A chlorine dioxide generating system

A generation system, chlorine dioxide technology, applied in the direction of chlorine dioxide, chlorine oxide, etc., can solve the problems of production equipment and facilities hazards, increased manufacturing costs, unstable chemical properties, etc., to reduce costs, save costs, and resist oxidation sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

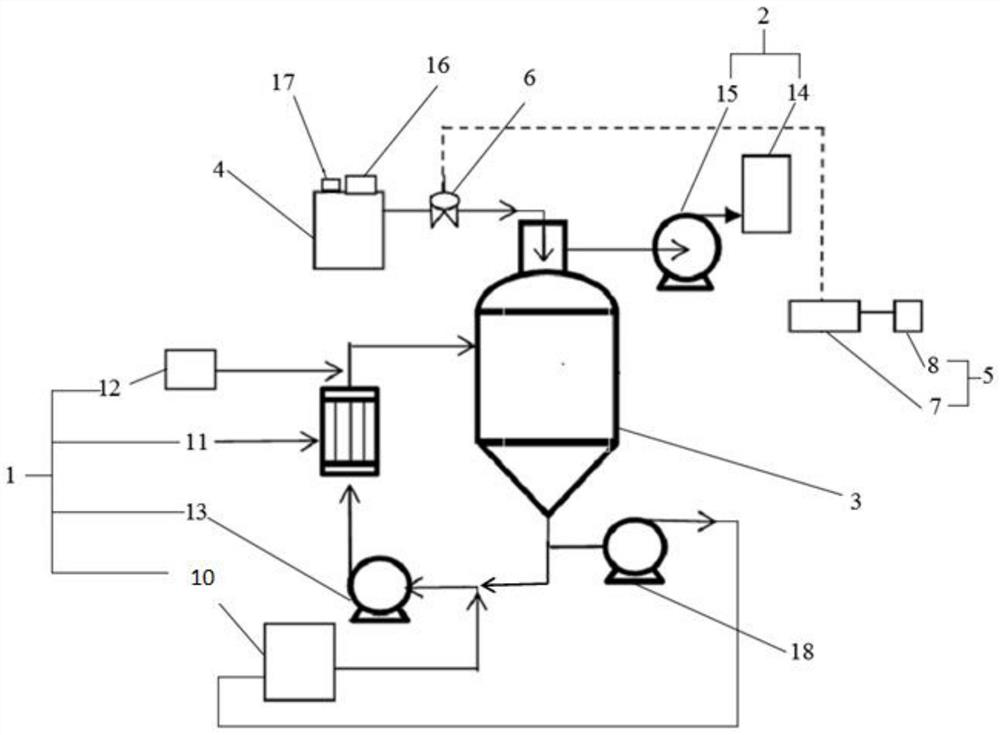

Method used

Image

Examples

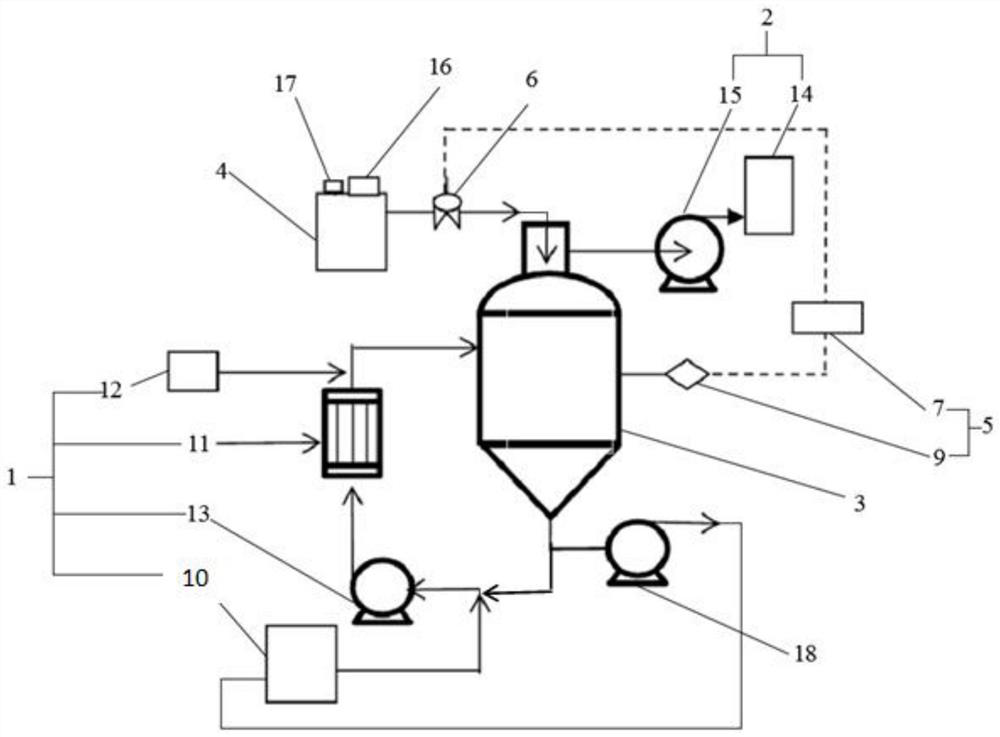

Embodiment 2

[0024] see figure 2 , the difference between this embodiment and embodiment 1 is that the control device 5 includes a controller 7 and a liquid level gauge 9, the controller 7 is connected with the liquid level gauge 9 and the automatic regulating valve 6 respectively, and the liquid level gauge 9 is installed On the side wall of the reactor 3 at a certain height, when a certain amount of foam is generated in the reactor 3, the liquid level of the solution rises and touches the liquid level gauge 9, the liquid level gauge 9 transmits the signal to the controller 7, and the controller 7 and Control the opening of the automatic regulating valve 6, so that the tributyl phosphate solution immediately enters the inside of the generator 3 for defoaming. This setting makes the defoaming more automatic, which can effectively avoid excessive decomposition of chlorine dioxide inside the generator 3 in time, and avoid damage to equipment caused by excessive energy in time.

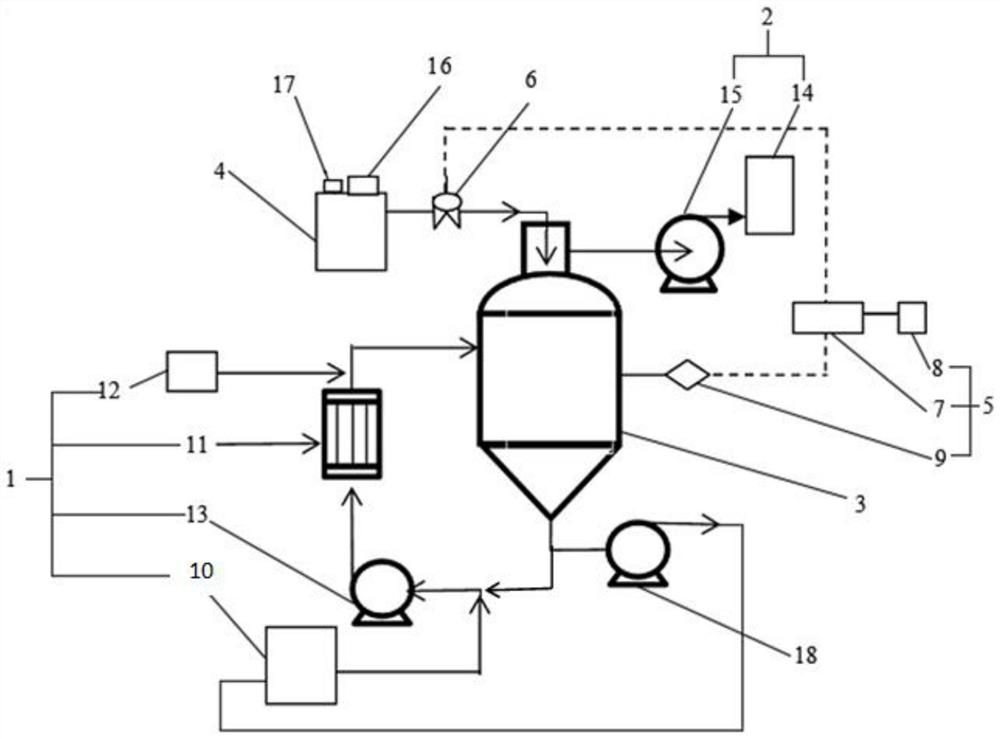

Embodiment 3

[0026] see image 3 , The difference between the embodiment and the embodiment 1 is that the control device 5 includes a controller 7, a liquid level gauge 9 and a timer 8, and the controller 7 is connected with the liquid level gauge 9, the timer 8 and the automatic regulating valve 6 respectively. connect. On the one hand, it is possible to set the interval target time for defoaming, and at the same time, defoaming can be carried out according to the liquid level inside the reactor 3. The combination of the two makes the defoaming more thorough. System reliability.

[0027] According to statistics, using the chlorine dioxide generation system of the present invention, the decomposition inside the generator 3 is reduced from 10 times per month to once per month, which can save 45,000 yuan in manufacturing costs per month, effectively protects the equipment, and prolongs the life of the generator. the service life of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com