Self-adapted ultrasonic detector for online flaw detection for train wheel

A technology for train wheel and ultrasonic testing, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis. problems such as false triggering, to achieve the effect of ensuring measurement accuracy and reliability, accurate and reliable detection results, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

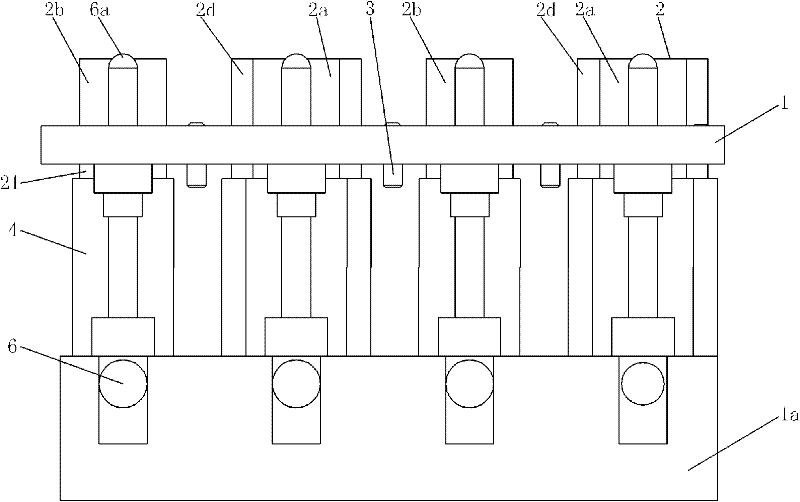

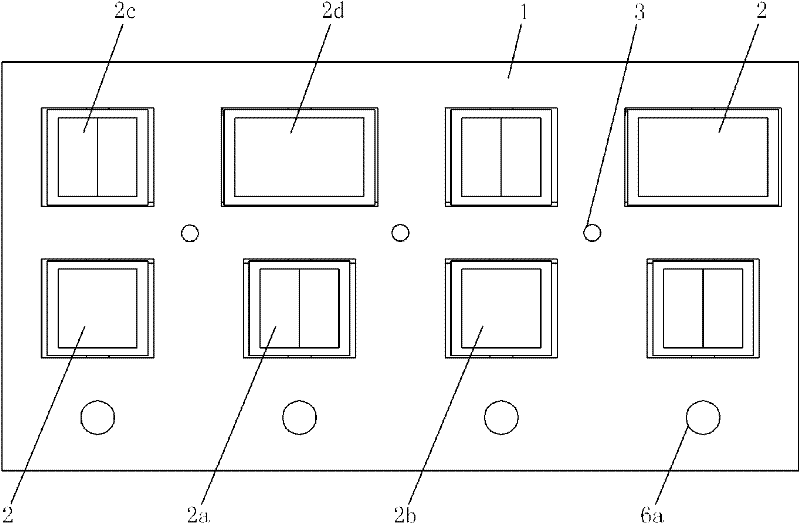

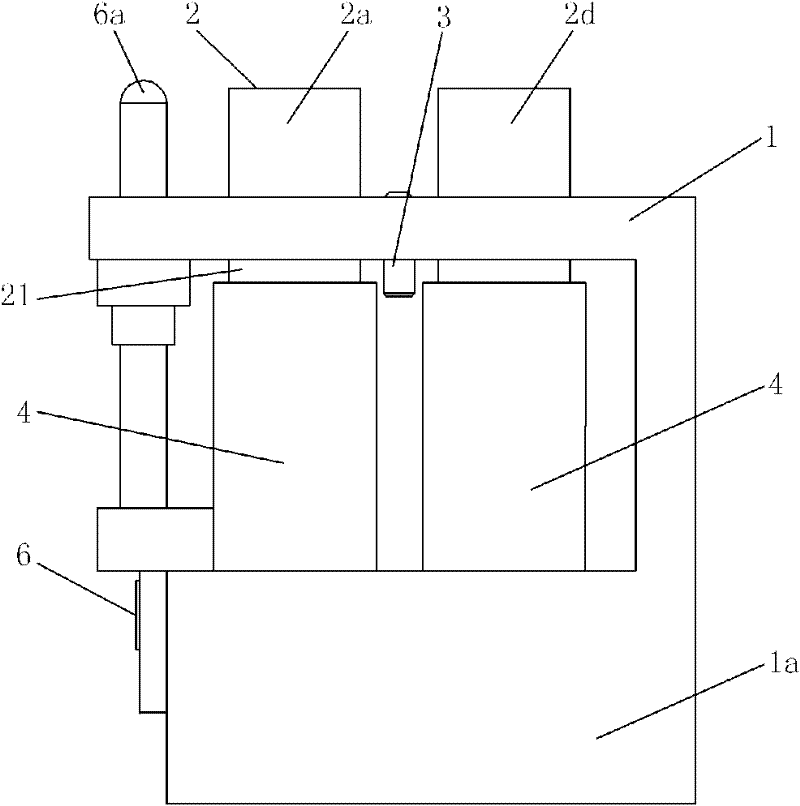

[0021] figure 1 , 2 , 3 shows that a specific embodiment of the present invention is: an adaptive ultrasonic testing device for on-line flaw detection of train wheels, including a probe base 1, a spray hole array 3 on the probe base 1, and a plurality of probe bases clamped on the probe base 1. The probe array formed by the ultrasonic probe, the control device connected to the probe array and the spray hole array 3, is characterized in that:

[0022] The probe array is composed of more than two horizontal rows or vertical inner and outer columns of probes 2, and its specific arrangement is as follows: the inner column is alternately arranged with double-crystal probes 2a and small-angle single-crystal probes 2b, and the outer column is composed of dual-crystal probes 2a. Probes 2c and large-angle single-crystal probes 2d are arranged alternately, and the inner row of dual-crystal probes 2a and the outer row of dual-crystal probes 2c are in different rows;

[0023] Probe base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com