New lubrication oil quality spectrum rapid determination method

A rapid determination and lubricating oil technology, applied in the direction of color/spectral characteristic measurement, measurement device, material analysis through optical means, etc., to achieve the effect of improving monitoring ability, multiple parameters, and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

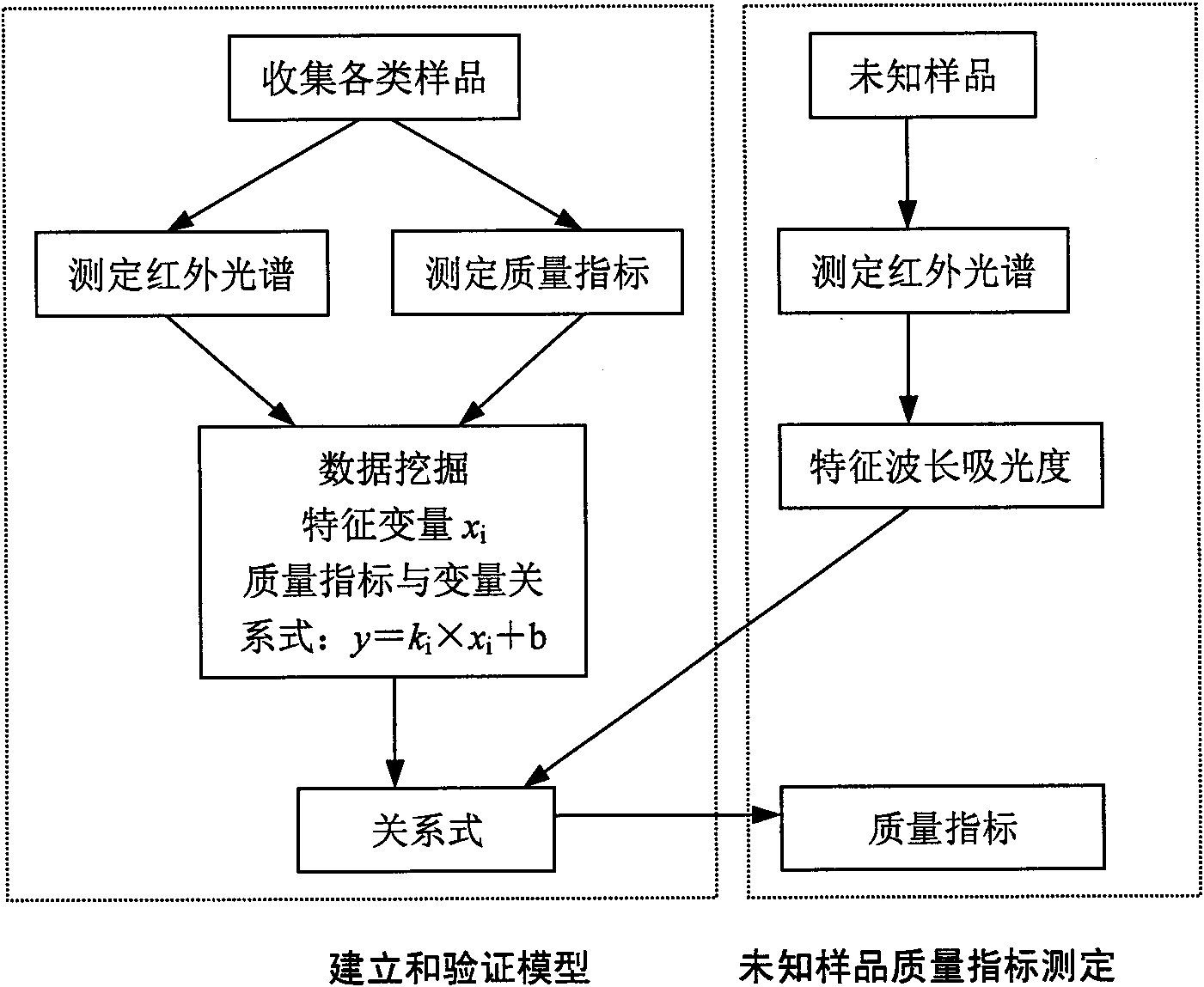

Problems solved by technology

Method used

Image

Examples

example 1

[0059] Example 1: Establishment and investigation of the regression equation for the determination of lubricating oil chemical composition by transmission method

[0060] 1) Collect training set samples

[0061] 125 lubricating oil samples were collected, including 86 internal combustion engine oils, 26 hydraulic oils, and 13 gear oils, whose manufacturers include Shell, ESSO, Mobil, MOBIL, Great Wall and Kunlun, etc.

[0062] 2) Determining the infrared spectrum and various quality indicators of the lubricating oil sample;

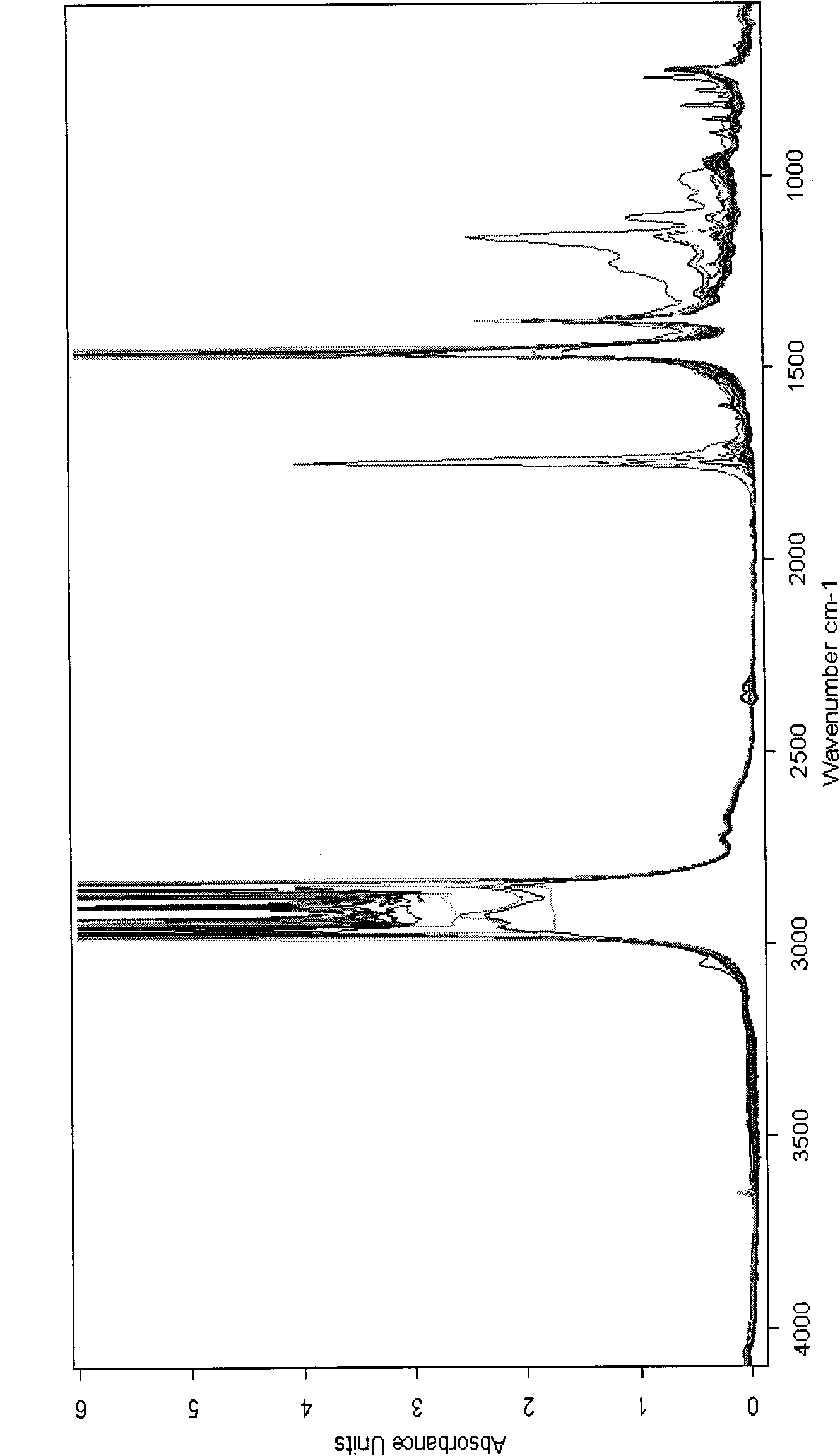

[0063] Use the Tensor 27 mid-infrared spectrometer to measure the infrared spectrum of the above lubricating oil, the spectral range: 550-4100cm -1 . Transmission sample cell, the optical path is 0.1mm. For the measured infrared spectrum, please see figure 1 .

[0064] Table 1 lists the units, standard methods, reproducibility requirements and repeatability requirements of each quality parameter. The quality indexes of various lubricating oils are s...

example 2

[0078] Example 2: Investigation on the accuracy of other quality indicators of lubricating oil measured by transmission method

[0079] 1) Collect training set

[0080] The training set is the same as in Example 1.

[0081] 2) measure the infrared spectrum and every quality index of lubricating oil, and measuring method and result are identical with embodiment 1.

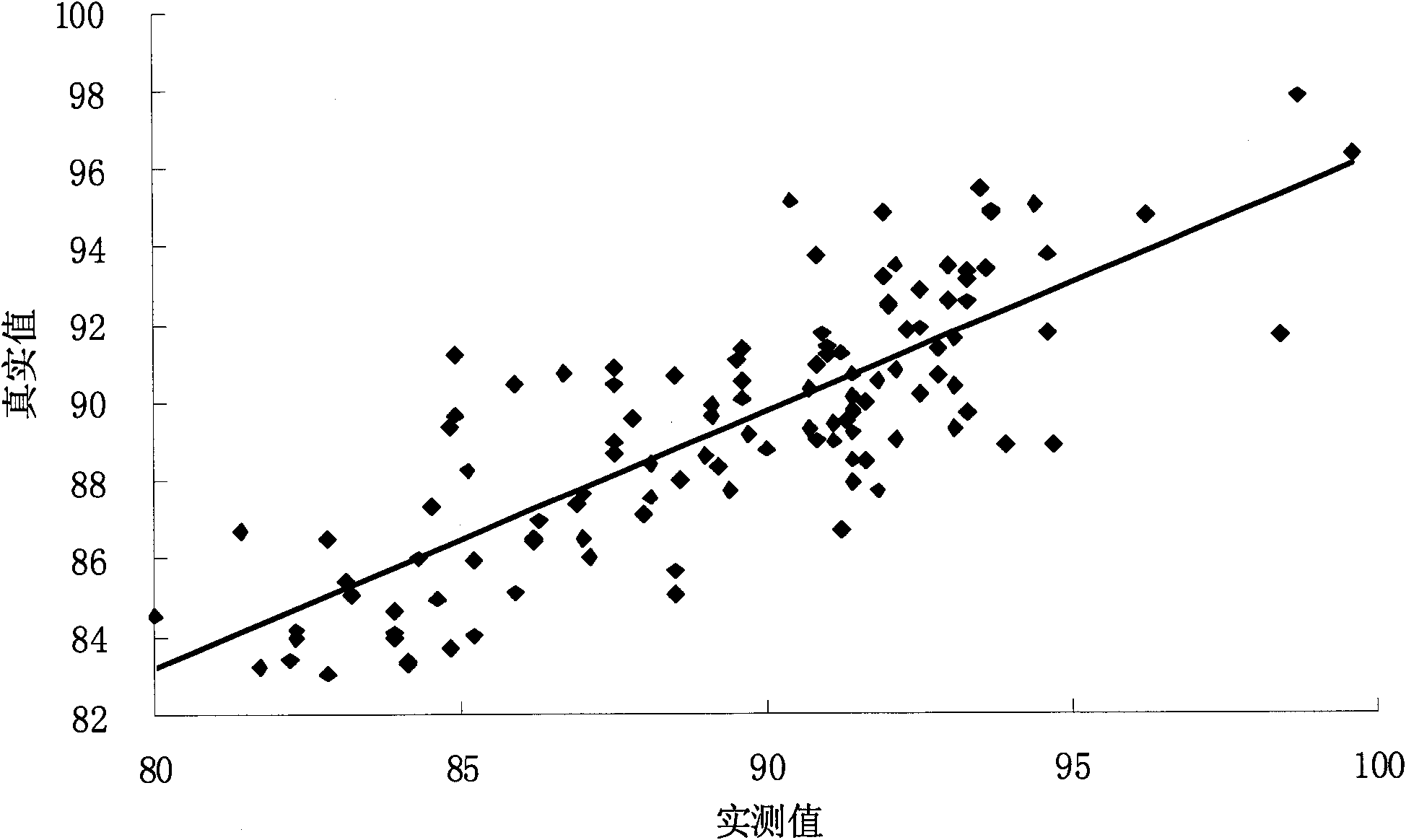

[0082] 3) Evaluate the performance of the multiple linear regression equation

[0083] According to the steps of Example 1, the regression equations of each physical and chemical quality index were established. The preferred characteristic wavelengths of each physical and chemical quality index are shown in Table 5, and k is calculated according to the physical and chemical quality indexes measured at the characteristic wavelength i And b value, establish the regression equation of each physical and chemical quality index. Then take the training set as the unknown sample, use the established equation to measure ...

example 3

[0093] Example 3: Investigation on the Accuracy of Lubricating Oil Quality Index Determination by ATR Method

[0094] 1) Collection of training set

[0095] The training set is the same as in Example 1.

[0096] 2) Determination of infrared spectrum and various quality indicators of lubricating oil

[0097] Use the Tensor 27 mid-infrared spectrometer to measure the infrared spectrum of the above lubricating oil, the spectral range: 550-4100cm -1 . ATR sample cell, reflect 10 times. Each quality index measuring method and result are identical with embodiment 1.

[0098] 3) Evaluate the performance of the multiple linear regression equation

[0099] According to the steps of Example 1, the regression equations of each physical and chemical quality index were established. Then take the training set as the unknown sample, use the established equation to measure its physical and chemical quality index, and compare with the real value, calculate the correlation coefficient R a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com