Adsorption tower and system for recovering solvent oil

An adsorption tower, solvent oil technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of difficult renewal and recovery, large operating resistance, short life of adsorbent materials, etc., and achieve good physical and chemical stability and thermal stability. performance, saving production costs, and facilitating regular replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

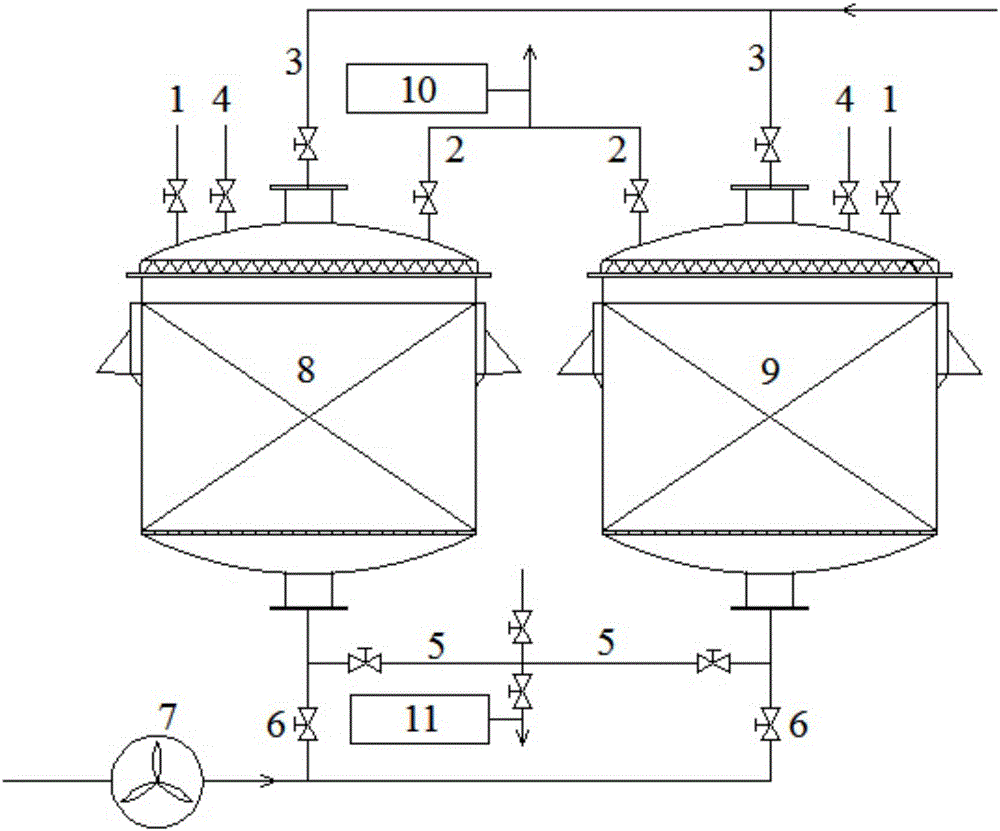

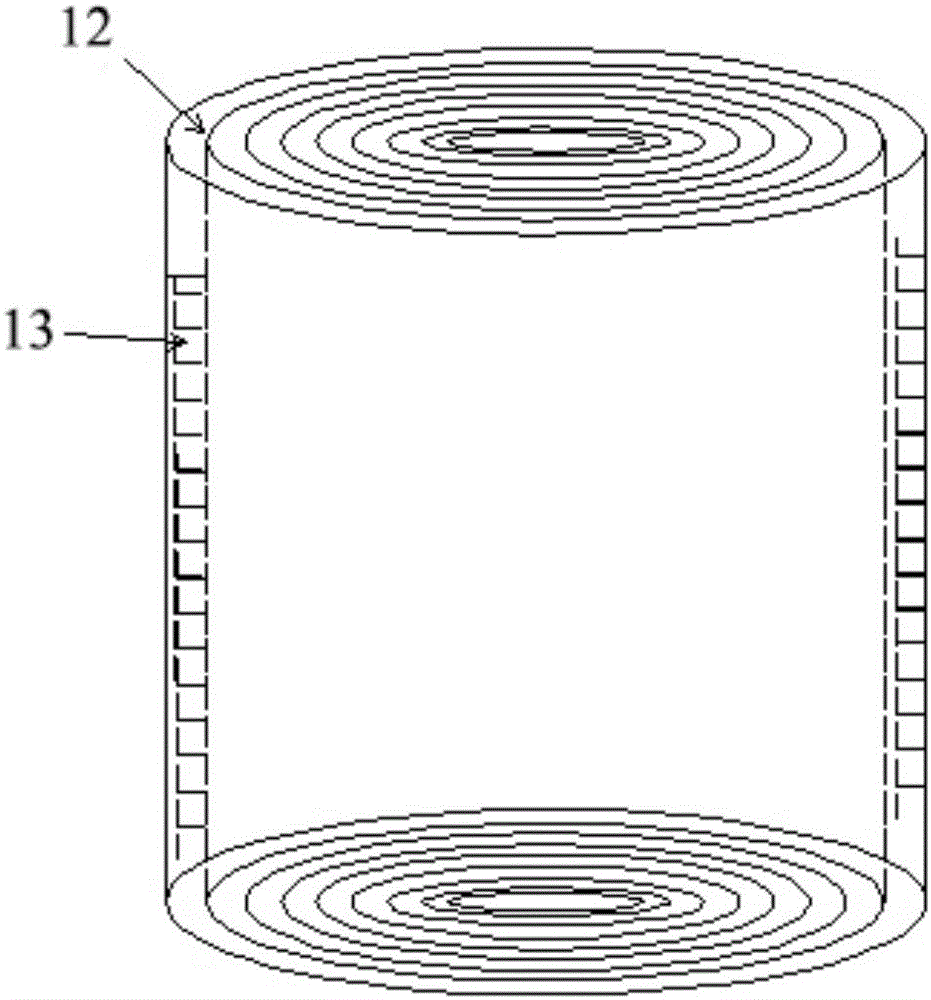

[0038] like figure 2 As shown, an adsorption tower for recovery of solvent oil mainly includes a cylinder, a cylindrical sleeve 12, a porous baffle, a metal filter screen and a solid adsorption material 13, wherein the cylindrical sleeve 12 is arranged inside the cylinder, and the same The number of cylindrical sleeves 12 in the cylinder is three, and the radius range is 0.5m-1.0m. A porous baffle is placed horizontally at the bottom port of the cylinder. The aperture of the porous baffle is 10 meshes, and its peripheral edge is fixed on the inner wall of the cylinder to support the cylindrical sleeve 12 inside the cylinder. In addition, the porous baffle is covered with There is a metal filter screen, and the aperture range of the metal filter screen is 100-150 mesh. Solid adsorption material is filled between the cylindrical sleeves, specifically spherical granular resin, with a specific surface area of 500m 2 / g. The cylinder is covered with an arc-shaped cover, which...

Embodiment 2

[0053] This embodiment also provides a kind of adsorption tower that is used for solvent oil recovery, mainly comprises cylinder, cylinder sleeve 12, porous baffle plate, metal filter screen and solid adsorption material 13, and this adsorption tower structure is the same as embodiment 1, The difference: the number of cylindrical sleeves 12 is 10, and the radius range is 0.5m-1.0m. The aperture of the porous baffle placed horizontally at the bottom port of the cylinder is 30 mesh, and the aperture of the metal filter screen above the porous baffle is in the range of 250-300 mesh. The specific surface area of the spherical granular resin filled between the cylindrical sleeves is 1000m 2 / g. All the other are with embodiment 1.

Embodiment 3

[0055] The structure of the adsorption tower provided by the present embodiment and the solvent oil recovery system is the same as implementation 3, and the difference is that the processes of the adsorption tower A8 and the adsorption tower B9 are different, as follows:

[0056] see figure 1 , set the adsorption tower B9 to the adsorption mode. Using the induced draft fan 7, the solvent oil-containing waste gas discharged from the stripping kettle is sent to the adsorption tower B9, and the tail gas concentration detector 10 of the adsorption tower detects the concentration of the tail gas online. When the detected concentration exceeds the set value of 70mg / m 3 Finally, first open the inlet pipeline 6 valve of adsorption tower A8, then close the inlet pipeline 6 valve of adsorption tower B9. The adsorption tower B9 enters the desorption mode, and the adsorption tower A8 enters the adsorption mode. Open the valve 3 of the steam pipeline and the valve 5 of the oil outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com