Device and method for installing parts on both sides of pipeline

An installation device and installation method technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult installation, harsh requirements, interruption of industrial production, etc., and achieve low cost and accurate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

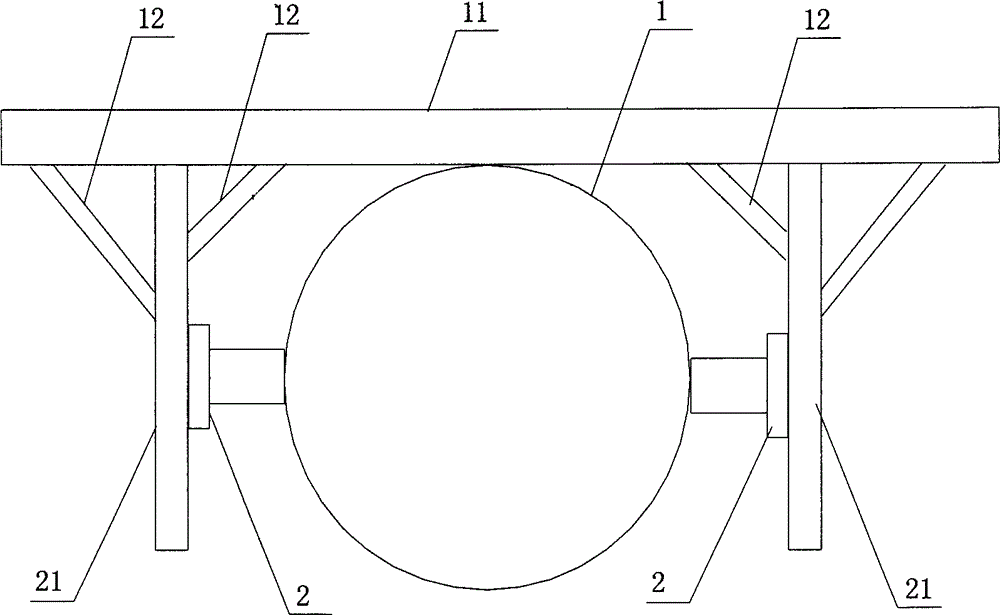

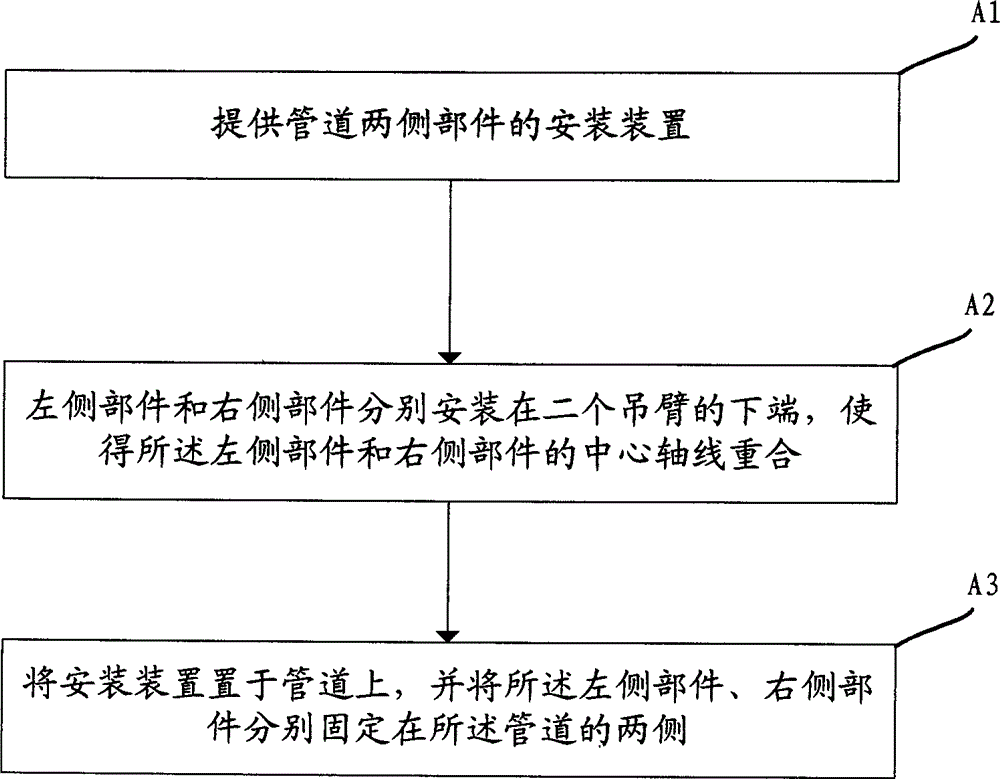

[0042] figure 1 Schematically provides a simplified structural diagram of the installation device for the parts on both sides of the pipeline (left side part, right side part) according to the embodiment of the present invention, as figure 1 As shown, the installation device includes:

[0043] A crossbeam 11; the crossbeam 11 can adopt a channel steel with sufficient strength;

[0044] Two booms 21, the upper ends of the two booms 21 are respectively arranged on both sides of the beam 11, and the lower ends are respectively used to fix the left part and the right part 2, such as welding flanges; The angle between the arm and the beam is fixed. The boom can adopt channel steel with sufficient strength.

[0045] In order to improve the accuracy of positioning and reduce the difficulty of debugging, preferably, the angle between the two booms and the beam is 90 degrees.

[0046] In order to ensure that the positions of the left part and the right part installed at the lower e...

Embodiment 2

[0064] An application example of the installation device and method for the parts on both sides of the pipeline according to Embodiment 1 of the present invention in the installation of a laser gas analyzer.

[0065] In this application example, both the beam and the boom are made of channel steel, one end of the two booms is welded on the beam, and the lower end is provided with a mounting hole for the installation and fixing of the welding flange; the angle between the boom and the beam is 90 degrees. The distance between the two booms is greater than the outer diameter of the pipe.

[0066] The installation method of the parts on both sides of the pipeline of this embodiment is:

[0067] Use bolts and nuts to fix the two welding flanges on the lower ends of the two booms respectively, and ensure that the central axes of the two welding flanges coincide, and the distance between the two welding flanges is equal to the outer diameter of the pipe; The distance from the central...

Embodiment 3

[0071] An application example of the installation device and method for the parts on both sides of the pipeline according to Embodiment 1 of the present invention in the installation of a laser gas analyzer.

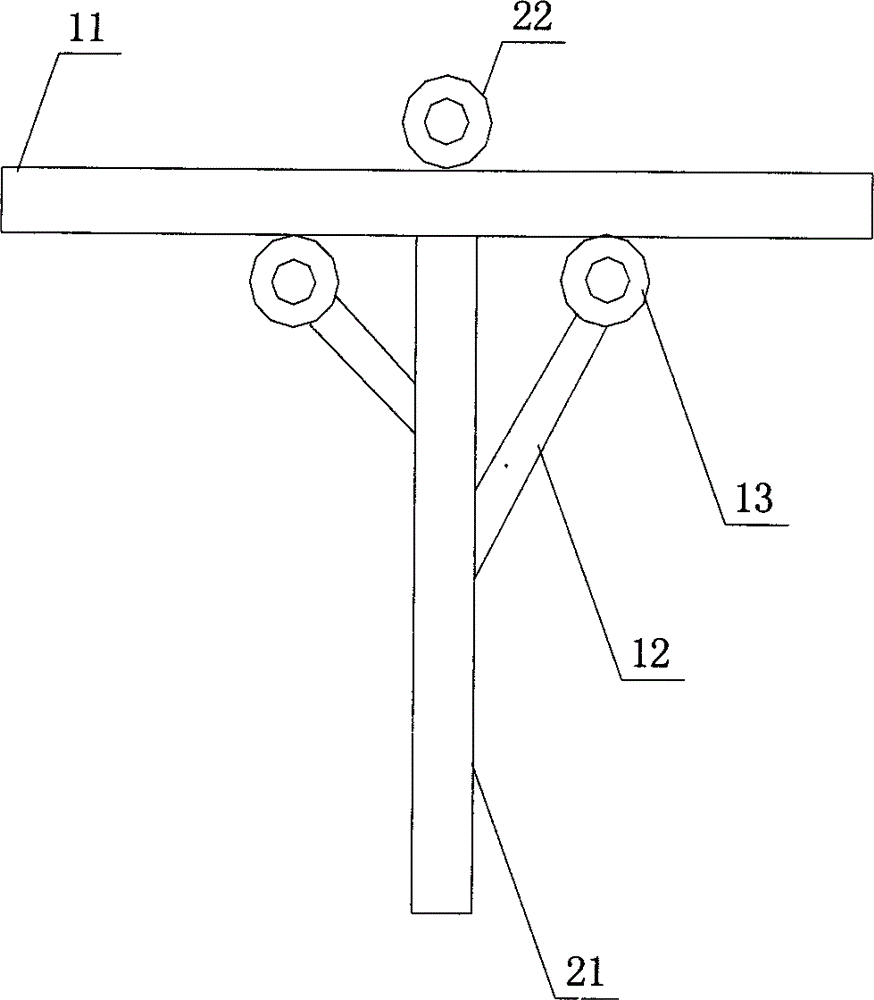

[0072] image 3 , 4 The front view and cross-sectional diagram of the installation device for the parts on both sides of the pipe in this embodiment are schematically given respectively, as image 3 , 4 As shown, the crossbeam 11 and the boom 21 are all selected channel steel, and there are through holes 24 along the length direction of the crossbeam 11. The upper end of the boom 21 is provided with two rollers 22, and the two rollers 22 are located in the throughholes 24 respectively. On the upper side of the cross beam 11 on both sides (that is, the roller is in the groove), the rotating shaft of the roller 22 is fixed on the boom 21 . Each boom 21 is equipped with two supports 12, one end of the supports 12 is provided with a roller 13, and the other end is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com