Heating system and heating method for dual-head hollow coil winding device

An air-core coil and heating system technology, applied in coil manufacturing and other directions, can solve the problems of short service life of the winding jig, inability to start the winding operation immediately, and short service life of the winding jig, so as to improve the processing quality and Stability in later use, shortened heating time, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

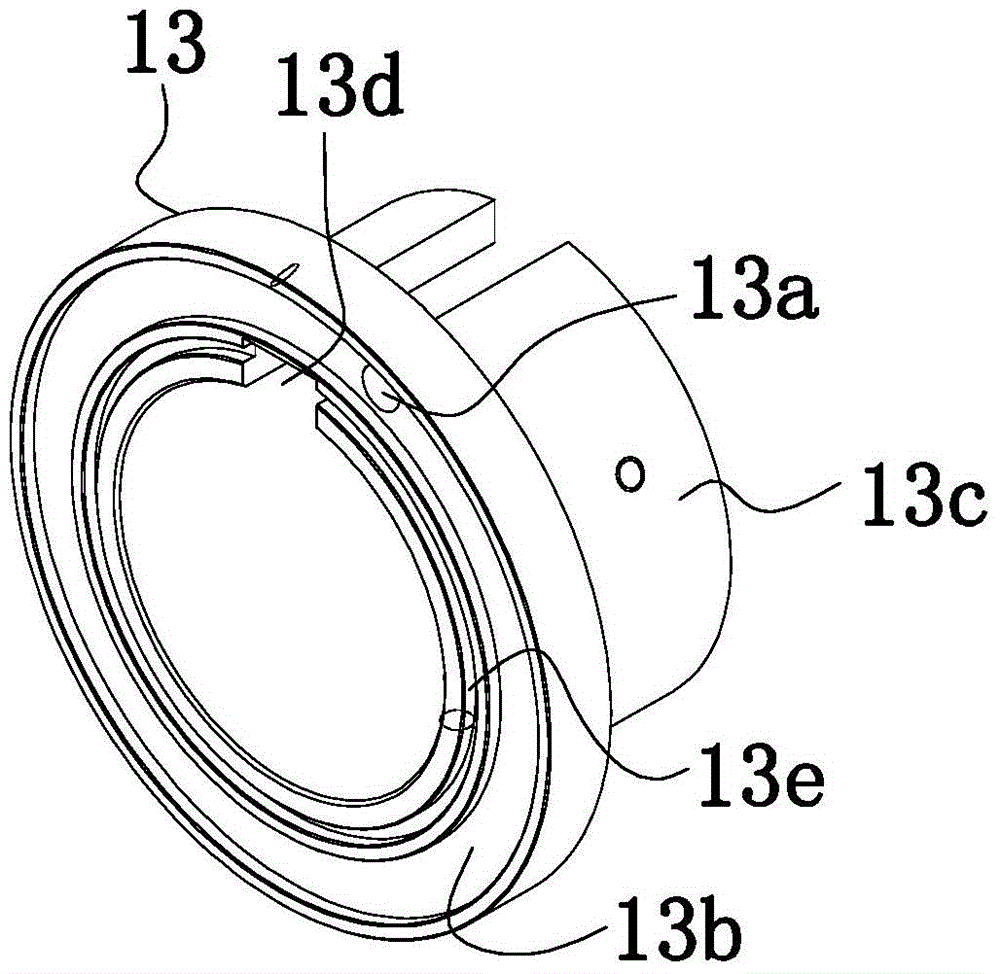

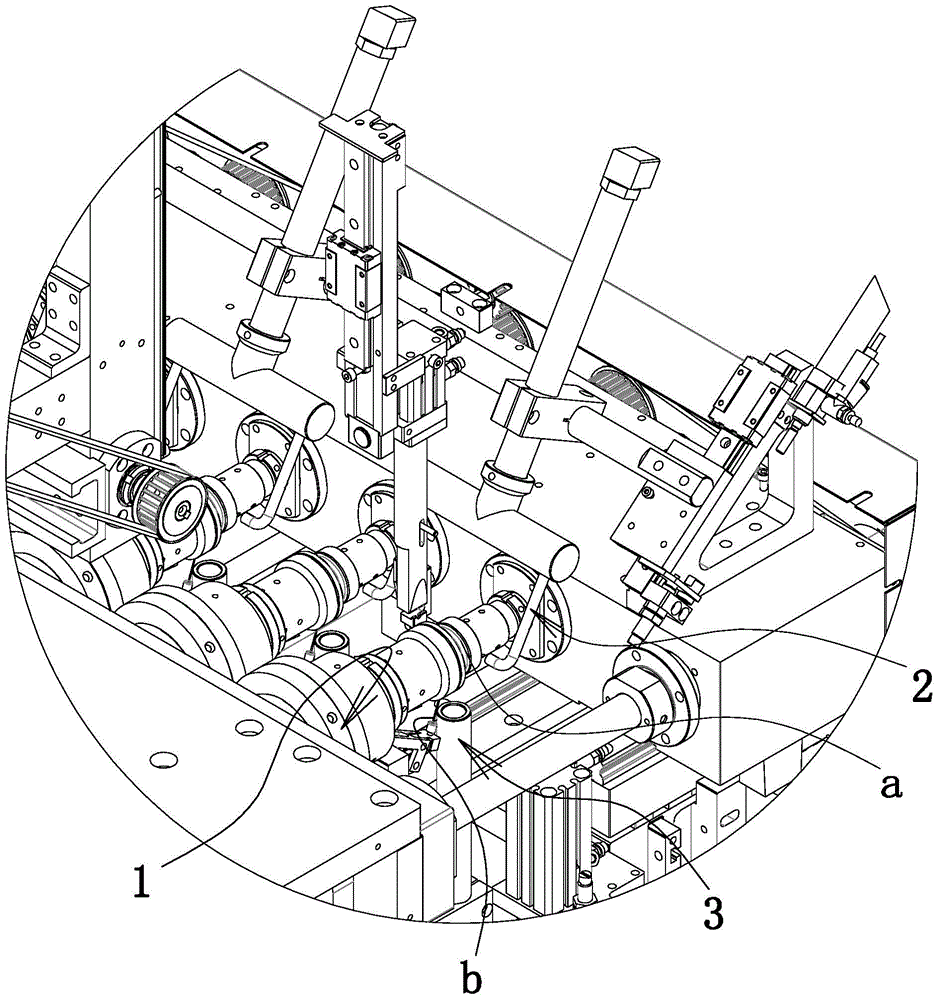

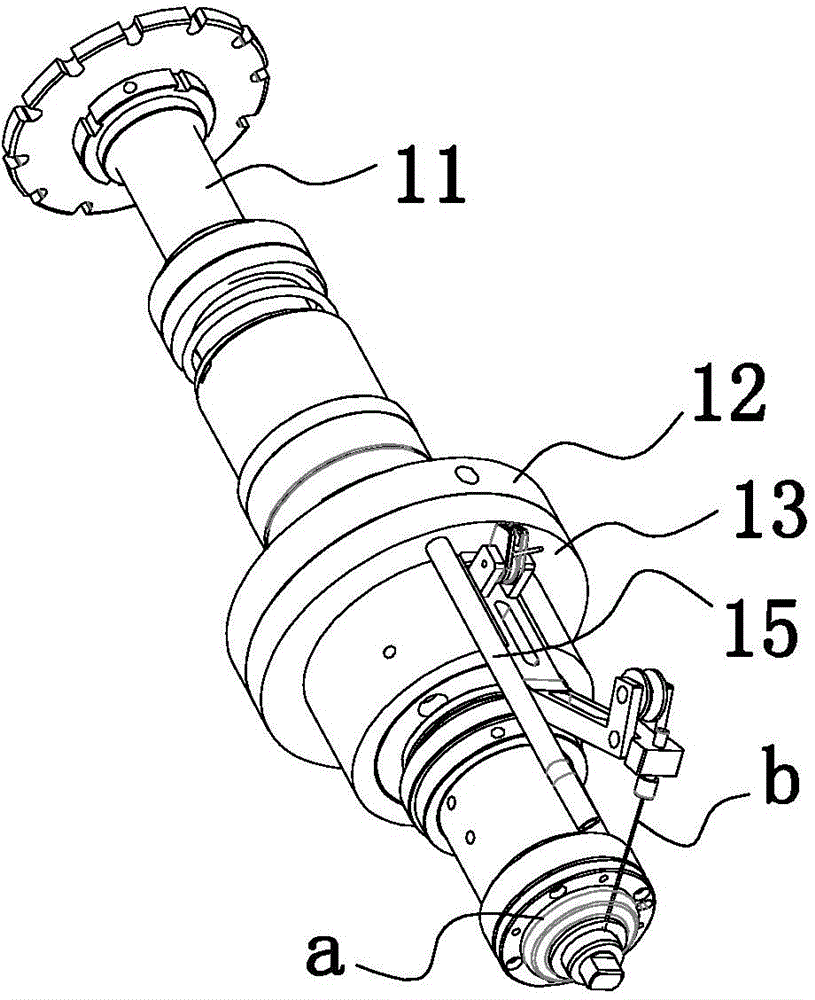

[0033] Such as Figure 1-7 As shown, the heating system of the double-headed hollow coil winding equipment, the winding machine includes at least one winding jig a, the heating system includes when one end of the coiled wire b rotates along the circumferential direction of the winding jig a so that A rotary preheating mechanism 1 capable of real-time heating of the coiled wire b continuously coiled on the winding jig a when coiled on the winding jig a, specifically, the rotary preheating mechanism 1 of this embodiment The mechanism 1 includes a rear annular end cap 12 sleeved on the main shaft 11 and connected to the main shaft 11 in rotation, and a front annular end cap 13 that is circumferentially movable and sealingly connected with the rear annular end cap 12 is also sleeved on the main shaft 11. An annular air groove 14 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com