Liquefied natural gas gasification assembly device

A liquefied natural gas and assembly technology, which is applied in gas/liquid distribution and storage, pipeline system, pipeline heating/cooling, etc., can solve the problems of reducing natural gas, reducing natural gas combustion efficiency, increasing user costs, etc., and achieves the goal of improving combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

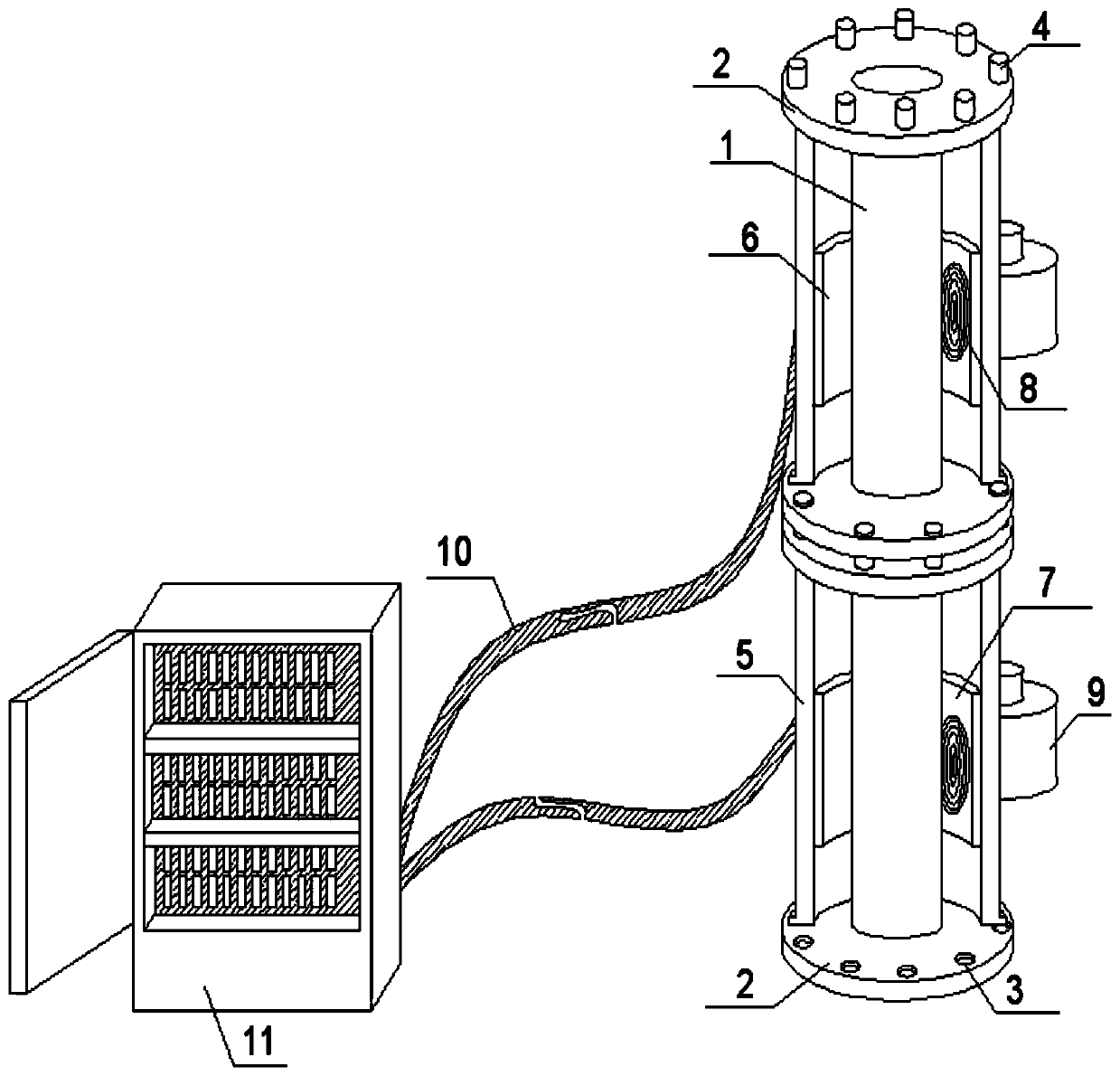

[0025] The temperature sensing module 6 and the relay 9 are controlled by the PLC control cabinet 11 , and the relay 9 controls the heating module 7 .

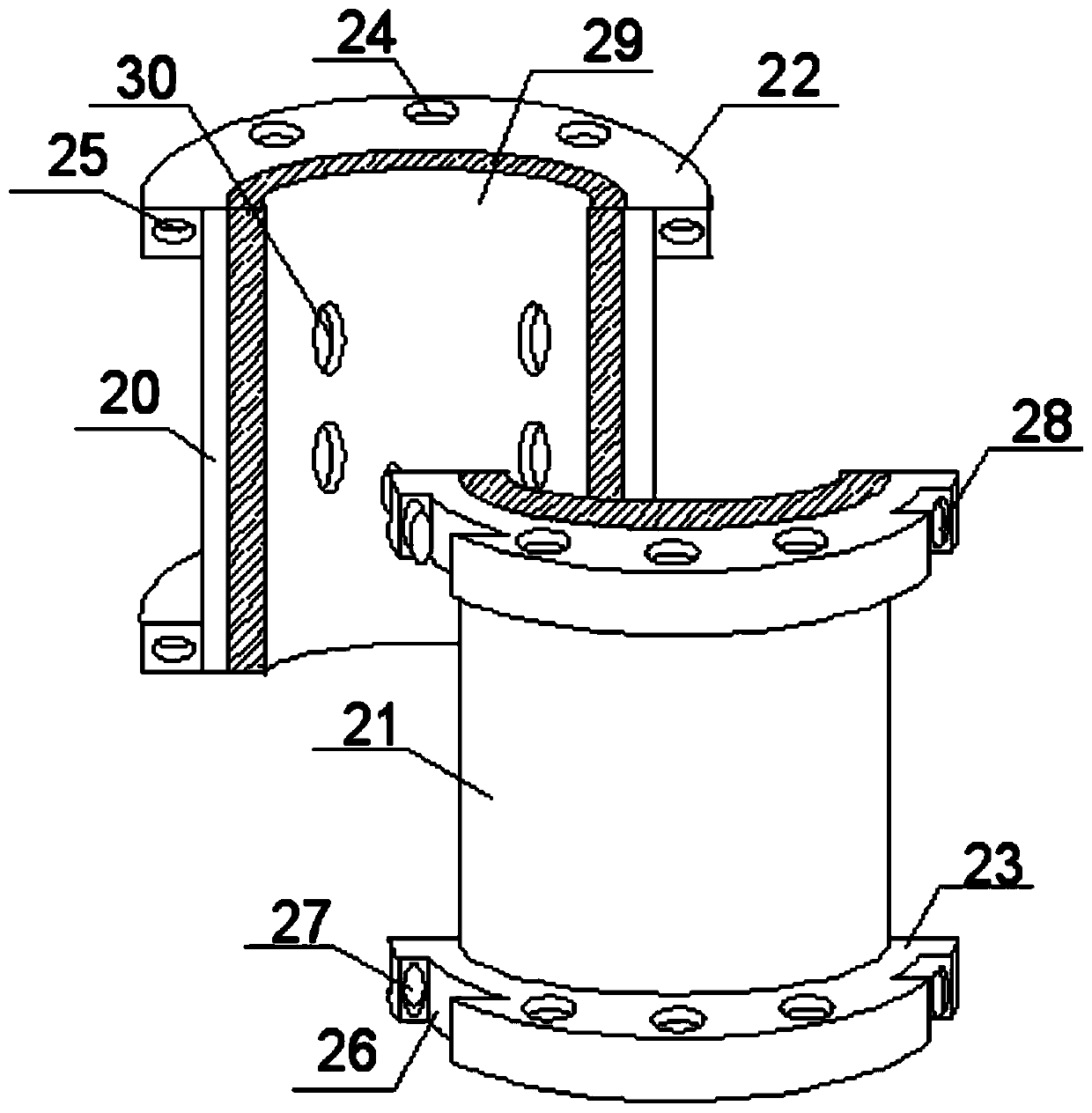

[0026] The heating pipeline 5 includes a left half-pipe 20 and a right half-pipe 21, the upper surface and the outer edge of the lower surface of the left half-pipe 20 are respectively provided with a left fixing ring 22, and the upper surface and the outer edge of the lower surface of the right half-pipe 21 are A right fixing ring 23 is provided respectively, and a plurality of threaded holes 24 are respectively provided on the surfaces of the left fixing ring 22 and the right fixing ring 23 , and the threaded holes 24 correspond to the bolt holes 3 .

[0027] The type of the left half-pipe 20 is consistent with that of the right half-pipe 21 , and the type of the left fixed ring 22 is consistent with that of the right fixed ring 23 .

[0028] The upper and lower side walls of the left fixed ring 22 are respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com