Energy-saving heating device of reaction kettle

A heating device and reaction kettle technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing production costs, affecting the reaction of the medium, and high production costs, and reducing industrial costs. Electricity cost, high economic benefits, and the effect of solving electricity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

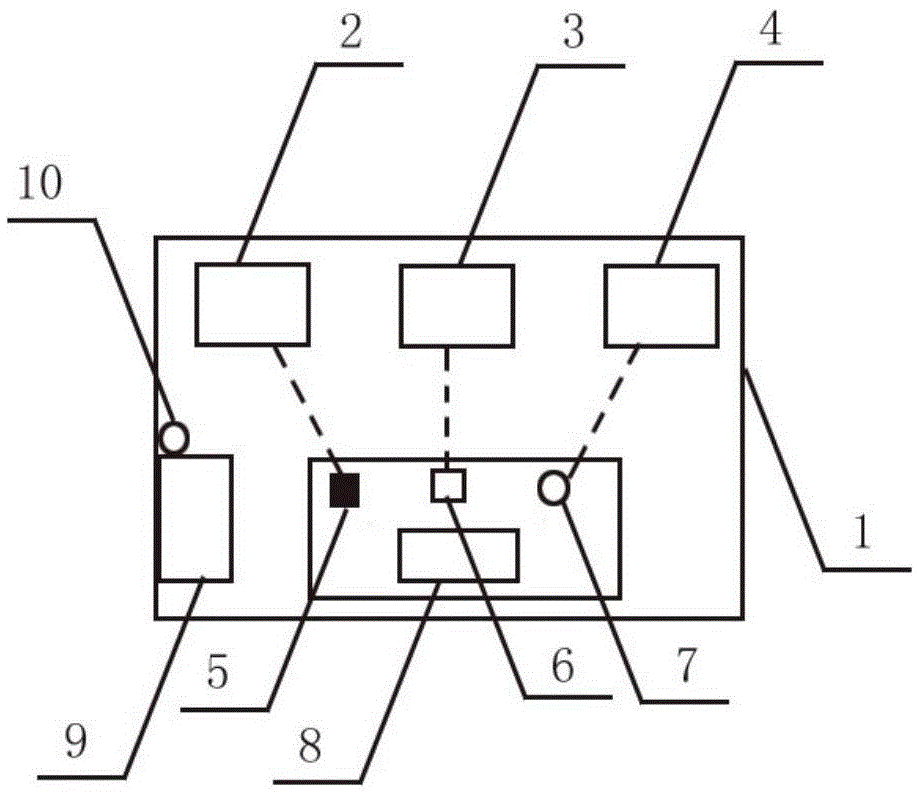

[0012] Example: as shown in the drawings. An energy-saving heating device for a reactor, comprising a frame (1). The frame (1) includes an air energy absorption device (2), a wind induction device (3), and a solar light receiving plate (4) arranged side by side on the frame (1) The top part is respectively connected with the corresponding compressor device (5), wind power conversion device (6), and solar energy analysis device (7), and is converted into the heating power required by the reactor through data analysis of the central control device (8).

[0013] An energy-saving heating device for a reactor. The frame (1) partially uses the principle of a heat pump water heater to heat the reactor and saves electricity.

[0014] An energy-saving heating device for a reactor. Wind energy and solar energy are mainly used for power reserve and used for power transmission when the reactor is converted into electric heating.

[0015] An energy-saving heating device for a reactor is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com