Ink tank used for inkjet printer

An ink tank and inkjet printer technology, which is applied in printing and other directions, can solve the problems of opening the dry tank cover, high cost, complex shape, etc., and achieve the effect of easy switching and good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

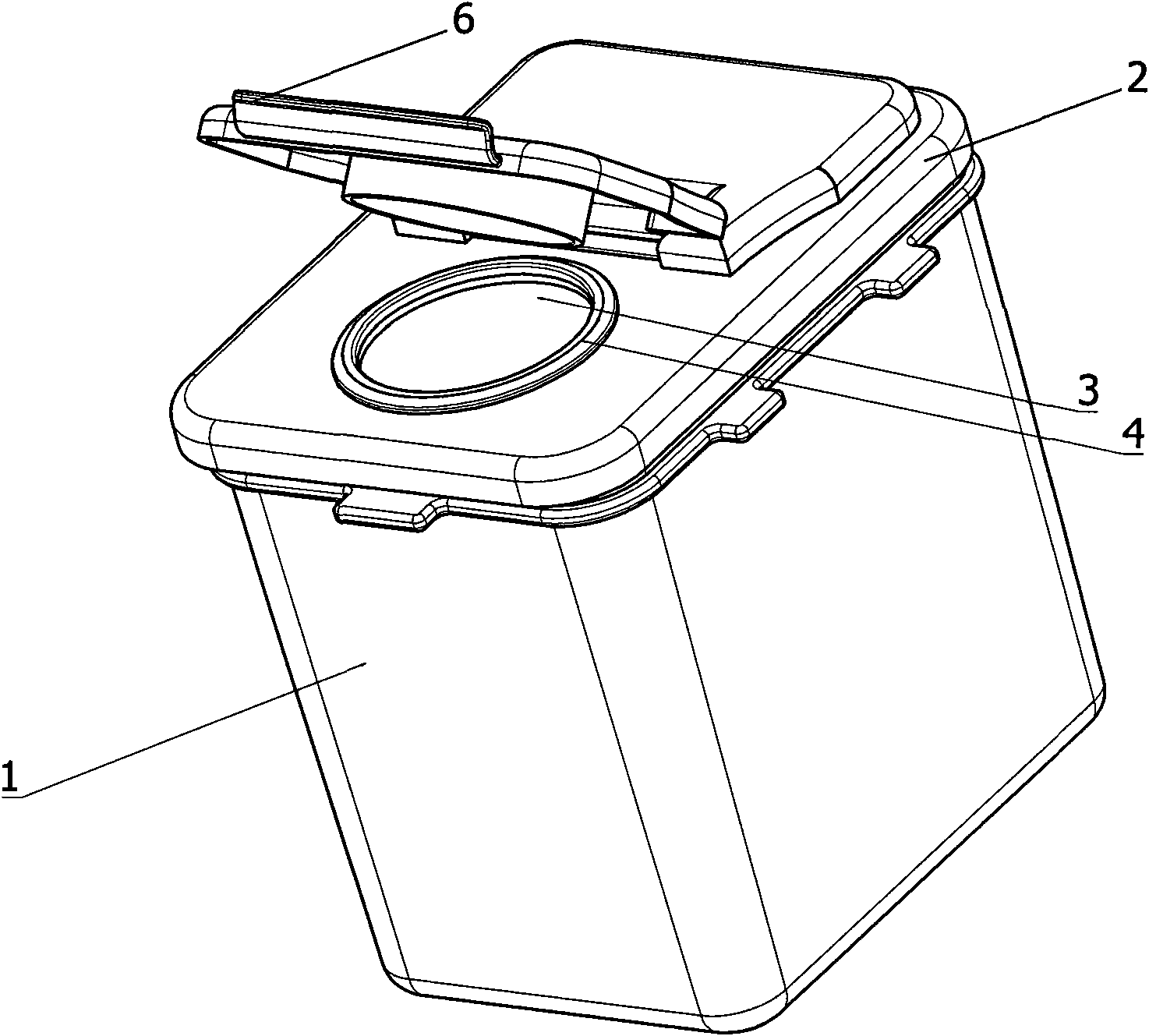

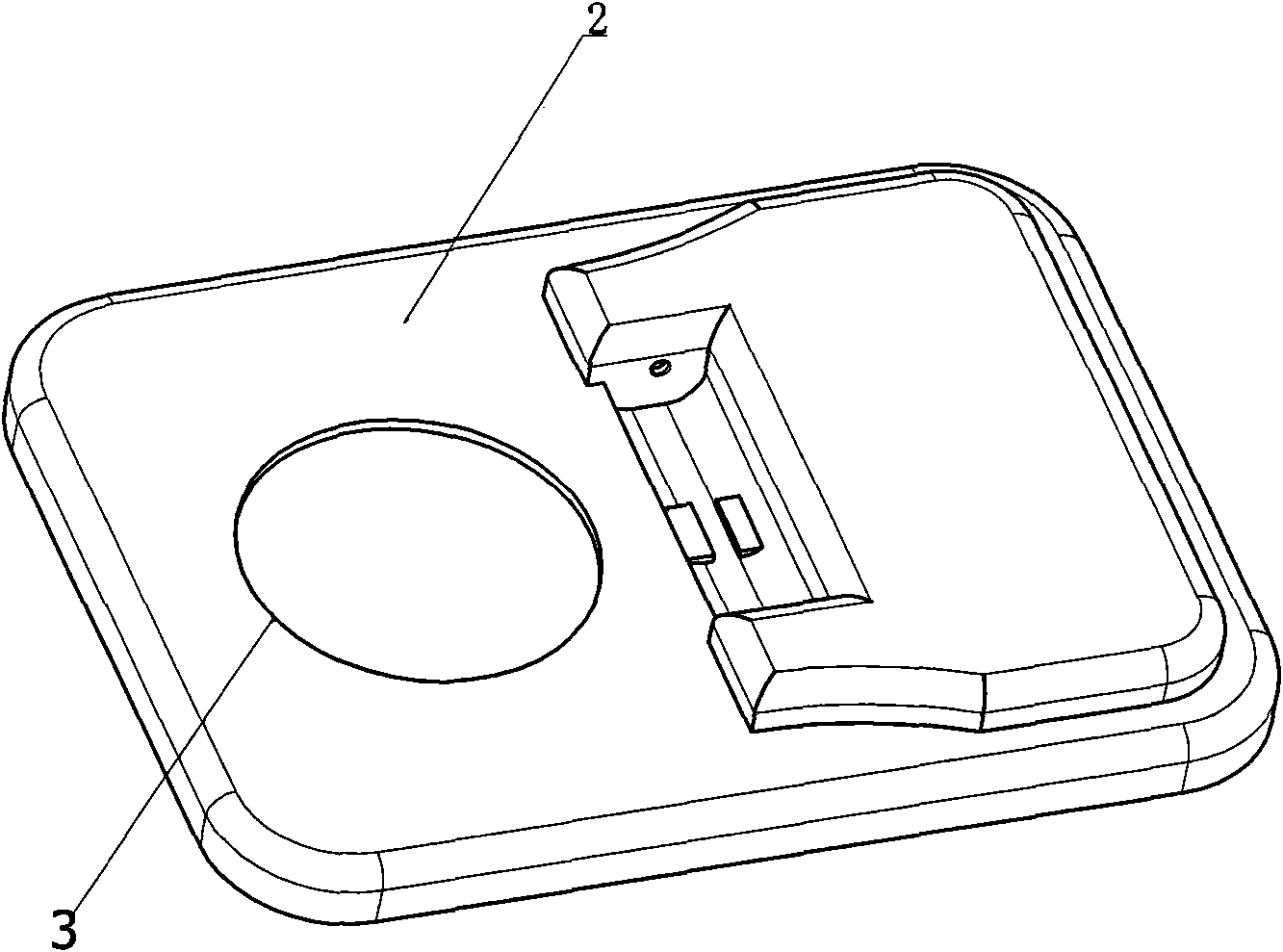

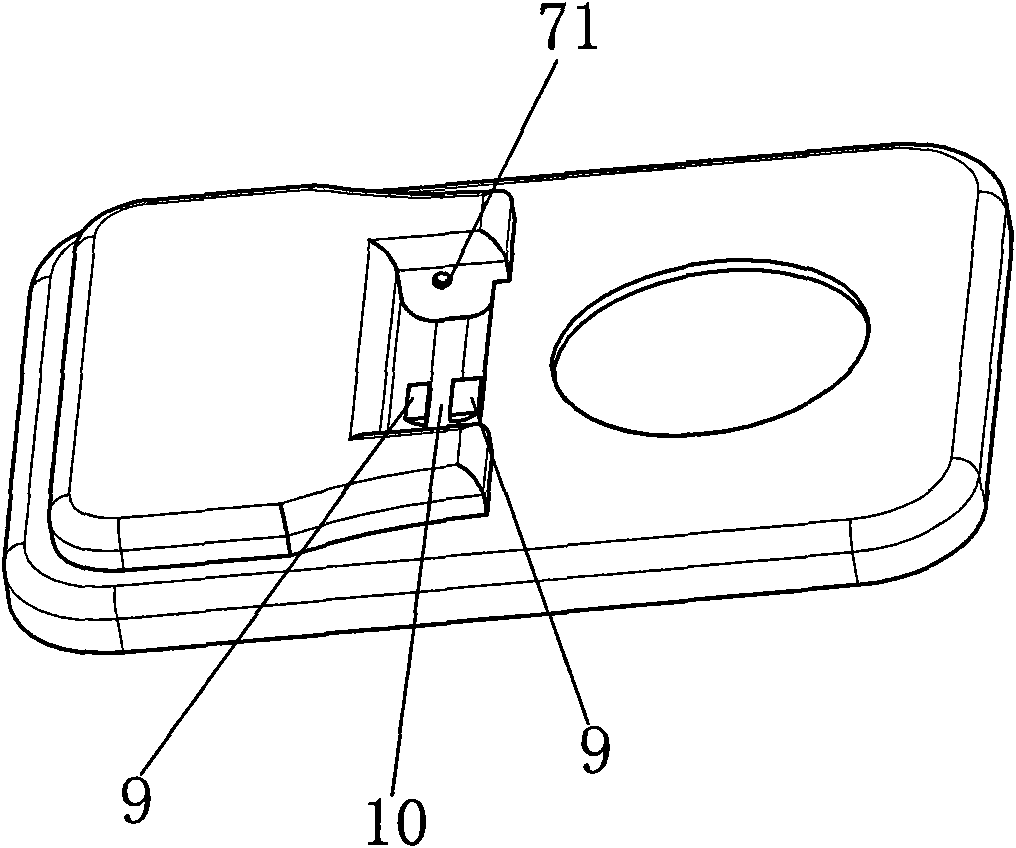

[0020] Such as Figure 1-Figure 5 As shown, the embodiment of the present invention provides an ink tank for an inkjet printer. The ink tank is molded by a mould, and it includes an ink tank container 1. The container 1 is provided with a tank cover 2, and the tank cover 2 is opened. There is an ink filling hole 3, and the opening of the filling hole 3 is provided with a sealing device 4, and the sealing device 4 is buckled on the tank cover 2 by an elastic sealing rubber ring. Such as Figure 5 As shown, the small can lid 6 is provided with a protruding ring 31 , and the protruding ring 31 is buckled on the sealing rubber ring 4 .

[0021] Such as Figure 2-Figure 5 As shown, the tank cover 2 described in the embodiment of the present invention is provided with a small tank cover 6 that can be fastened to the filling hole 3, and one end of the smal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap