Flat key and locking machine

A key, flat technology, applied in the field of flat keys and locks, can solve the problems of high technological requirements for production and processing, complex internal structure, etc., to achieve the effect of compact structure, high production efficiency, and improved coding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

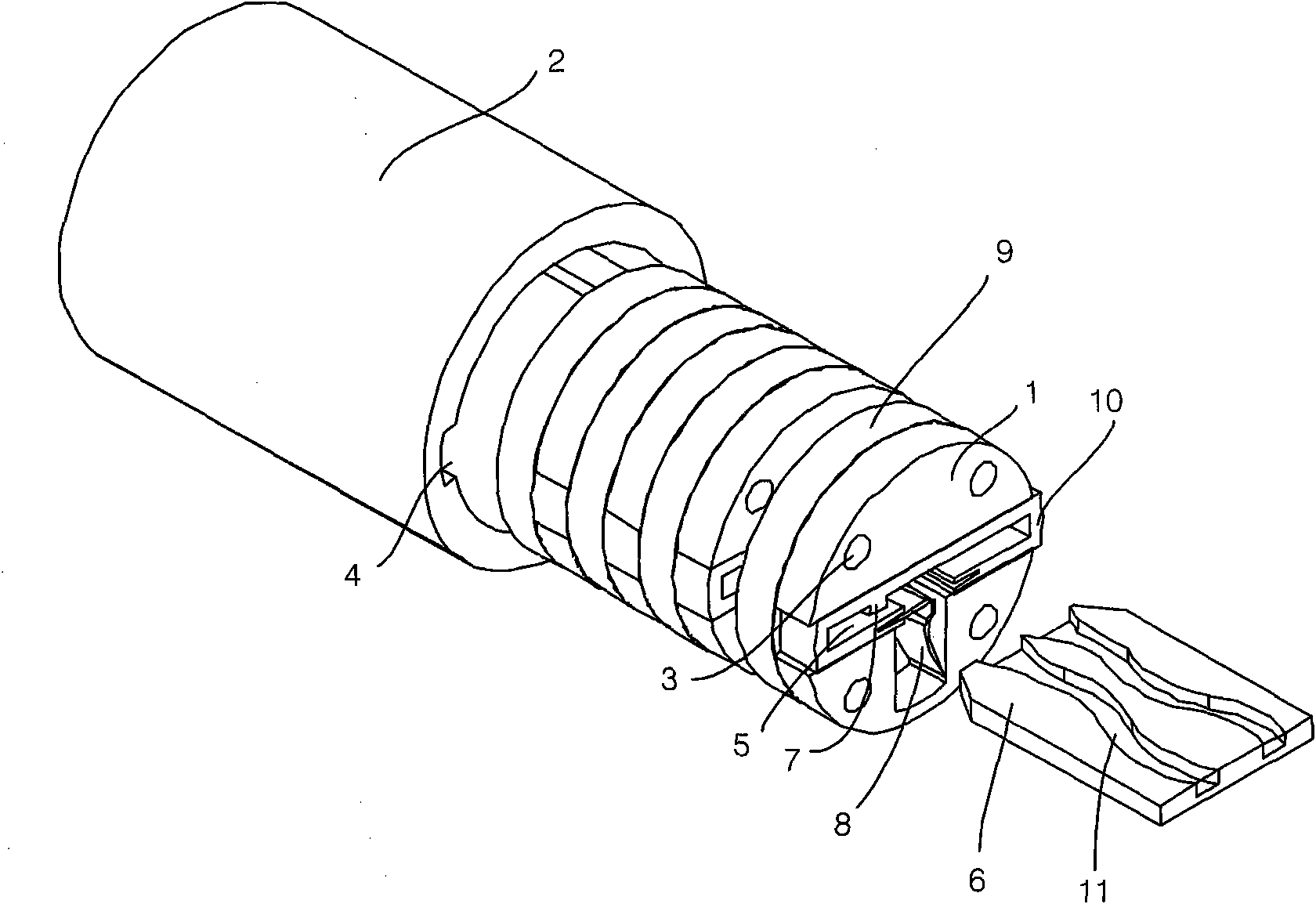

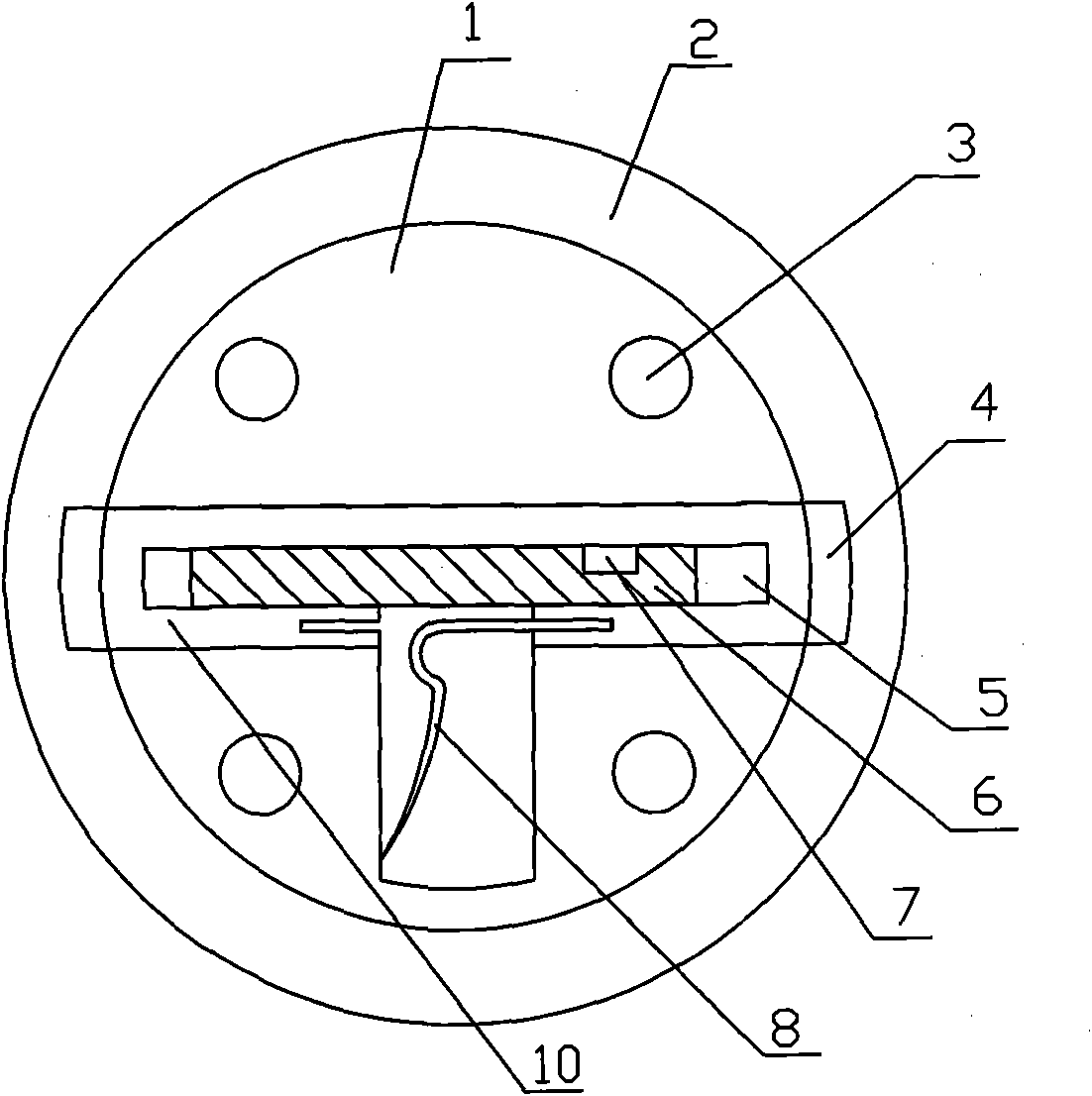

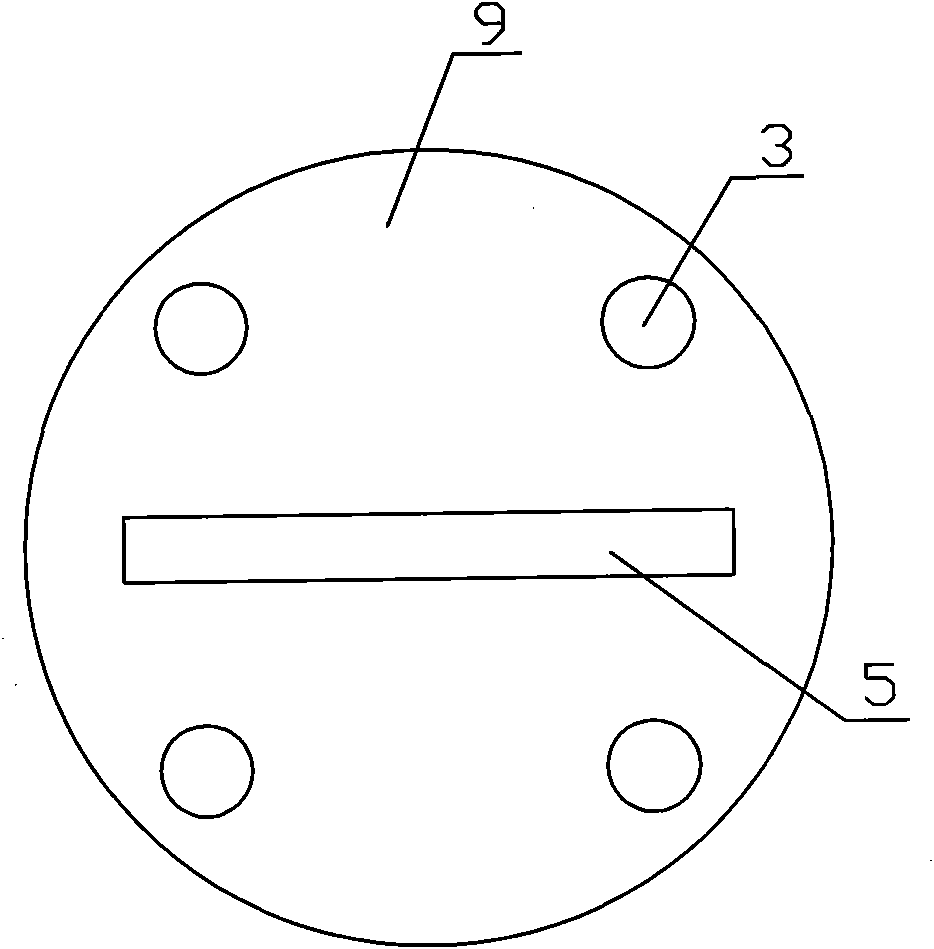

[0026] Specific embodiment 1 of the present invention, as figure 1 , 2 , shown in 3, a kind of flat key and lock machine, comprise flat key, shell 2, the rotatable lock core in shell 2, be formed with curved guide groove 11 on the flat surface of one side of flat key 6, along guide groove 11 Identification points are distributed, and a slide block 10 is installed in the lock cylinder. On the face opposite to the key, the slide block 10 is provided with a guide column 7 cooperating with the guide groove 11. Correspondingly, each slide block 10 is provided with a For the grooves 4, the two grooves 4 in each pair of grooves 4 are respectively located at both ends of the slider 10, and in the locked state, one of the two ends of the slider 10 slides into the groove in the housing 2 In 4, when unlocking, the key pushes the guide column 7 to drive the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com