Single-side hub type energy-saving wheel device

A wheel and hub type technology is applied in the field of single-side hub type energy-saving wheel devices, which can solve the problems of narrow application range and complex system structure, and achieve the effect of convenient control and operation, and improving operation rationality and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

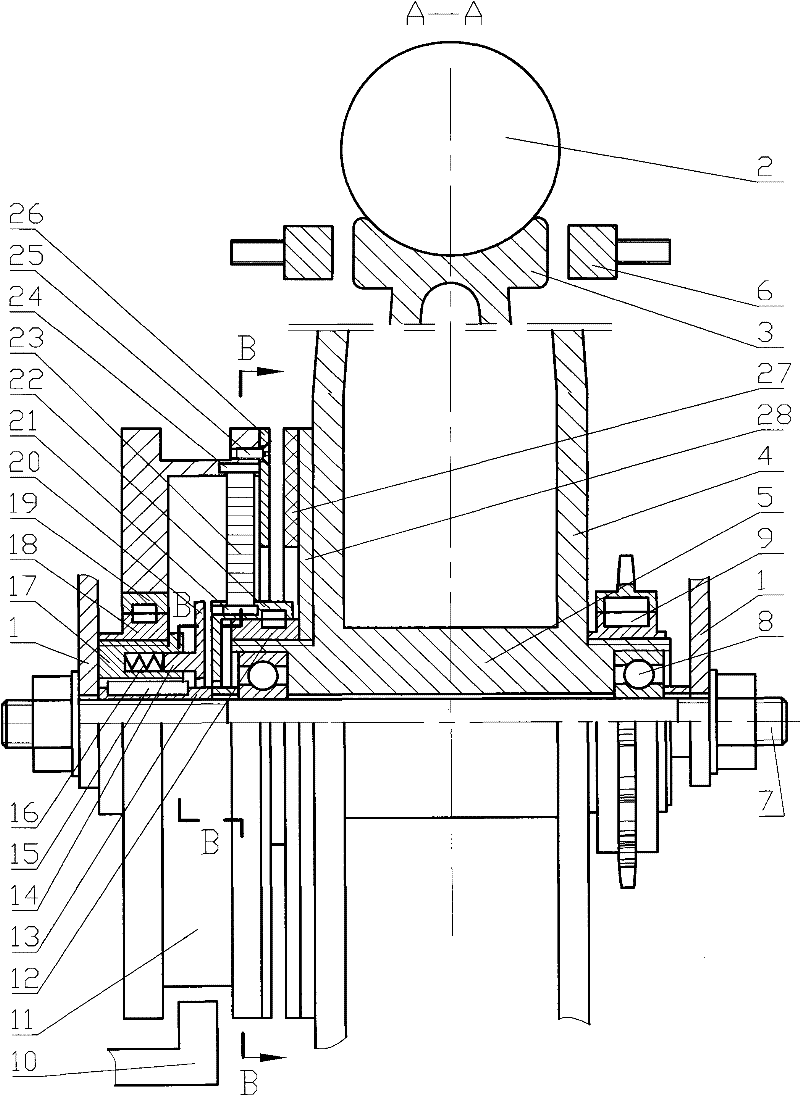

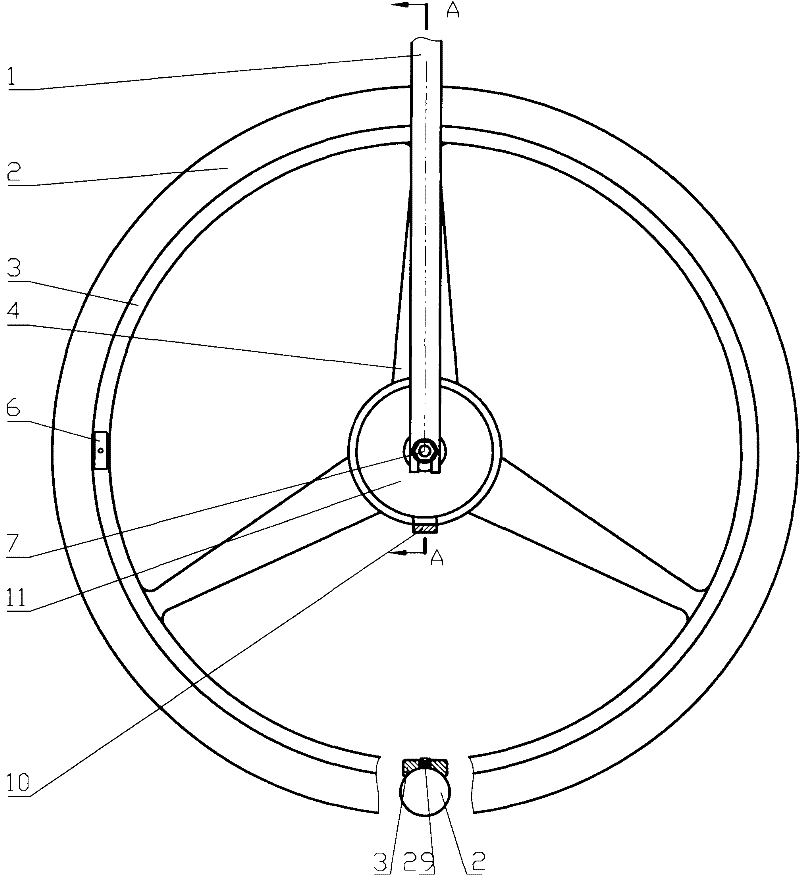

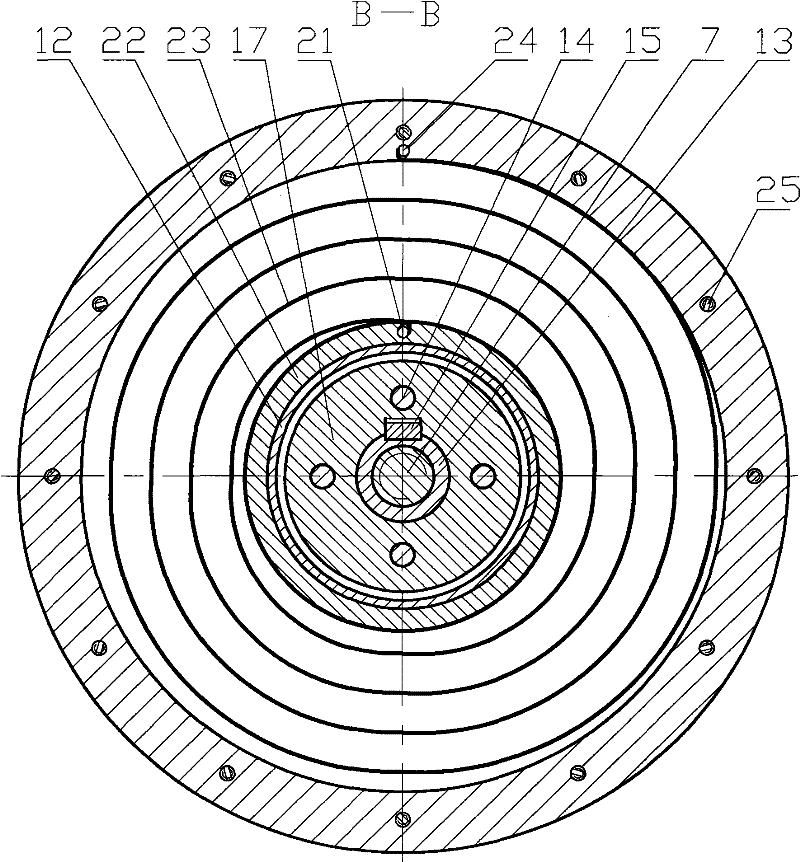

[0013] exist figure 1 and figure 2 and image 3 Middle: shows the overall structure of the present invention, and is also an embodiment diagram when the wheel rotates normally, consisting of a wheel body mechanism, an energy conversion mechanism and a control mechanism. The wheel is a centrally symmetrical structure, the spokes (4) are 3 or more than 3, evenly distributed, and have the same structure and shape; the wheel rim (3) is covered with a tire (2), and the tire (2) is provided with a valve Mouth (29); Wheel rim (3), wheel spoke (4), wheel hub (5) are one body, and bearing (8) is respectively installed in the left and right sides of wheel hub (5), and axle (7) is installed in bearing (8) , the axle (7) is fixed on the wheel frame (1), and the wheel brake (6) is placed on both sides of the wheel rim (3). The energy conversion mechanism is arranged on the left wheel hub (5), and the outer cylindrical surface of the left wheel hub (5) is equipped with a right one-way b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com