Ladle automatic dumping and slag skimming anti-splash system and automatic slag skimming method

A ladle and slag removal technology, which is applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of molten steel splashing and hurting people in the production area, achieve high physical labor intensity, improve the cleanliness of slag removal, and improve The effect of slag cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

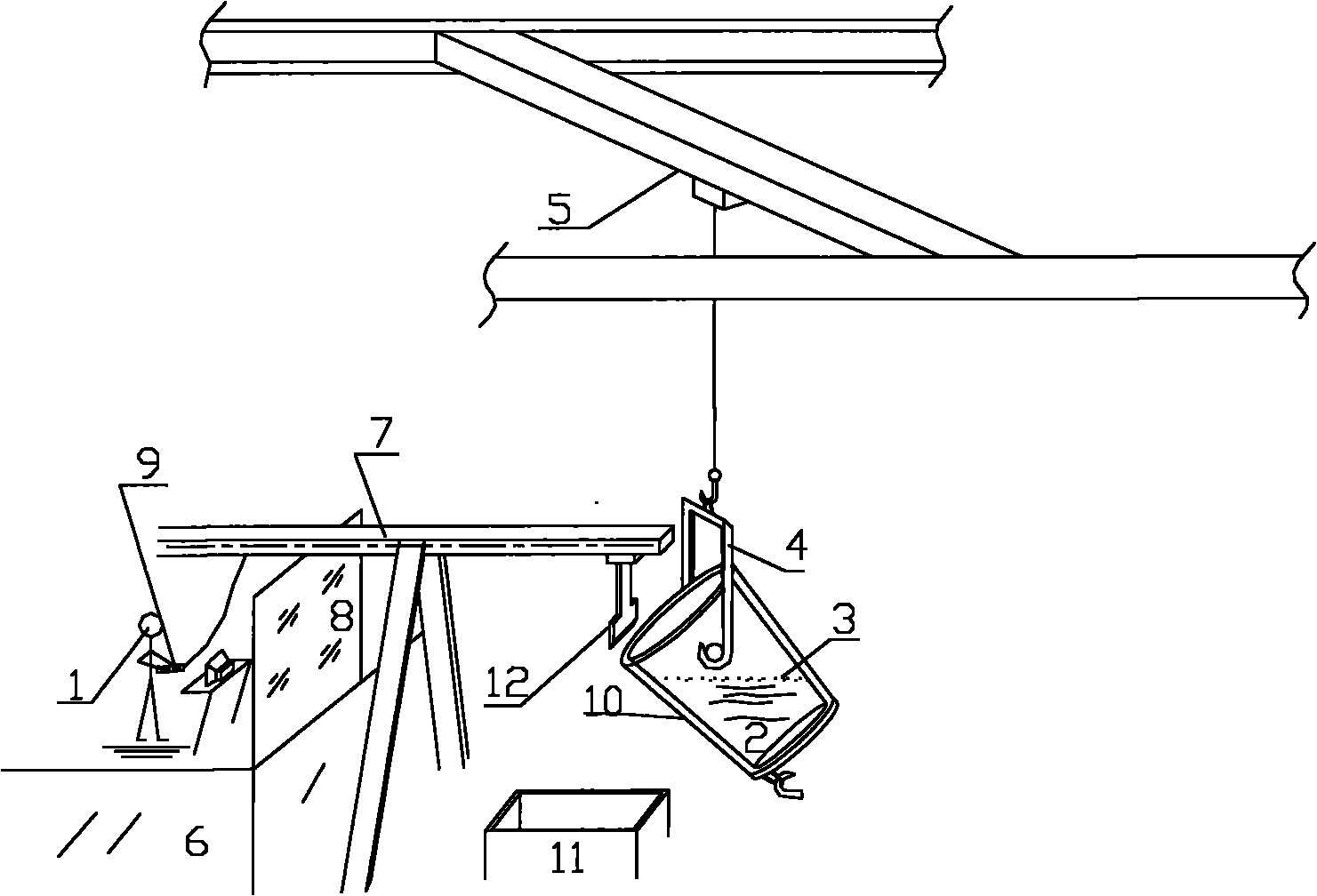

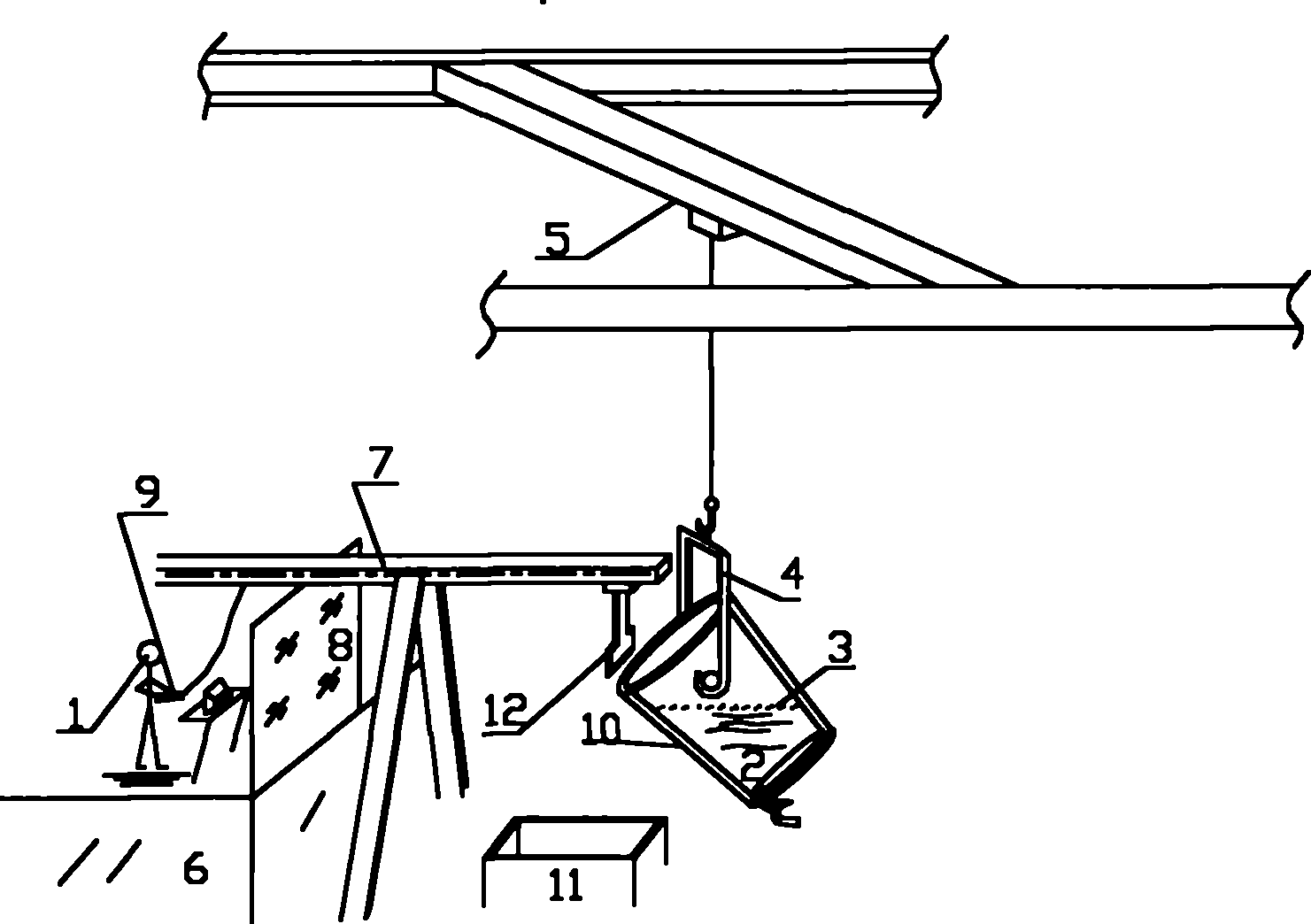

[0009] Embodiment 1: with reference to attached figure 1 . A ladle automatic dumping and slag removal anti-splash system, which includes a slag removal ladle 11, a steel ladle 10 suspended on a crane 5 through a gantry 4 and located above the slag removal ladle 11, and a splash guard is provided in front of the slag removal ladle 11 A gantry rake 7 is arranged above the plate 8 and the splash guard 8 , and the gantry rake 7 is connected to and controlled by the controller 9 . Whether it is a portal type gantry harrow or a suspended gantry harrow, its working principle and basic structure are similar to those of a gantry crane, and the gantry frame in the suspended gantry harrow 7 is suspended and fixed. The key difference is that the gantry harrow 7 is a portal type gantry harrow or a suspended gantry harrow and is rigidly connected to the driving mechanism. This is one of the essential differences between the gantry harrow 7 and the gantry crane; the second essential differe...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the controller 9 is a wireless controller and performs data exchange with the wireless transceiver in the gantry harrow 7 through a wireless communication channel, and manually wirelessly controls the working state of the gantry harrow 7 . Controlled by wireless controller

Embodiment 3

[0011] Embodiment 3: On the basis of Embodiment 1, the controller 9 is a program controller and instructs the gantry rake 7 to automatically remove slag through program instructions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com