Phase-change type heat storage device with built-in water tank

A heat storage device and water tank technology, applied in the field of heat storage, can solve problems such as damage to solder joints, large size, and installation difficulties, and achieve the effects of satisfying heating and hot water needs, stable phase transition process, and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

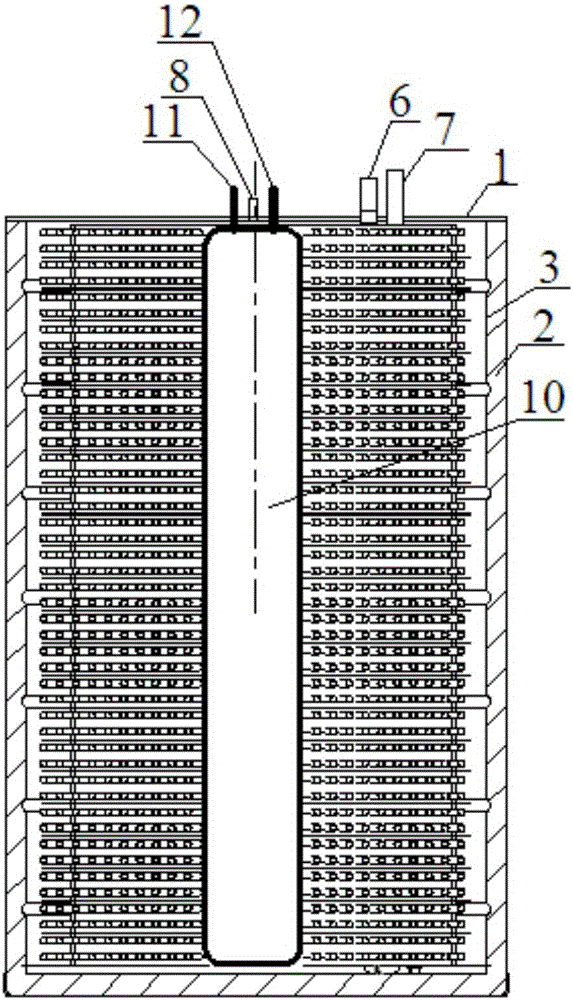

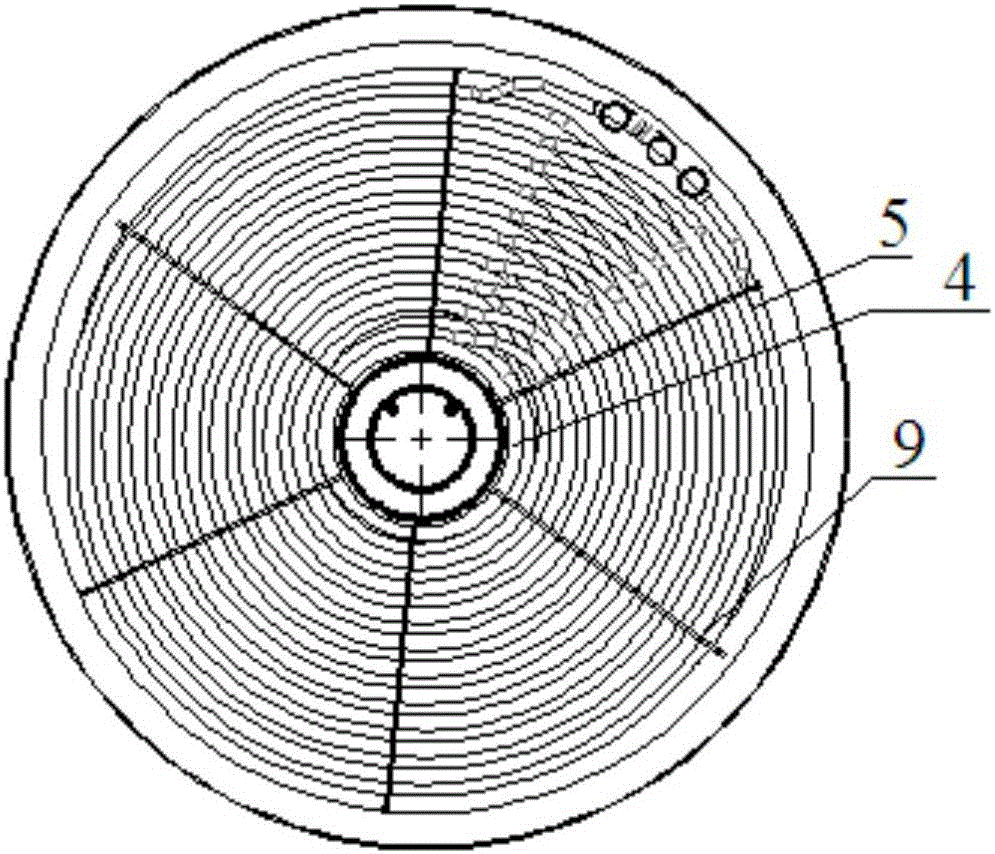

[0027] A phase-change heat storage device with a built-in water tank, such as figure 1 , figure 2 As shown, the outer shell 1 is included, the inner tank 3 is set in the outer shell 1, the insulation layer 2 is set between the inner tank 3 and the outer shell 1, the inner tank 3 is filled with a phase change material 4, and a heat exchange plate is embedded in the phase change material 4 The pipe 5 and the inlet and outlet of the heat exchange coil 5 extend to the outside of the inner tank 3, and are respectively connected to the main inlet pipe 6 and the main outlet pipe 7 by welding, and the main inlet pipe 6 and the main outlet pipe 7 are connected to the external heating pipe. System connection, the external system can provide stable and continuous heating or cooling. A built-in water tank 10 is arranged inside the liner 3, one end of the built-in water tank 10 is a cold water inlet pipe 11 for connecting tap water supply, the other end is a hot water outlet pipe 12 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com