Construction method of concrete slab based on welded steel mesh and cement pressure plate

A technology of welded steel mesh and cement pressure plate, which is applied in the direction of building structure, building, floor slab, etc., can solve the problems of impossibility of industrialized production and unsatisfactory strength of formwork without dismantling, and achieve low cost, good construction quality, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

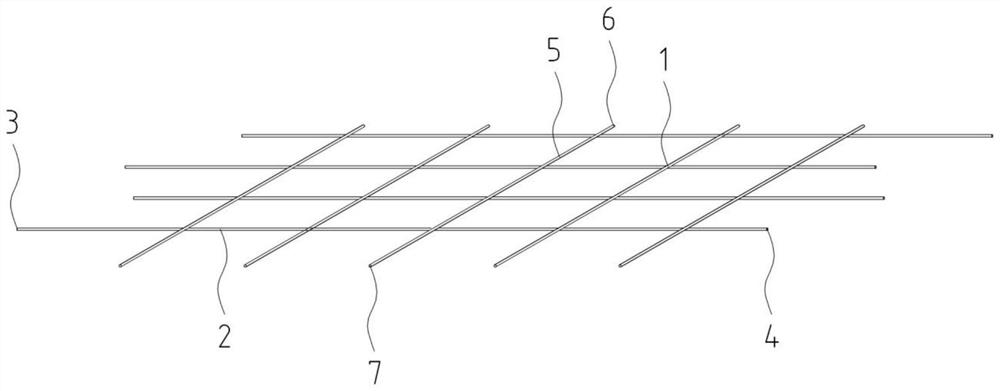

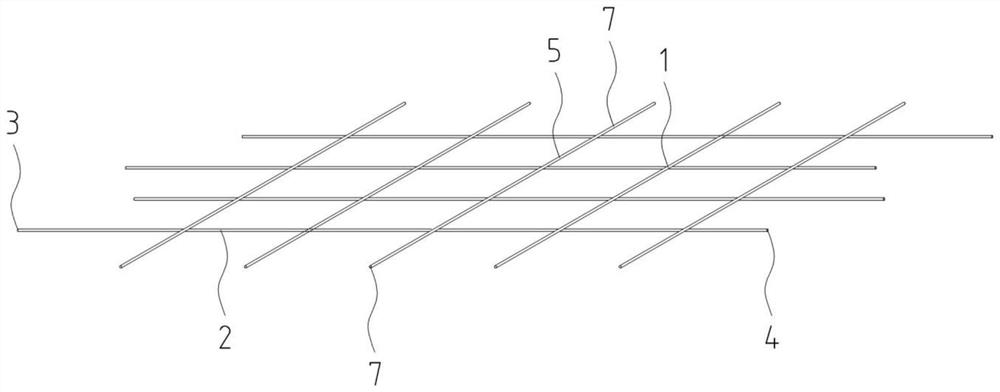

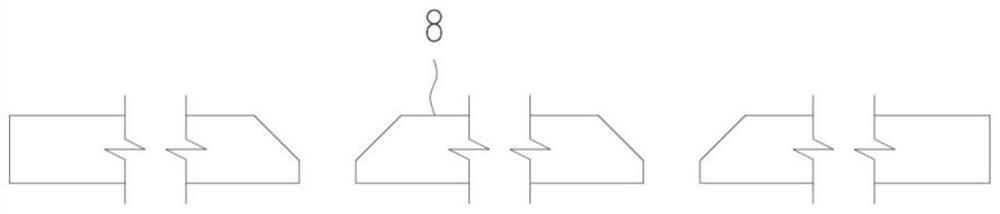

[0034] Concrete slab construction methods based on welded steel mesh and cement pressure slabs, such as Figure 1 to Figure 10 As shown, the following steps are included, and the following steps are carried out in sequence,

[0035] Step 1. Preparation of welded steel mesh 1

[0036] Such as figure 1 and figure 2 As shown, the conventional production method of welded steel mesh is improved, and the cutters of the welded steel mesh 1 longitudinal cutting device are arranged staggered according to the spacing of the steel bars, so that the ends of the longitudinal steel bars 2 are made into two kinds of length intervals. One end is a longer longitudinal steel bar extending into the support end 3, and the length of the longitudinal steel bar extending into the support end 3 is determined according to the design size. The other end of the longitudinal steel bar 2 is a shorter longitudinal steel bar free end 4, and the longitudinal steel bar free end 4 The length of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com