Oil viscosity detection device detection chamber

A detection device and detection chamber technology, applied in the field of detection chambers, can solve problems such as easy adhesion and high viscosity of oil storage, and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in combination with specific embodiments.

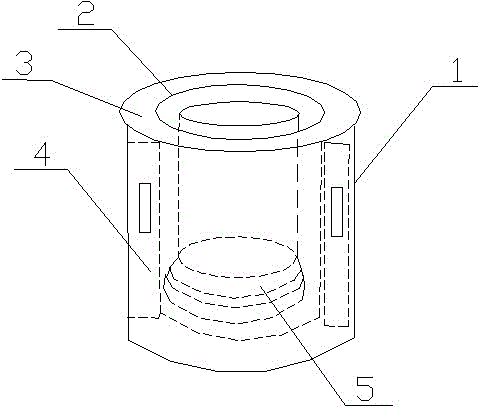

[0009] see figure 1 , a detection chamber for an oil viscosity detection device, including a detection chamber body, the detection chamber body includes a cylindrical outer shell 1 and an inner shell 2, the inner shell 2 is sleeved in the outer shell 1 and forms an annular cavity 3 with it, and the annular A heat preservation device 4 is arranged in the cavity 3 and filled with heat preservation materials, and a heating system 5 is arranged at the bottom of the inner shell 2 .

[0010] When in use, the sample cup is now placed in the inner shell 2, the heat preservation device 4 in the annular cavity 3 keeps the sample warm, and the heating system 5 heats the oil, and accurate measurement can be carried out after reaching the measurement temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com