Reladling mechanism and reladling method of ladle

A technology of ladle and ladle inversion, which is applied in the field of ladle inversion mechanism manufacturing, which can solve problems such as inability to realize ladle inversion, and achieve the effect of reducing investment cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

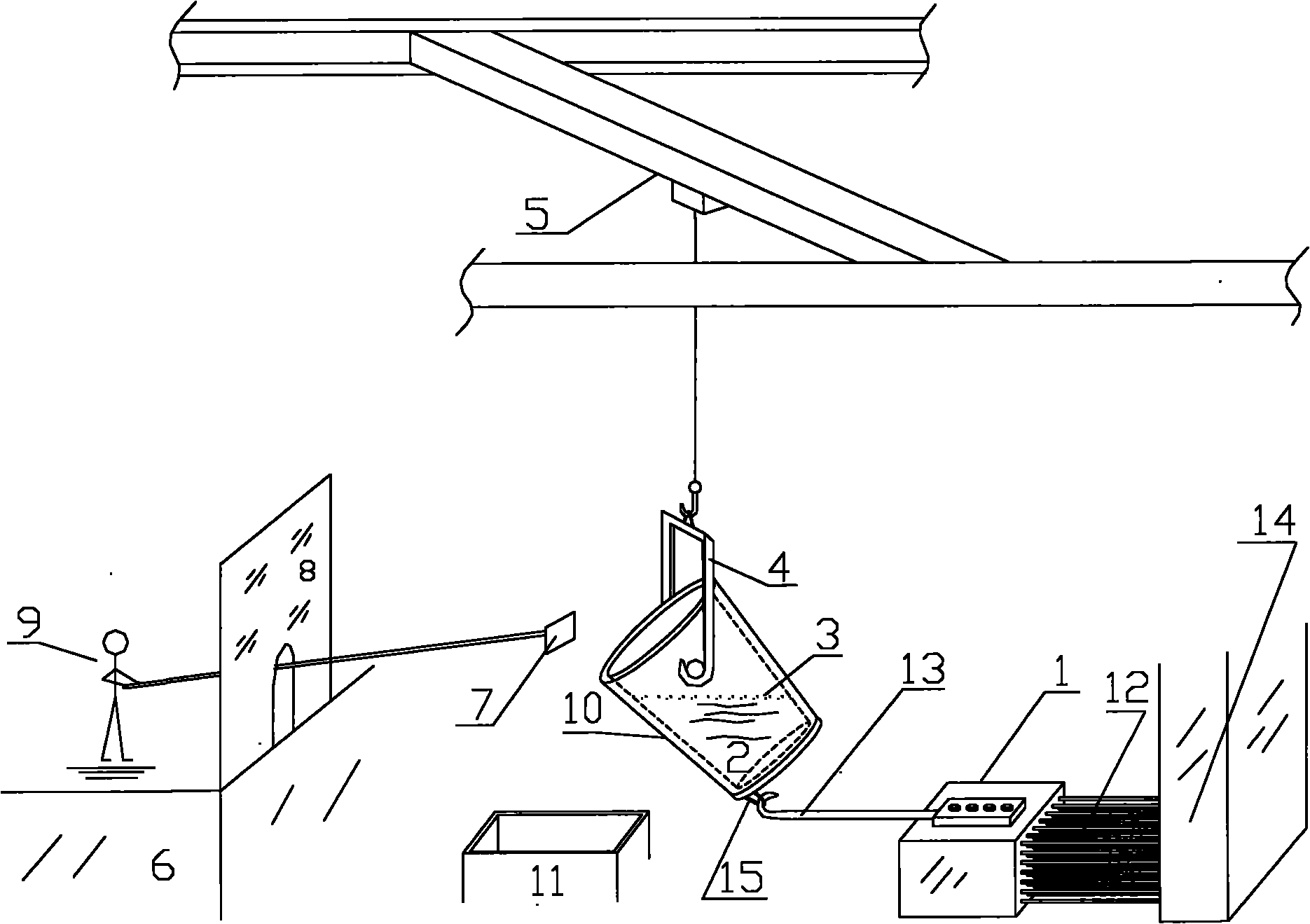

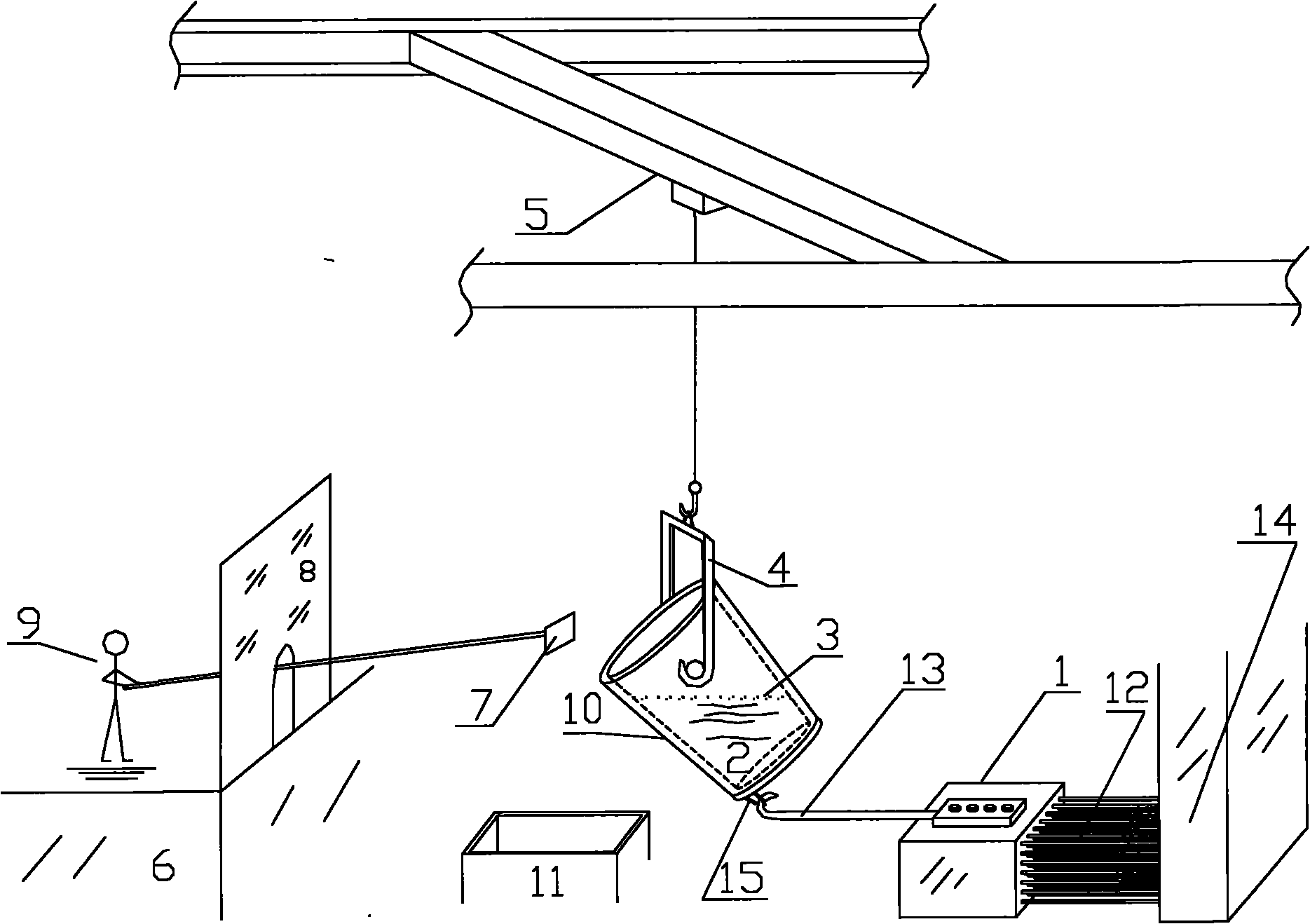

[0009] Embodiment 1: with reference to attached figure 1 . A ladle reversing mechanism, the ladle 10 is hung on the crane 5 through the gantry 4 and is located above the slag removal bag 11, the slag removal bag 11 is provided with a splash guard 8 at the front, and a fixed hook pier 1 at the rear. A ladle hook 13 is fixed on the fixed hook pier 1, and the fixed hook pier 1 is connected with a positioning pier 14 through several steel bars 12;

[0010] There is a hole 8 for the slag removal tool 7 to pass through the splash guard 8, and the splash guard 8 is a toughened transparent glass plate, which is resistant to high temperature and has a good perspective effect. It is safe for the operator 1 , and easy to observe.

[0011] The hook body of the ladle hook 13 is suspended in the air on the fixed hook pier 1 and the hook head faces the slag removal bag 11, so as to facilitate cooperation with the shackle 15 at the bottom of the ladle.

Embodiment 2

[0012] Embodiment 2: On the basis of embodiment 1, a kind of ladle reversing method of ladle reversing mechanism is characterized in that: after the molten steel in the steelmaking furnace is poured into ladle 10, driving 5 hangs ladle 10 and uses After the shackle 15 at the bottom of the ladle 10 is hooked by the ladle hook 13 on the fixed ladle pier 1, the trolley 5 continues to move forward and makes the opening of the ladle 10 inclined, and the opening of the ladle is opposite to the opening of the slag removal ladle 11 along the downward direction. , the operator 9 stands at the front of the console 6, holds a slag rake 7 tool and passes through the hole 9 on the splash guard 8 to scrape the furnace layer 3 on the liquid surface of the molten steel 2 in the ladle 10 into the slag removal Pack of 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com