Tent house

A technology for tents and skeleton parts, applied in the field of tents, can solve problems such as inability to solve geometrical shape contradictions, unfavorable large venues, poor effects, etc., and achieve the effect of reducing the possibility of rainwater retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

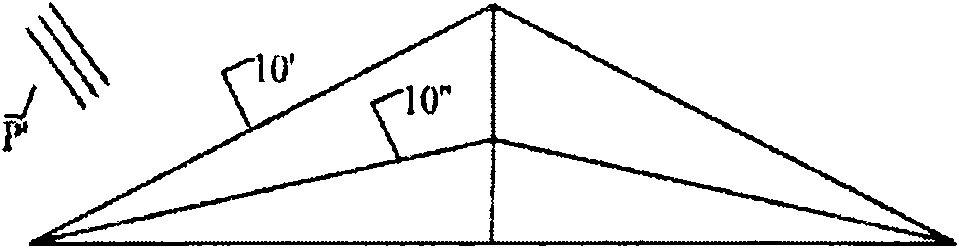

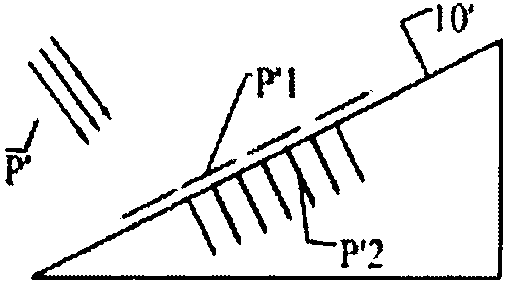

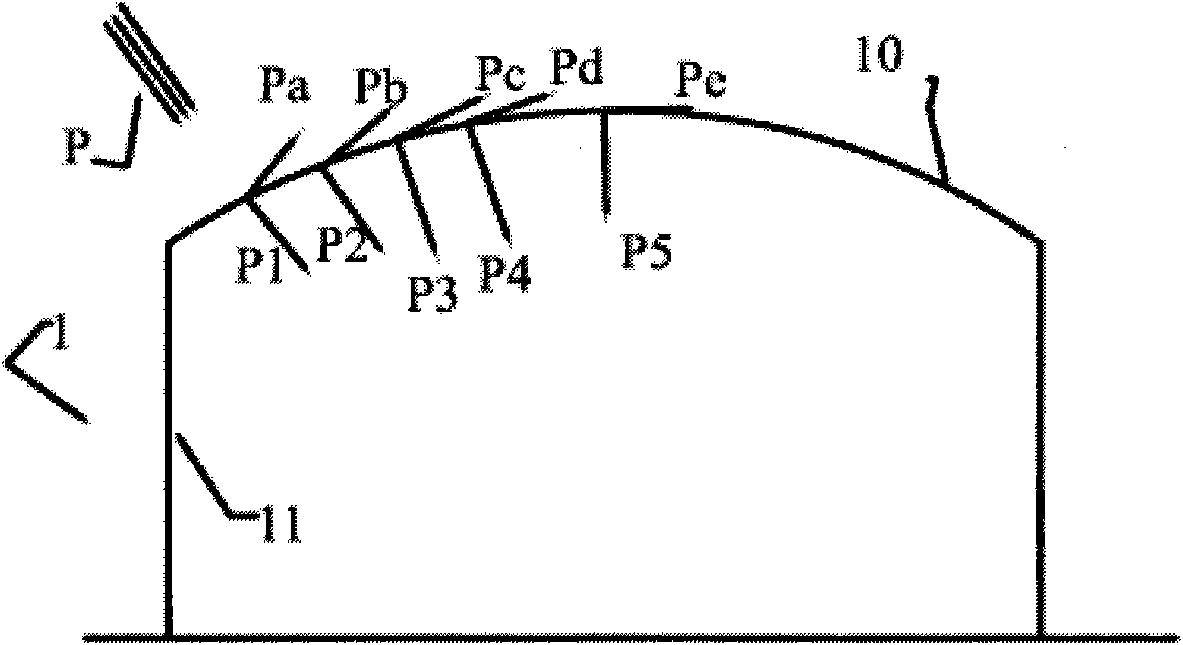

[0026] figure 1 The schematic diagram of the roof of the existing tent shown, as shown in the figure, the straight frame 10' in the roof is built into a triangle relative to the house, and the external wind force P' directly acts on the straight frame 10' of the roof. pass figure 2 The force analysis shown shows that the wind force P' can be decomposed into a component force P'1 upward along the straight frame 10' and a component force P'2 perpendicular to the direction of the straight frame 10'. From figure 2 It can be clearly understood that due to the use of the straight frame 10', all component forces will accumulate in one direction to form a larger resultant force. These larger resultant forces will inevitably require sufficient support from the tent, such as additional internal columns , support frame, etc. to resist the destructive force formed by the resultant force. These additional parts not only increase the cost and take up space, but also increase the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com