Substrate-formed part preheating device and method of additive and subtractive manufacturing equipment

A preheating device and additive manufacturing technology, which is applied in the field of substrate-formed part preheating device of additive and subtractive material manufacturing equipment, can solve problems such as difficult preheating of formed parts, achieve low cost, reduce labor costs, and reduce local preheating. The effect of hot time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

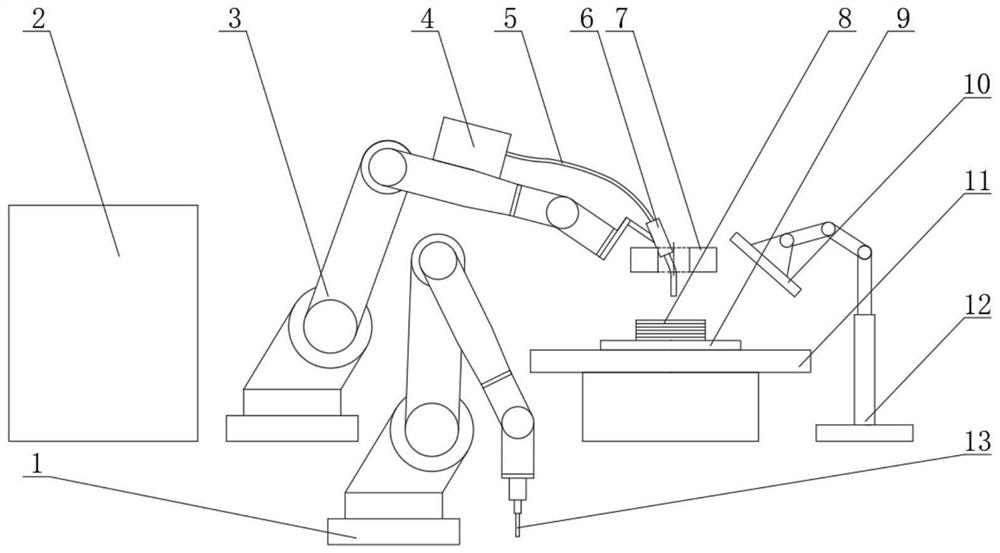

[0025] see figure 1 , a substrate-formed part preheating device for additive and subtractive material manufacturing equipment, comprising an additive robot 3, a material subtractive robot 1, a plate-shaped far-infrared heater 10 and an annular far-infrared heater 7, an additive robot 3, a material subtractive robot The robot 1 , the plate-shaped far-infrared heater 10 and the ring-shaped far-infrared heater 7 all face the molding 8 on the substrate 9 . The additive robot 3 performs additive manufacturing on the substrate 9 through the metal printing head 6 , and the annular far-infrared heater 7 is fixed on the outside of the metal printing head 6 . The plate-shaped far-infrared heater 10 is fixed on the adjustment bracket 12 . The additive robot 3 is connected to the wire feeder 4 , and the wire feeder 4 is connected to the metal printing head 6 through the wire fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com