Rapper unit with variable rapping mass and arm length

A rapping device and quality technology, applied in electrostatic separation, electrode cleaning and other directions, can solve the problems of rapping device rapping quality and arm length invariable, unable to better meet rapping requirements, unable to provide rapping force and other problems , to achieve the effect of simple structure, convenient production, and meet the requirements of rapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

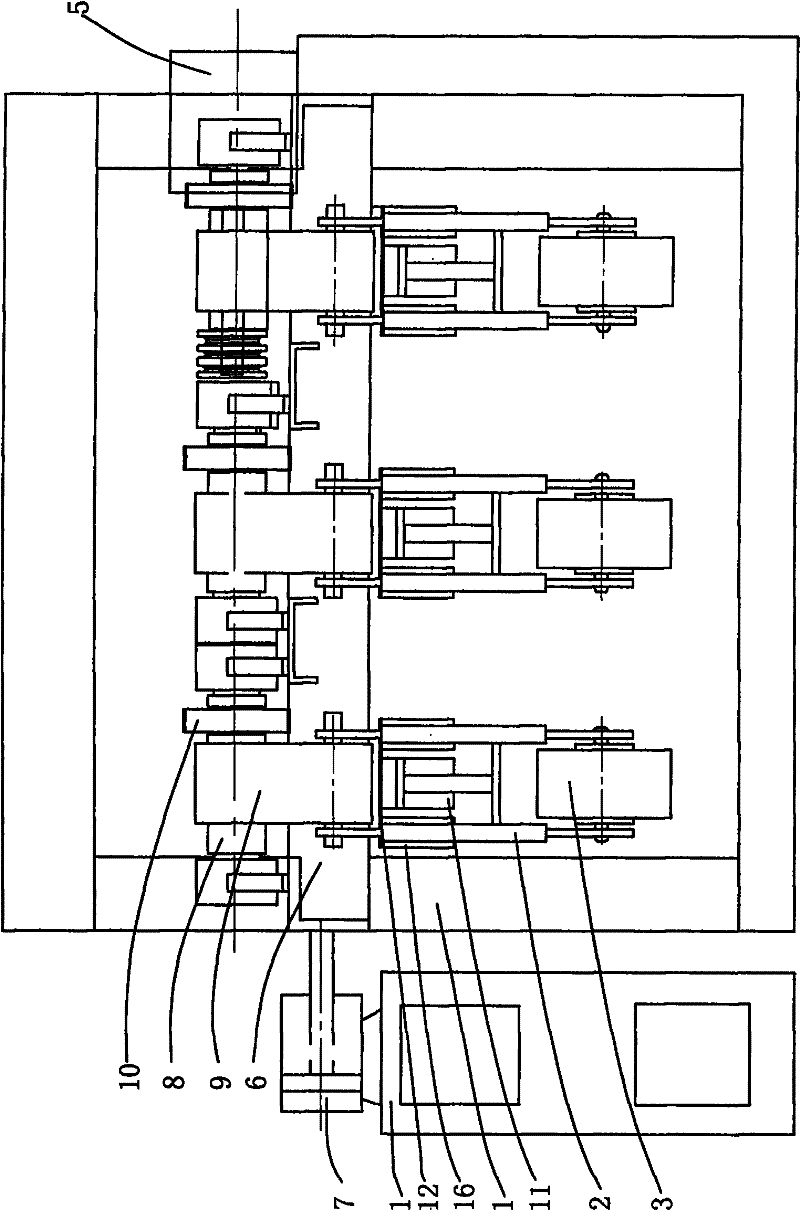

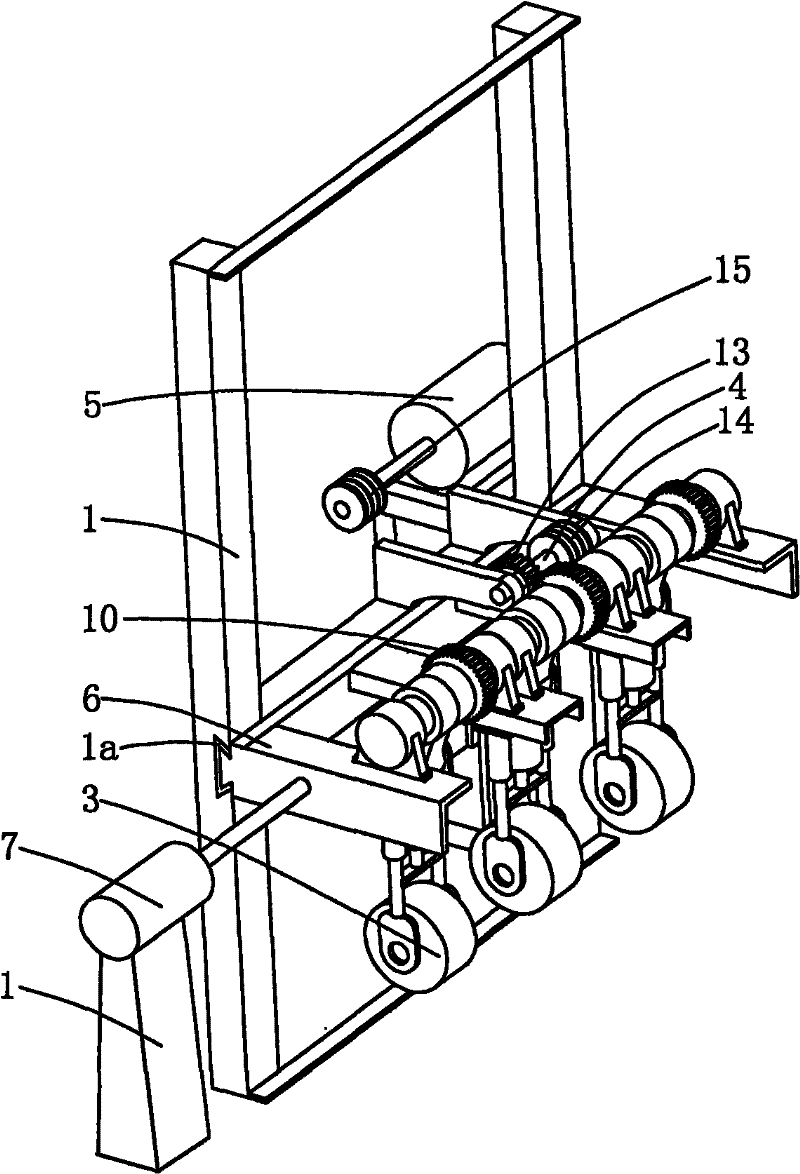

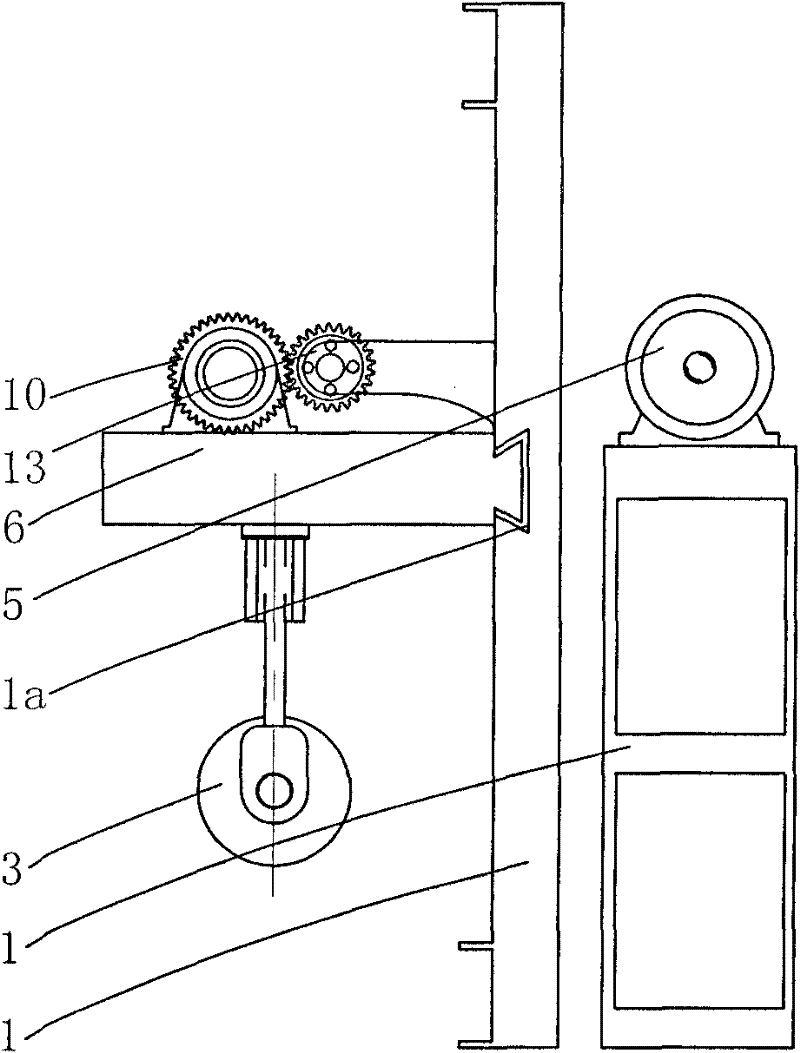

[0018] Such as Figure 1~5 As shown, a rapping device with variable rapping mass and arm length includes a base 1, a hammer arm 2, a hammer head 3, a spindle 4, a motor 5, a mounting seat 6, a pushing hydraulic cylinder 7, and a crankshaft 8. Components such as crank arm 9, driven gear 10, hydraulic cylinder 11, mounting plate 12, driving gear 13 and driven pulley 14, wherein the base 1 is provided with a mandrel 4, a motor 5, a mounting seat 6 and a driving hydraulic pressure Cylinder 7 has a dovetail groove 1a along the horizontal direction on the base 1, the rear end of the mounting seat 6 is installed in the dovetail groove 1a, and can slide in the dovetail groove 1a, and the mounting seat 6 is arranged on the pushing On the right side of the hydraulic cylinder 7, the left side of the mounting seat 6 is fixed with the piston rod extending end of the hydraulic cylinder 7.

[0019] from Figure 1~5 It can be seen from the figure that 3 rapping units are arranged side by si...

Embodiment 2

[0022] from Image 6 It can be seen from the figure that at least 3 rapping units are arranged side by side on the mounting base 6 from left to right. In this embodiment, the number of rapping units is 4, and the specific number can be adjusted accordingly according to the actual situation. The rest of the structure of this embodiment is completely the same as that of Embodiment 1, and will not be repeated here.

[0023] The working principle of the present invention is as follows:

[0024] Control the push hydraulic cylinder 7 to make the mounting seat 6 slide horizontally, and make the driving gear 13 mesh with the driven gear 10 of one of the rapping units, driving the hammer head 3 corresponding to the driven gear 10 to rap; The hydraulic cylinder 11 is controlled to make the hammer arm 2 expand and contract in the sleeve 16, thereby changing the length of the rapping arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com