUZHOU MATERNITY & CHILD CARE HOSPITAL

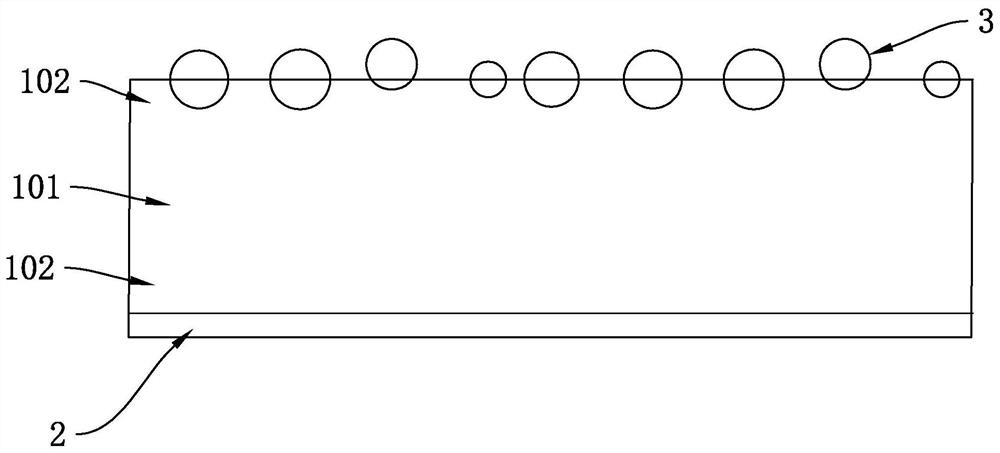

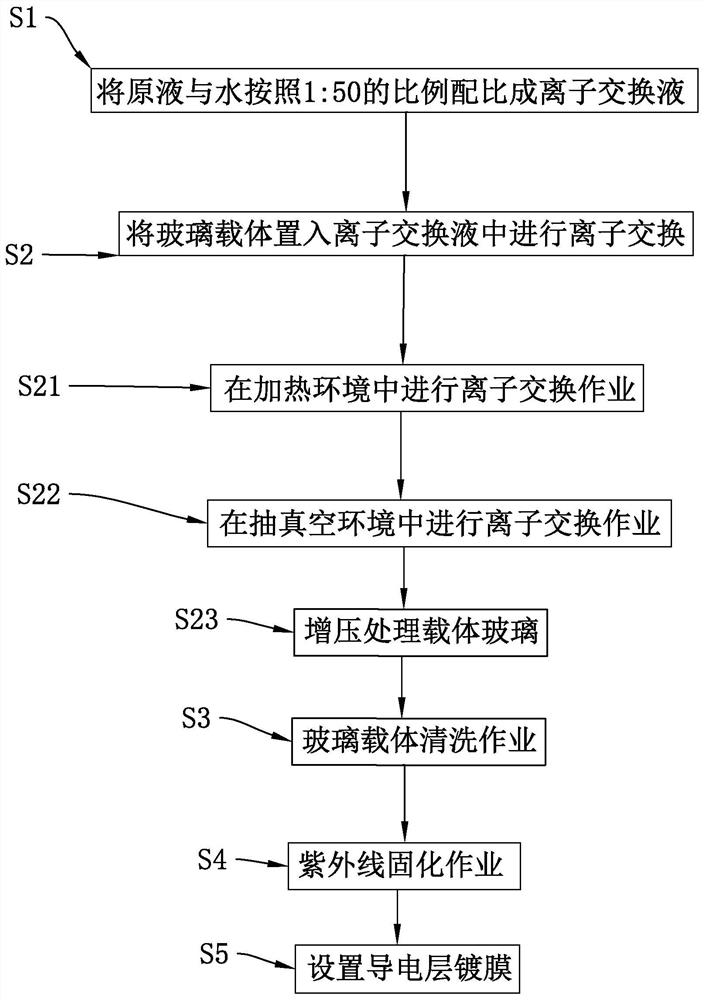

Sterilization and virus killing method based on flexible glass

InactiveCN111844965AProlong the action timeWith sterilizationSynthetic resin layered productsDeodrantsMedicineIon exchange

The invention discloses a sterilization and virus killing method based on flexible glass. The invention relates to the technical field of sterilization and virus killing. A piece of flexible glass isput into ion exchange liquid, and vacuumizing, heating, assisted ultrasonic oscillation and electroplating are carried out to embed cations into gaps among silicon dioxide atoms on the surface of theflexible glass, and the cations are stably fixed on the surface of the flexible glass through ultraviolet curing. In this way, a cation sterilization and virus killing layer for sterilization and virus killing is formed on the surface of the flexible glass. The other side of the flexible glass is electroplated to form a conductive layer coating film, the conductive layer coating film is connectedwith an external power supply, the flexible glass is heated, the temperature of the flexible glass is rapidly increased to 60 DEG C or above, the temperature is kept at 65-75 DEG C for a certain period of time in real time, and high-temperature sterilization and virus killing are achieved. Finally, die cutting and plastic molding are carried out on the flexible glass to form shapes suitable for different products. By means of the two modes, sterilization and virus killing can be efficiently conducted for a long time, and the risk of secondary contamination of germs and viruses is avoided.

Owner:慧智宇光电科技(珠海)有限公司

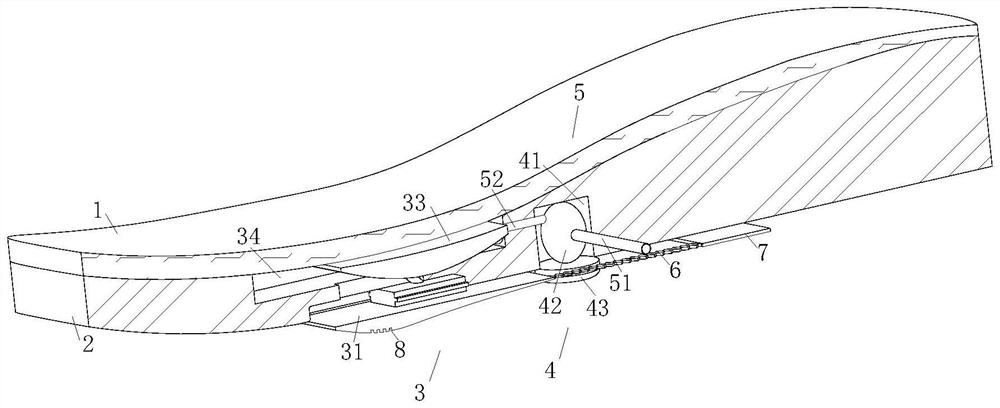

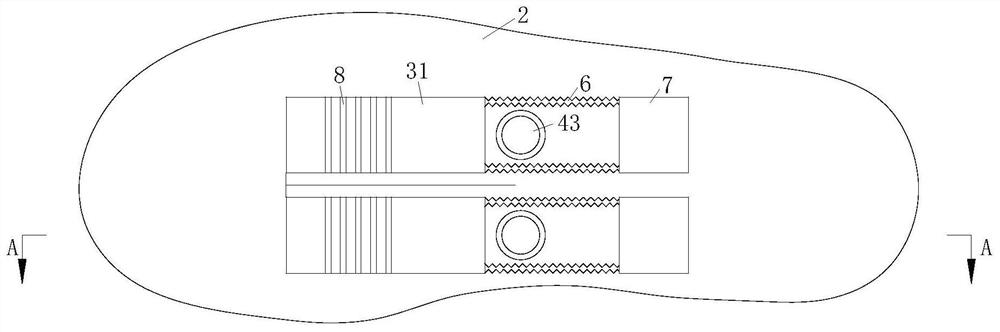

A polyurethane sole

The invention belongs to the technical field of shoe soles, specifically a polyurethane shoe sole, which includes an inner layer that can be in contact with the sole of the foot and a bottom layer that can be in contact with the ground; it includes a heating module, a shock-absorbing module and a breathable module; the heating module includes a sliding plate, Connecting rod, friction plate, No. 1 cavity and return spring; there are two No. 1 cavities at the front end of the bottom layer, and the No. 1 cavity is I-shaped; a friction plate is placed on the upper part of the No. 1 cavity, and the friction The upper end of the plate is in contact with the inner layer; the middle part of the No. 1 cavity is provided with a connecting rod, and the upper end of the connecting rod is fixedly connected with the lower end of the friction plate; the lower part of the No. The upper end of the part is fixedly connected with the lower end of the connecting rod; the upper part of the No. 1 cavity is fixedly connected with a return spring at the position towards the rear end, and the other end is fixedly connected with the friction plate; Problem with cold feet when walking.

Owner:JIANGSU YUREN GARMENT

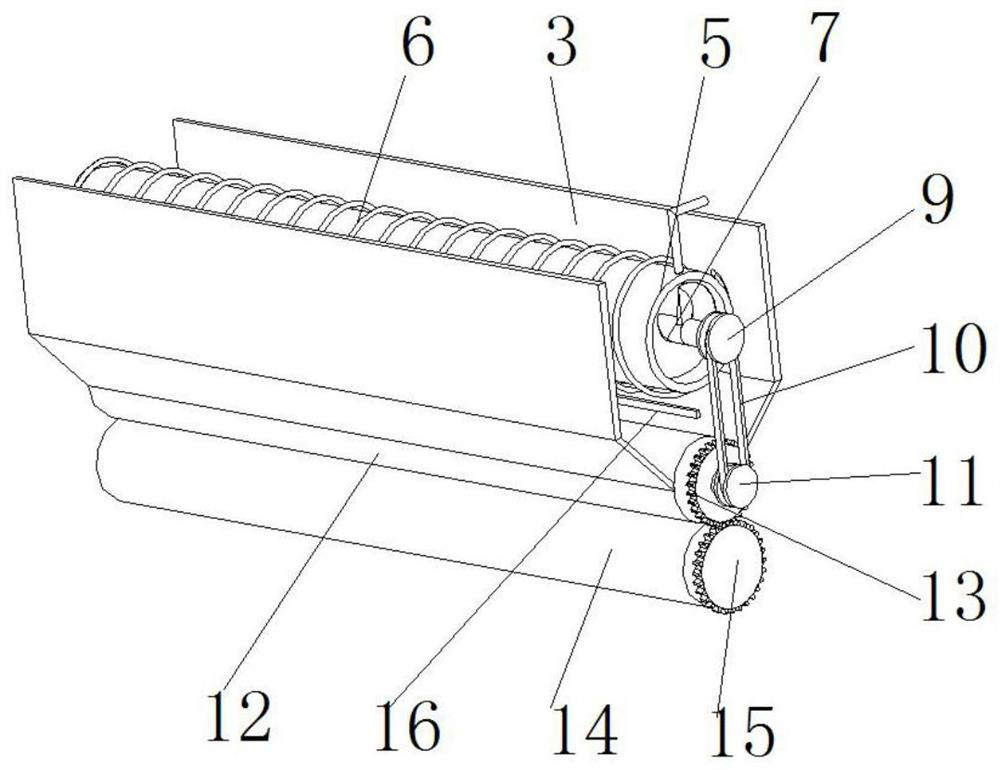

Cotton and Linen Cloth Drying Equipment

ActiveCN109506442BHeating fastImprove drying efficiencyDrying machines with progressive movementsDrying solid materialsProcess engineeringMaterials science

The invention discloses a cotton and linen drying equipment, which comprises a frame; a box body covered on the frame; a drying roller structure for contacting with wet cotton and linen; Stretching the cotton and linen fabric to open the holes in the cotton and linen fabric when drying the fabric; a heating structure for raising the temperature of the drying roller structure; a dehumidification structure that absorbs moisture in the oven, and the dehumidification structure absorbs the moisture The inner wall of the box is heated. The invention directly contacts the cloth by setting the structure of the drying roller, so when the cloth is dried, the temperature on the cloth can be quickly transferred to the cloth, so the cloth is heated quickly and the drying efficiency is high.

Owner:SHAOXING UNIVERSITY

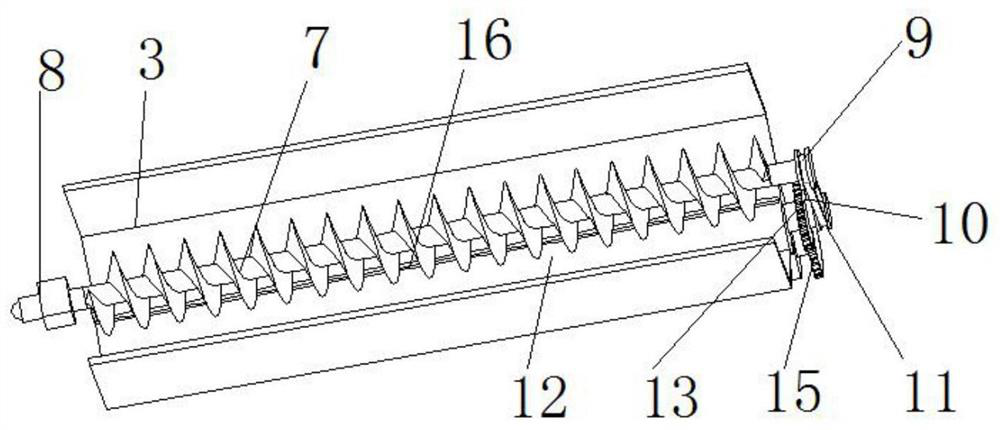

A low-temperature dyeing process suitable for vegetable dyes

ActiveCN113388987BReal time heatingImprove heating efficiencyLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsProcess engineeringMechanical engineering

The invention discloses a low-temperature dyeing process suitable for plant dyes, and relates to the field of low-temperature dyeing of dyes. The low-temperature dyeing process of plant dyes is implemented through a dyeing mechanism. The dyeing mechanism includes a box body, and a stopper is fixed on the inner wall of the box board, and the baffle divides the box into a dyeing room and a cooling room on one side of the dyeing room. The invention can heat the dye flowing into the metal tube through the electromagnetic coil, so that the dye can be heated in real time, so that the heating efficiency is higher and the heating is more uniform, and the temperature is more convenient for stable control. At the same time, the first servo motor drives the helical blade to rotate , can pressurize and mix the dye evenly, so that the additives in the dye can react more evenly; through the first gear and the second gear, the second roller and the first roller rotate in opposite directions, which can make the fabric in the second The supporting roller and the first supporting roller move directly, which makes the dyeing more uniform and more efficient.

Owner:SUZHOU SENCHUANG TEXTILE TECH CO LTD

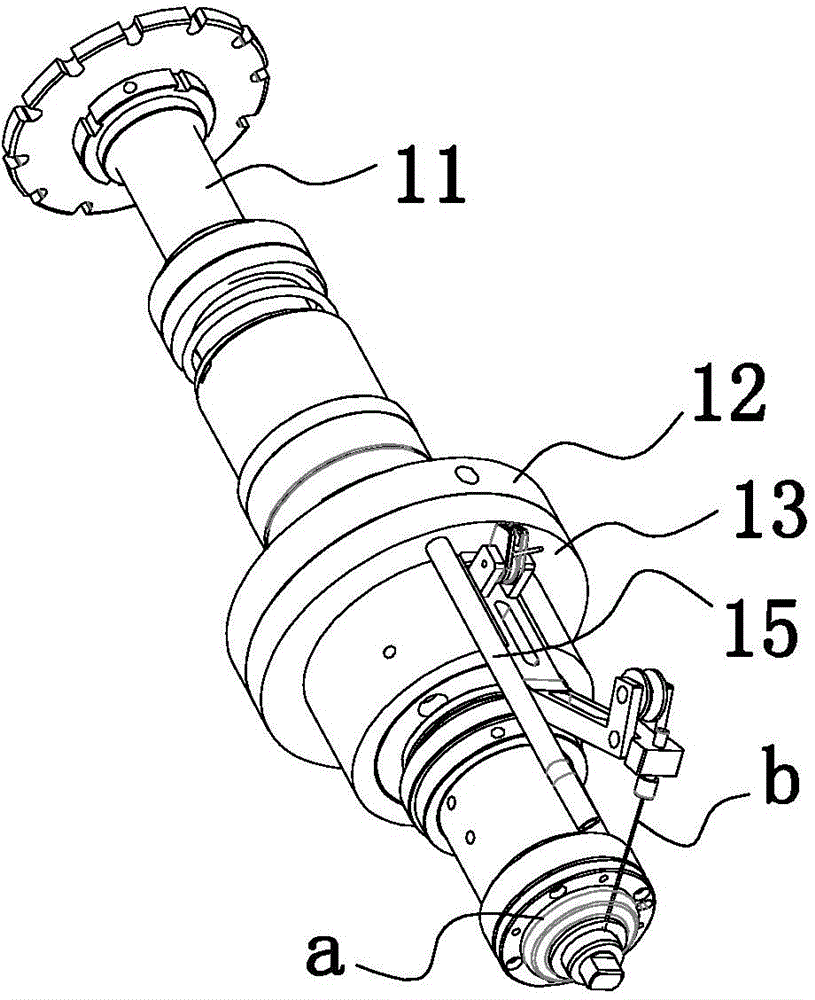

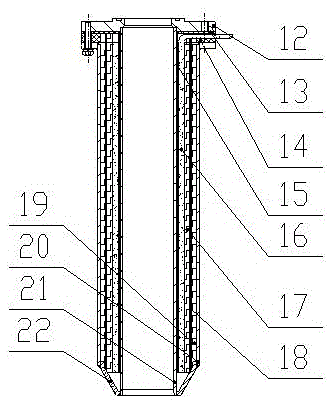

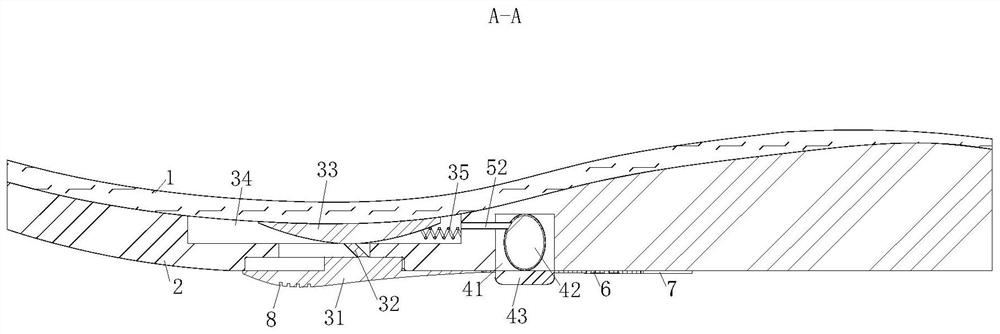

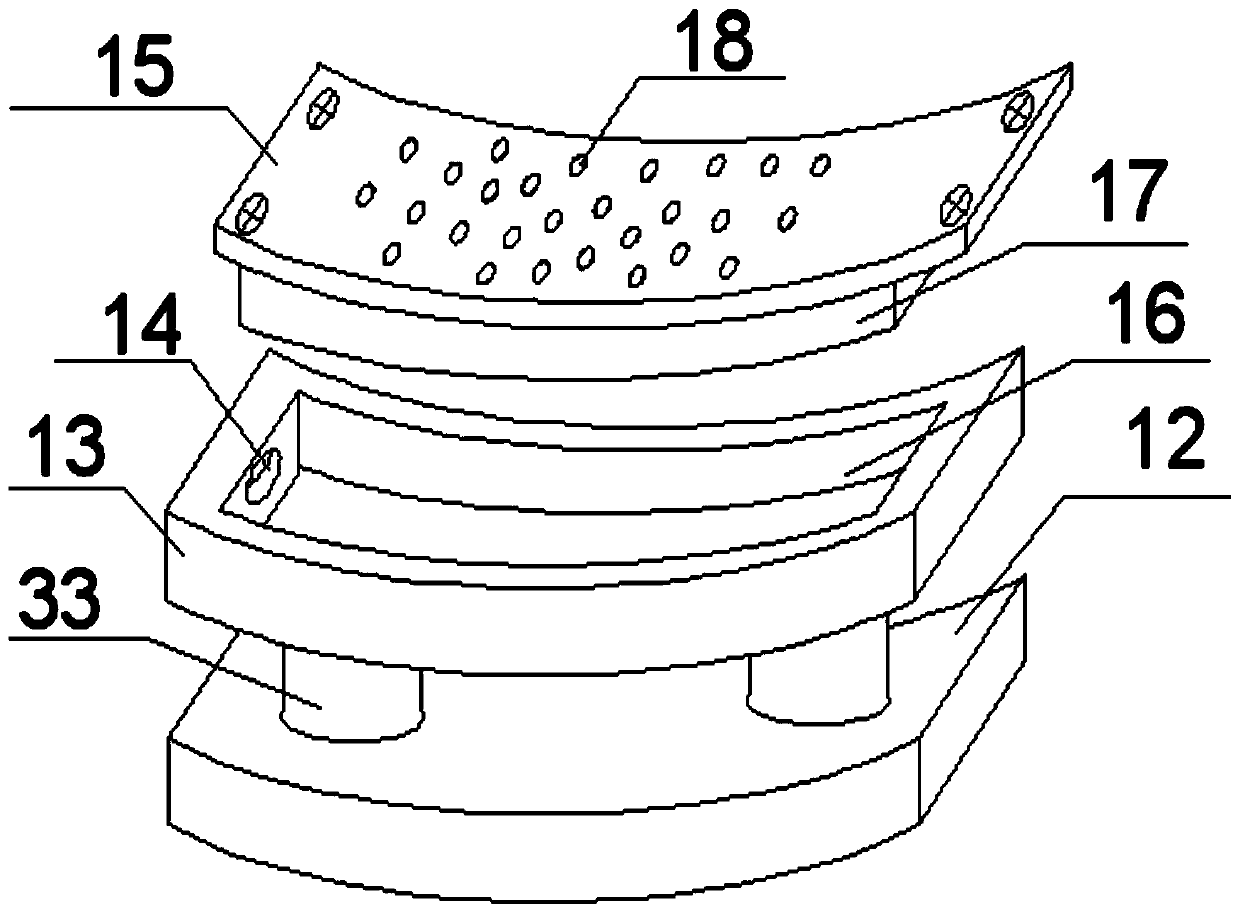

Spinning forming device for head cover of seeker and forming method thereof

PendingCN109622714AReal time heatingImprove processing efficiencyShaping toolsMetal-working feeding devicesBusbarEngineering

The invention discloses a spinning forming device for a head cover of a seeker and a forming method thereof. The spinning forming device for the head cover of the seeker comprises a mold core clampedon a spinning machine; the profile of the mold core is coincident with the inner profile of the head cover of the seeker; a workblank to be machined is placed concentrically on the mold core, and theother side of the workblank is tightly ejected through a tail ejector; the outer periphery of the workblank is provided with an electromagnetic induction coil and a rotating wheel, and the electromagnetic induction coil is used for heating the workblank; and when the predetermined temperature is reached, the rotating wheel and the electromagnetic induction coil are separately fed from both sides in the direction of a busbar, and are formed under the pressing action of the rotating wheel. In the forming process, the head cover of the seeker is obtained by spinning forming aiming at different wall thicknesses of parts formed by a thin-walled curved busbar combined with a cylindrical shaped portion, the volume of the cylindrical shaped portion is calculated by the product of the wall thickness and the cross-sectional area, and a curved busbar portion is obtained by the law of positive rotation; and the rotating wheel and the electromagnetic induction coil are separately fed from both sides in the busbar direction of the mold core, so that the workblank is machined point by point into a thin-walled curved busbar rotating body. The number of spinning times of the spinning forming deviceis small, the implementation is simple, and the machining precision is high.

Owner:西安深瞳智控技术有限公司

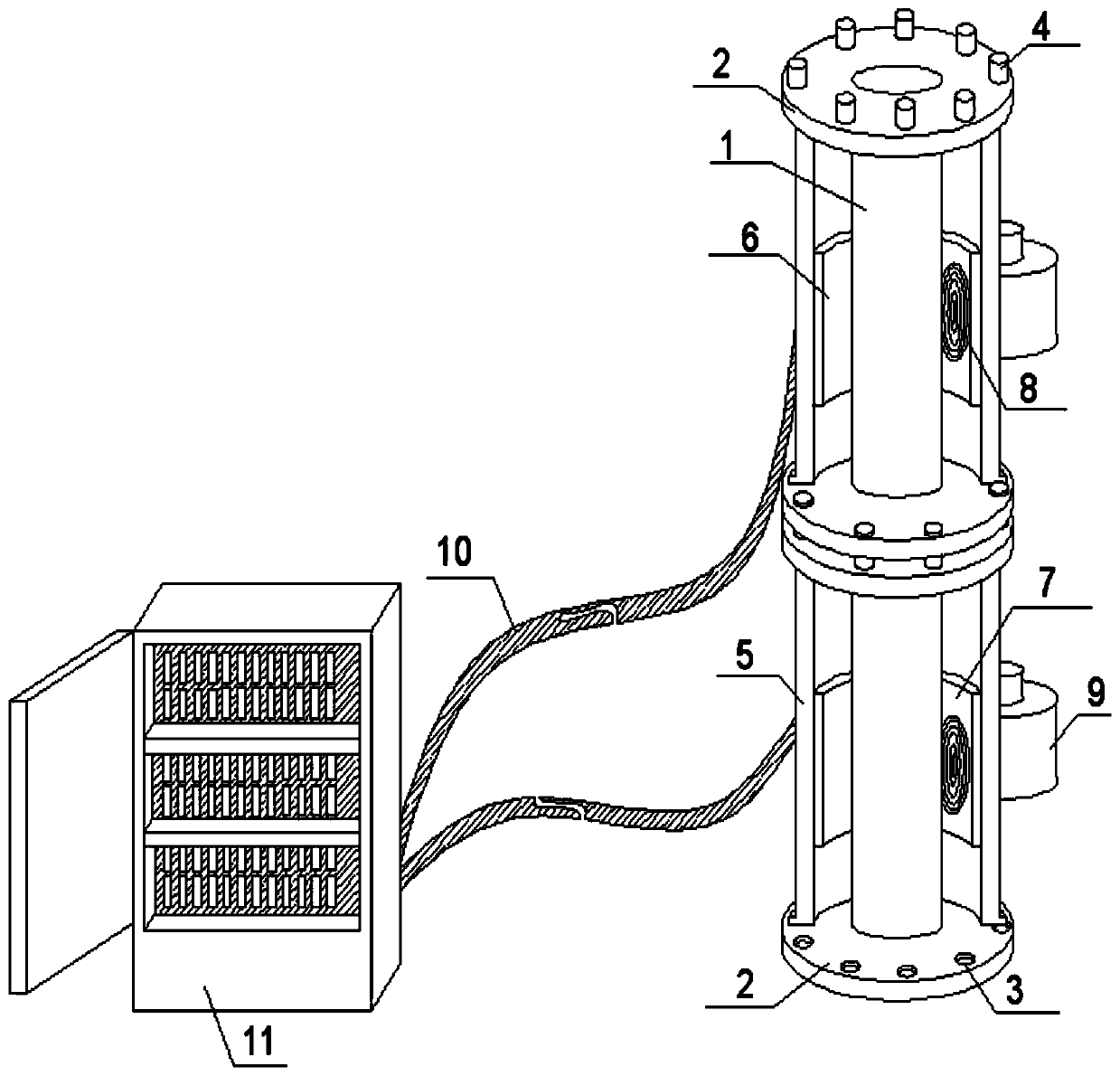

Liquefied natural gas gasification assembly device

ActiveCN108386720BMaintain a constant temperatureImprove combustion efficiencyPipe heating/coolingPipeline systemsProcess engineeringHeating system

The invention discloses a liquefied natural gas gasification assembly device which comprises a gas pipeline. Connecting discs are arranged at the two ends of the gas pipeline. Bolt holes are formed inthe connecting discs. Bolt holes are provided with studs. A heating pipeline is arranged on the periphery of the gas pipeline. A heating pipeline is fixed between the two connecting discs. The innerwall of the heating pipeline is provided with a temperature induction module and a heating module. A relay is arranged on the side wall of the heating pipeline. The heating module is connected with the relay. The heating pipeline is connected with a PLC control cabinet through a wire. The relay is connected with the PLC control cabinet through a wire. By means of the liquefied natural gas gasification assembly device, real-time heating can be conducted on natural gas, it is ensured that a constant temperature is kept on the natural gas in the whole transporting process, influences of the external temperature do not exist, the combustion efficiency of the natural gas is improved, and a natural gas heating system can be controlled in a remote manner.

Owner:芜湖中燃城市燃气发展有限公司

A nanofiltration membrane regeneration method

ActiveCN106268341BAchieve regenerationGood water solubilitySemi-permeable membranesGeneral water supply conservationOxalateViscose

The invention discloses a nanofiltration membrane regenerating method, relating to the field of viscose recovery. The method mainly comprises the steps of circularly cleaning demineralized water to adjust the demineralized water to be neutral, circularly cleaning an oxalic acid solution to remove hemicelluloses and impurities, and cleaning the demineralized water to adjust the demineralized water to be neutral again. By utilizing the washing-acid pickling-washing process, hemicelluloses accumulated in nanofiltration membrane holes can be effectively removed, divalent ions such as calcium, magnesium, ferrum and silicon form a complex to deposit the nanofiltration membrane subjected to secondary pollution in the cleaning process, so that the cleaned nanofiltration membrane achieves more than 93% of a rated value, and the regeneration of the nanofiltration membrane can be realized.

Owner:YIBIN GRACE +1

Tea seedling grafting and seedling raising device

PendingCN114532112AReal time heatingGraftingClimate change adaptationEngineeringEnvironmental geology

The invention is suitable for the technical field of grafting seedling raising equipment, and provides a tea seedling grafting seedling raising device which comprises a device body and a placing mechanism located in the device body, and further comprises a spraying heat preservation mechanism movably connected with the device body and used for conducting atomization spraying and heat preservation on tea seedlings, the spraying heat preservation mechanism comprises a transmission assembly, a driving part A, a rotating shaft B, a heat preservation assembly and a spraying assembly, the driving part A and the rotating shaft B are both in transmission connection with the transmission assembly, and the heat preservation assembly is in transmission connection with the spraying assembly through the transmission assembly. The device is reasonable in structure, and tea seedlings can be subjected to constant-temperature protection and atomization spraying.

Owner:ANHUI DECHANG OIL & TEA PROFESSIONAL COOP

A high-end self-heating lunch box

ActiveCN112401670BReal time heatingEasy to operateSteam cooking vesselsWarming devicesWater storageThermodynamics

The disclosure of the present invention relates to the technical field of food heating, specifically a high-end self-heating bento box, including a box body. The box body is sequentially provided with a connecting frame, an inner tank and a reaction chamber. Both sides of the reaction chamber are symmetrically provided with heat source grooves. The heat source tanks are equipped with heating packs, the center of the reaction chamber is vertically provided with the first rebound tank, and the two sides of the first rebound tank are symmetrically provided with water storage boxes between the two heat source tanks. The installed water belt and heating pack can heat the food in real time in different places of use. Regardless of the scene and time, the use range is wider. The push-type start device is easy to operate, and the reaction between the heat source and the water is generated. The steam is preheated at the bottom of the liner first, and the rest of the steam goes up to the steam chamber through the steam channel, and is diverted to the tableware disinfection area and the food heating area at the lower end. The connecting frame and the liner can place heated food, and the space is larger.

Owner:武汉中山舰旅游开发有限公司

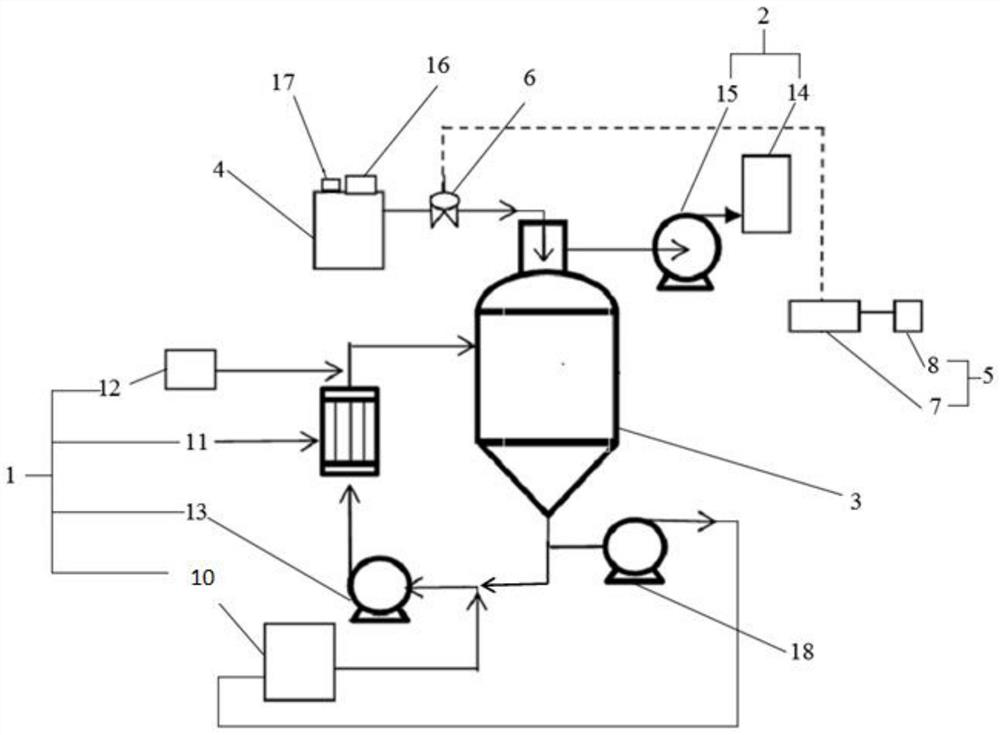

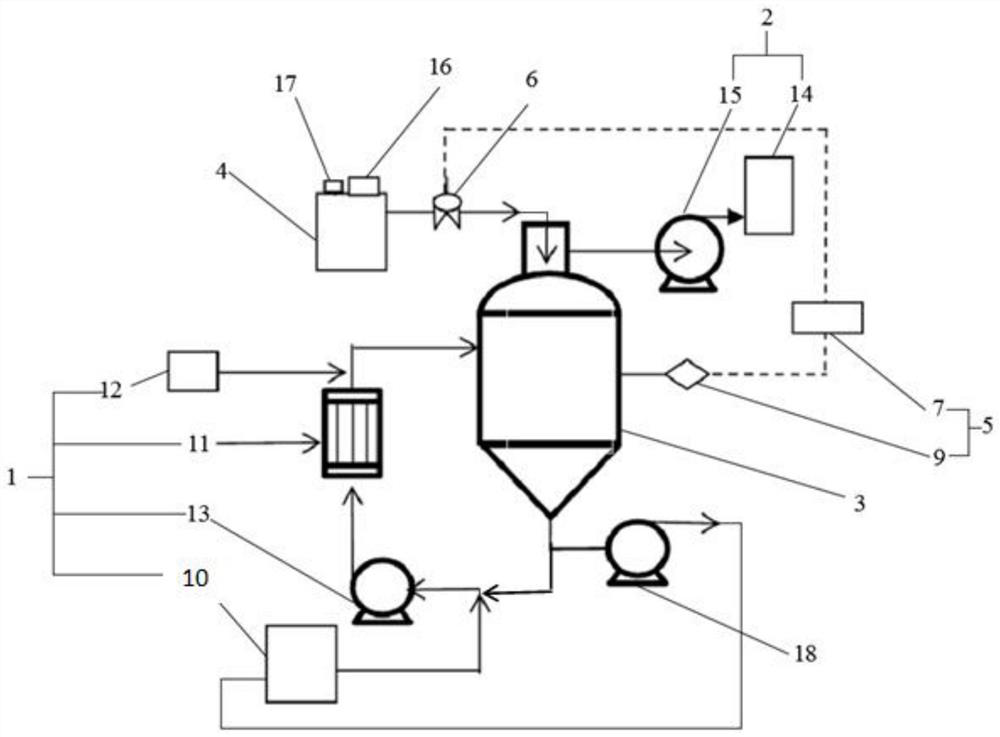

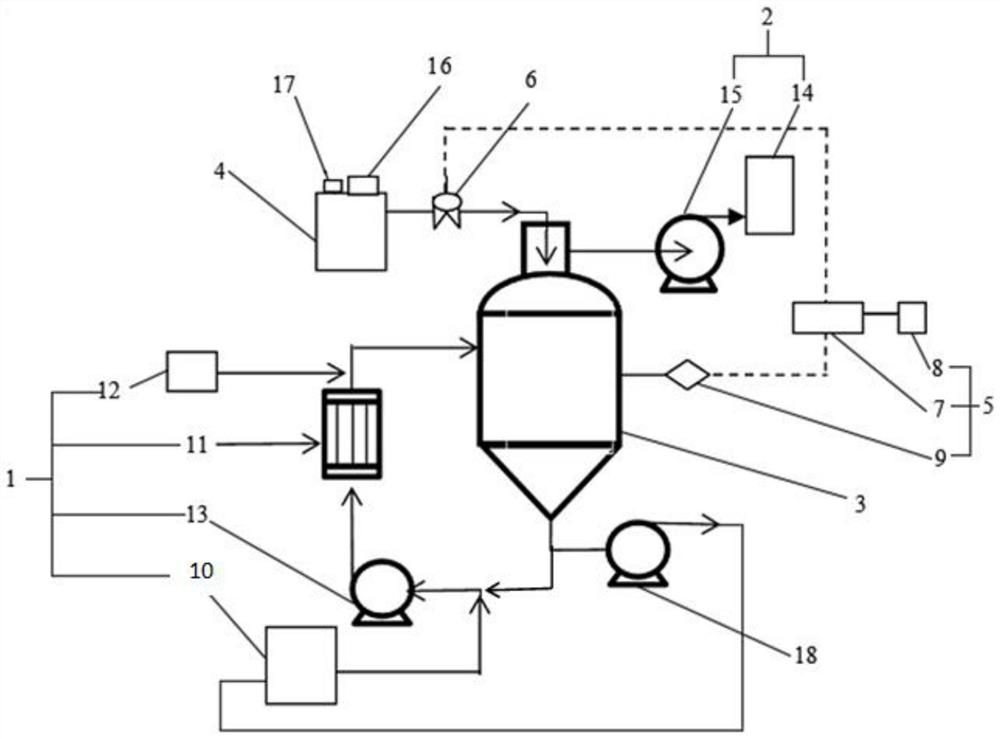

A chlorine dioxide generating system

ActiveCN107954396BQuick breakdownHas strong oxidizing propertiesChlorine dioxideChlorine dioxideProcess engineering

The invention provides a chlorine dioxide generation system which comprises a reactant input end, a product output end, a generator and a defoaming agent tank, wherein the reactant input end, the generator and the product output end are sequentially communicated, and the defoaming agent tank is communicated with the generator. According to the chlorine dioxide generation system disclosed by the invention, foams wrapping a lot of chlorine dioxide in the reactor can be quickly defoamed, so that chlorine dioxide gas can be quickly released, a chlorine dioxide decomposition rate in the generator is effectively reduced, too much energy is prevented from being generated, and equipment is prevented from being damaged; furthermore, a production efficiency is improved, service life of the whole system is prolonged, production cost is reduced, and more environmental friendliness to the environment is achieved.

Owner:HAINAN JINHAI PULP & PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com