IGBT device testing device and method

A technology of testing device and testing method, which is applied in the field of power electronics, can solve problems such as the inability to understand the degradation process of failed devices and the changing rules of other parameters, and achieve the effect of improving the high-temperature and high-humidity withstand voltage reliability of IGBT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

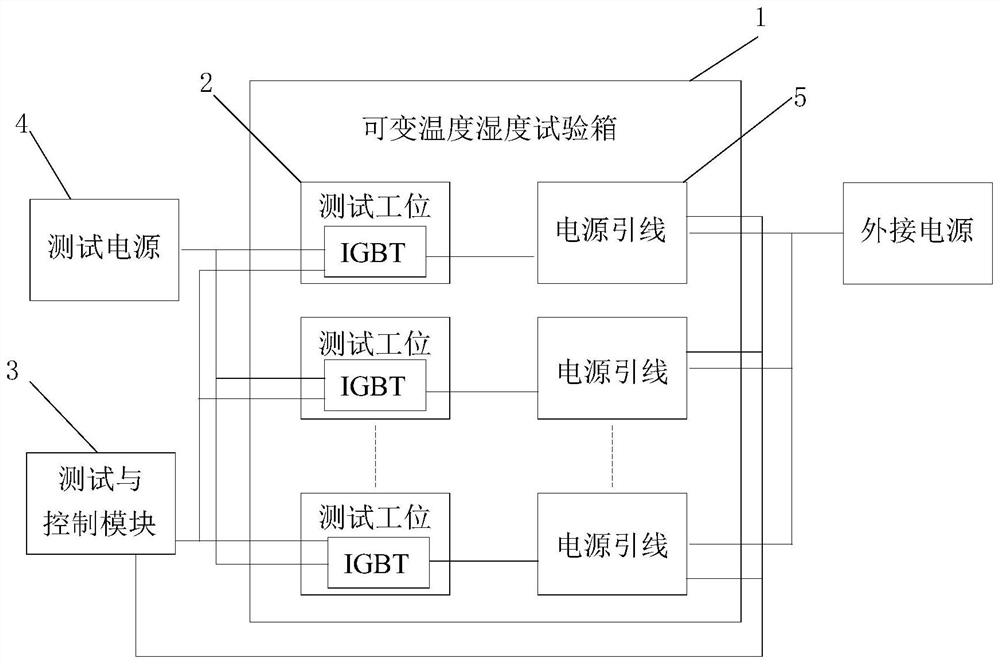

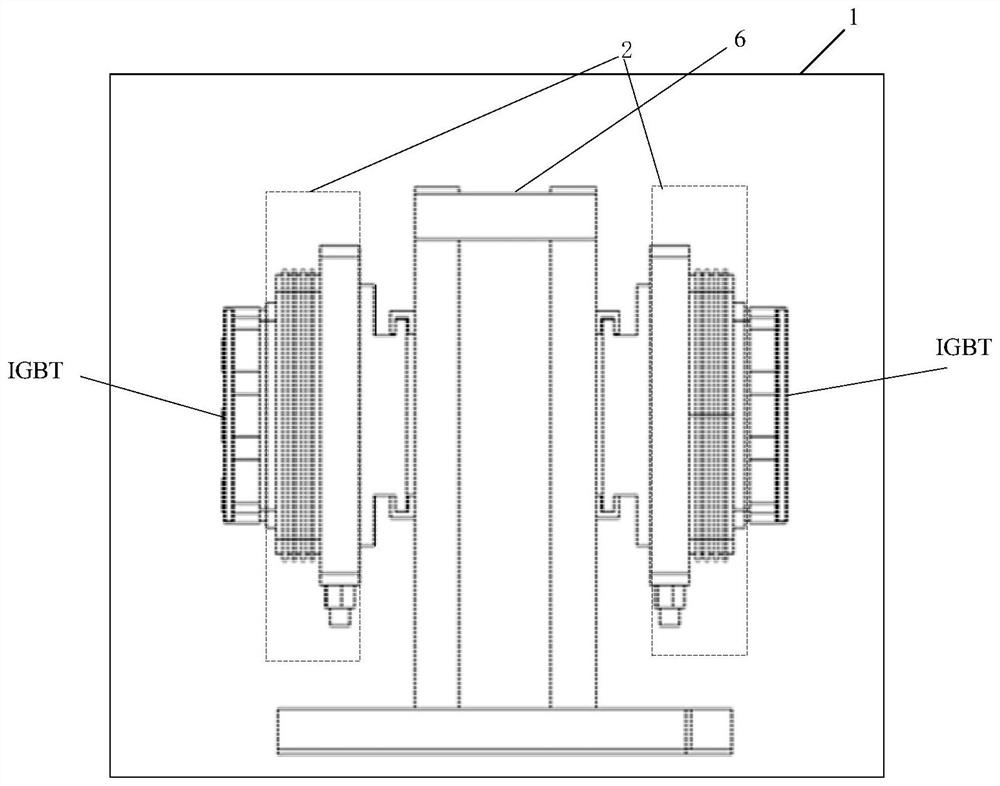

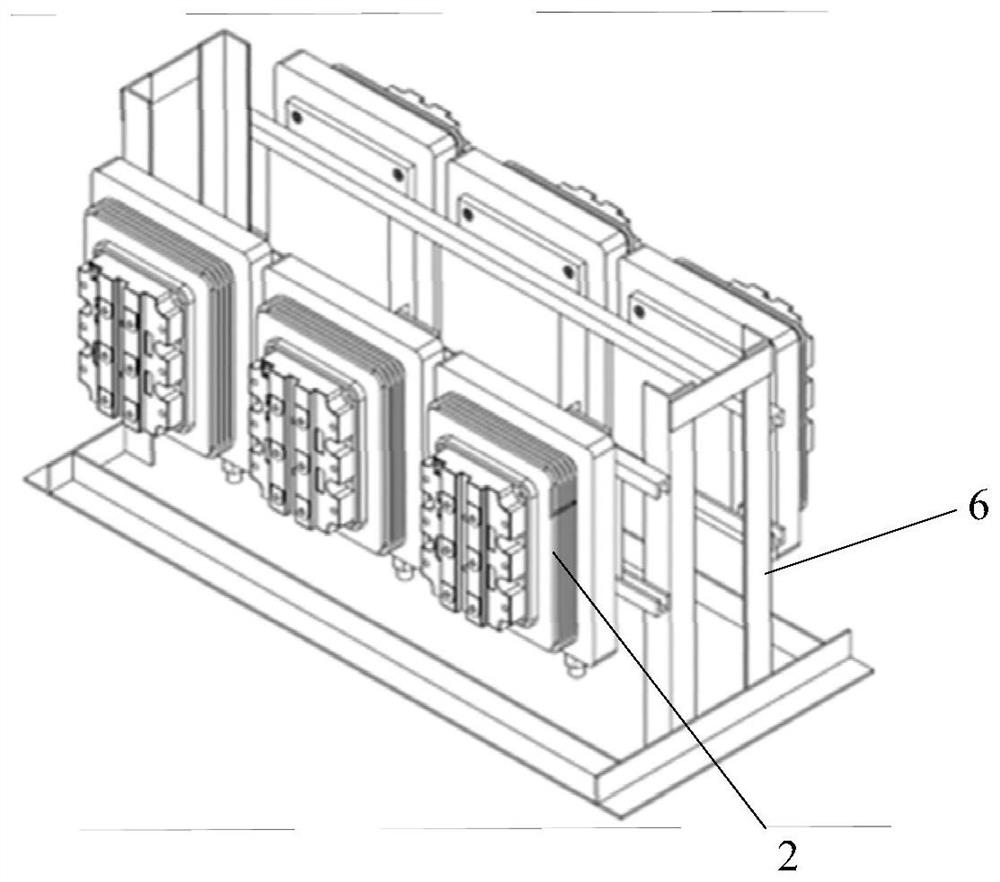

[0041] The embodiment of the present invention provides an IGBT device testing device, which is applied to occasions where it is necessary to analyze the degradation characteristics of the IGBT under high temperature, high humidity and high pressure blocking, such as figure 1 As shown, it includes: a variable temperature and humidity test chamber 1, a plurality of test stations 2, a test and control module 3, a test power source 4 and a plurality of power lead wires 5.

[0042] Since the high-temperature, high-humidity and high-voltage resistance tests of the IGBT are two independent tests in the prior art, and because it is impossible to test the degradation characteristic process and other parameter change rules of the IGBT under high-temperature, high-humidity, and high-voltage blocking, this paper In the embodiment of the invention, a variable temperature and humidity test chamber is used to control the temperature and humidity of the test environment, and all test stations...

Embodiment 2

[0060] An embodiment of the present invention provides a method for testing an IGBT device. The IGBT device is tested based on the IGBT device testing device in Embodiment 1, such as Figure 10 As shown, the IGBT device test methods include:

[0061] Step S11: Acquiring preset test temperature and preset test relative humidity.

[0062] Step S12: After controlling the temperature and humidity in the variable temperature and humidity test chamber to reach the preset test temperature and preset test relative humidity, the IGBT is periodically tested.

[0063] Step S13: After the periodic test of each IGBT is completed, record the number of periodic tests of each IGBT, and judge whether the number of periodic tests of each IGBT reaches the preset number of tests. When the number of periodic tests of the IGBT does not reach the preset number of tests, Return to the step of periodically testing the IGBT until the number of periodic tests of the IGBT reaches the preset number of te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com