Carbon steel pile toe for PHC high-strength concrete pipe pile

A high-strength concrete and carbon steel technology, used in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of limited strength, poor corrosion resistance, affecting the depth of pipe piles, and improve load-bearing capacity and corrosion resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

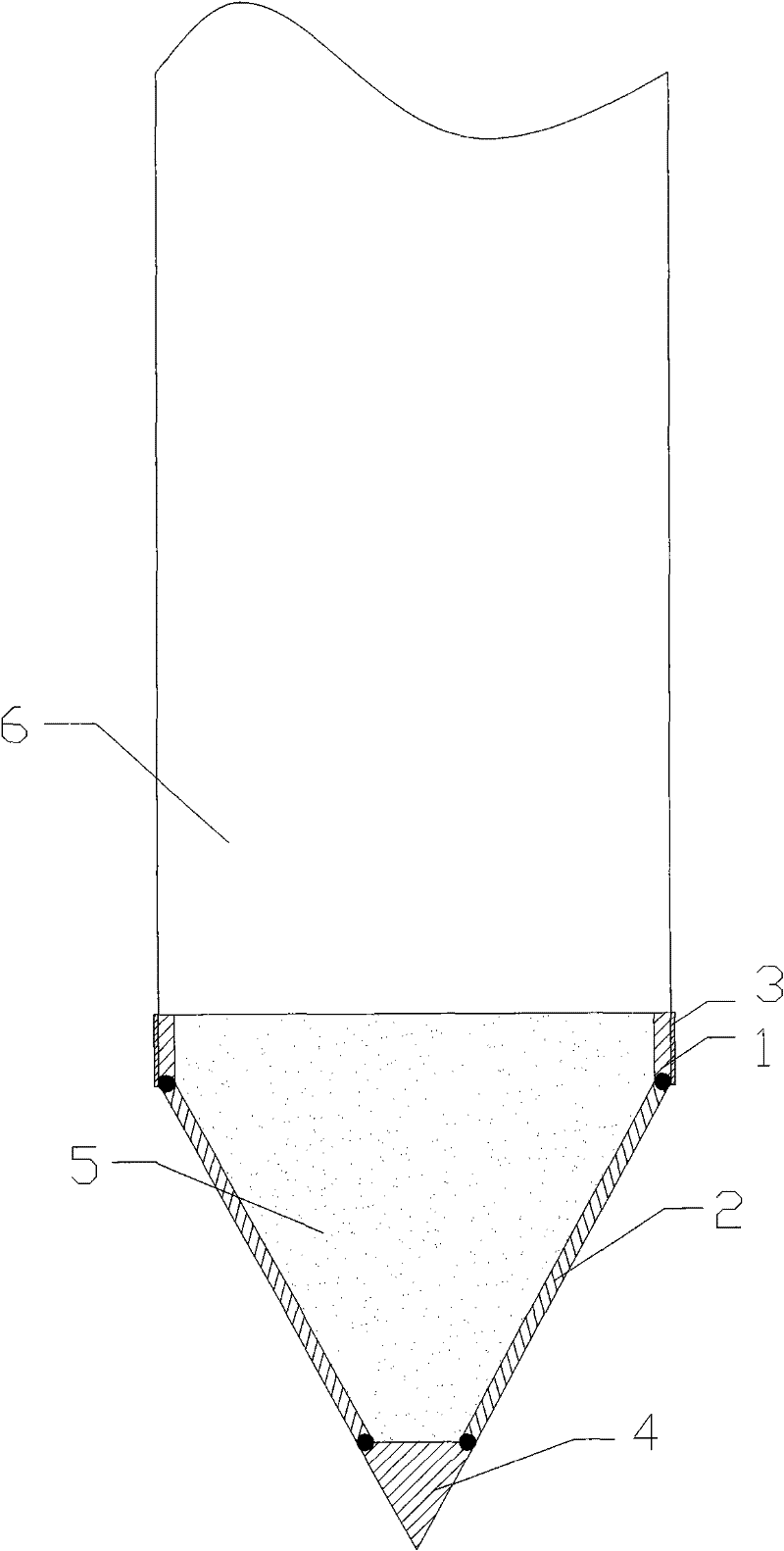

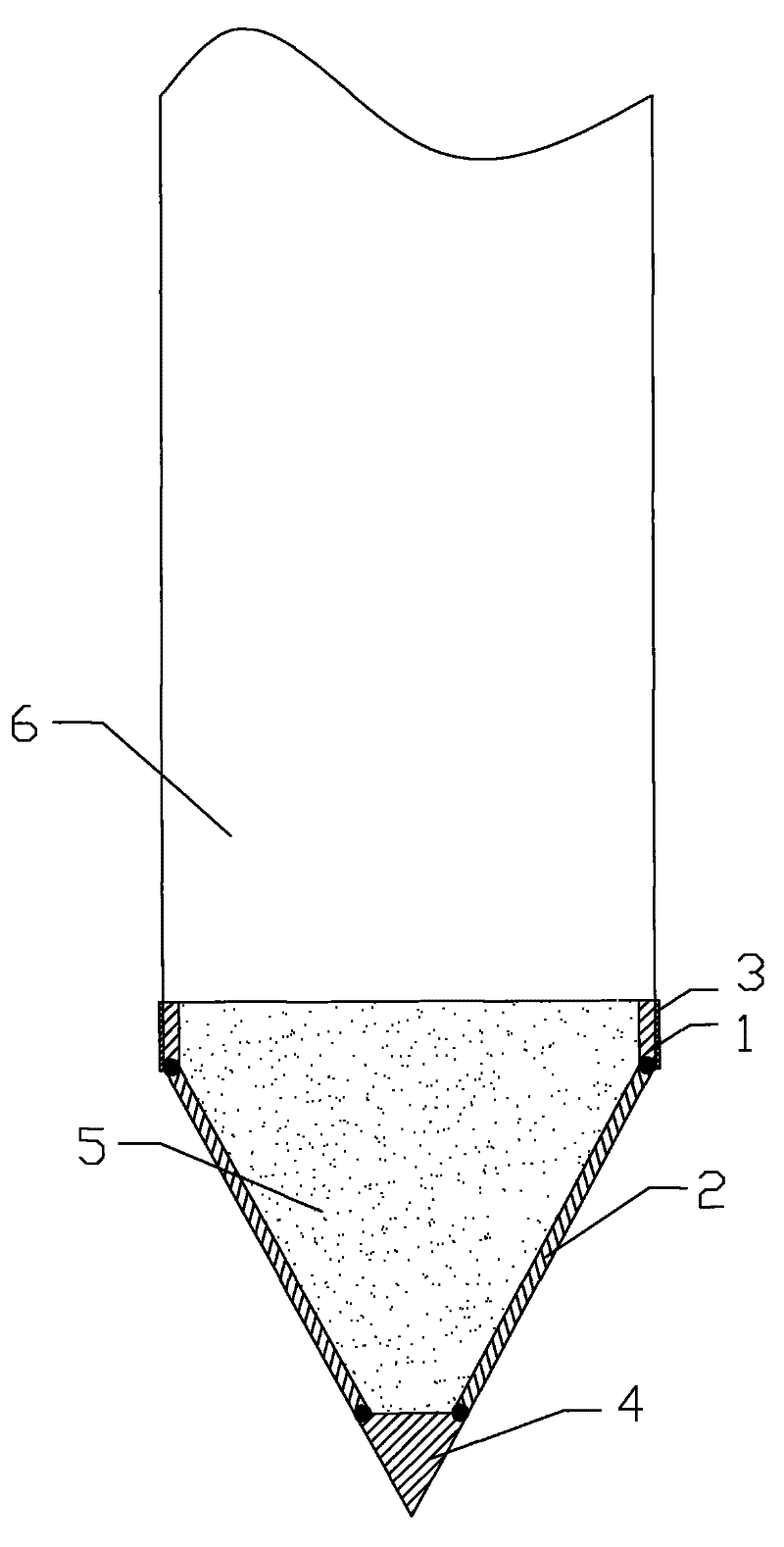

[0015] Such as figure 1 As shown, a carbon steel pile point of a PHC high-strength concrete pipe pile is composed of a welded pile point and a pipe pile 6, and the height and width of the weld seam between the pile point and the pipe pile are above 8mm. Among them, the pile tip is provided with a conical carbon steel bottom angle 4, and 8 to 10 carbon steel bars 2 are welded on the top, covered with steel mesh, and an annular steel plate 1 is welded on the carbon steel bar 2, and on the top of the annular steel plate 1 A thin steel plate hoop 3 is spot-welded on the outside, and concrete 5 is poured in the above-mentioned pile point steel parts. The grade of concrete poured into the pile point steel parts is C90, and anti-corrosion agent is added. Concrete is poured into the pipe core of the pipe pile, its grade is C80, and steel bars are poured. The height of the above-mentioned carbon steel bottom corner is 150mm. The height of the carbon steel bar is 500mm; the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com