Water flow measurement sensory control assembly

A technology of sensor control and water flow meter, which is applied in flow control of electric devices, volume measurement, liquid/fluid solid measurement, etc. It can solve problems such as multi-space, forced demolition cannot be monitored in time, and construction time is prolonged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

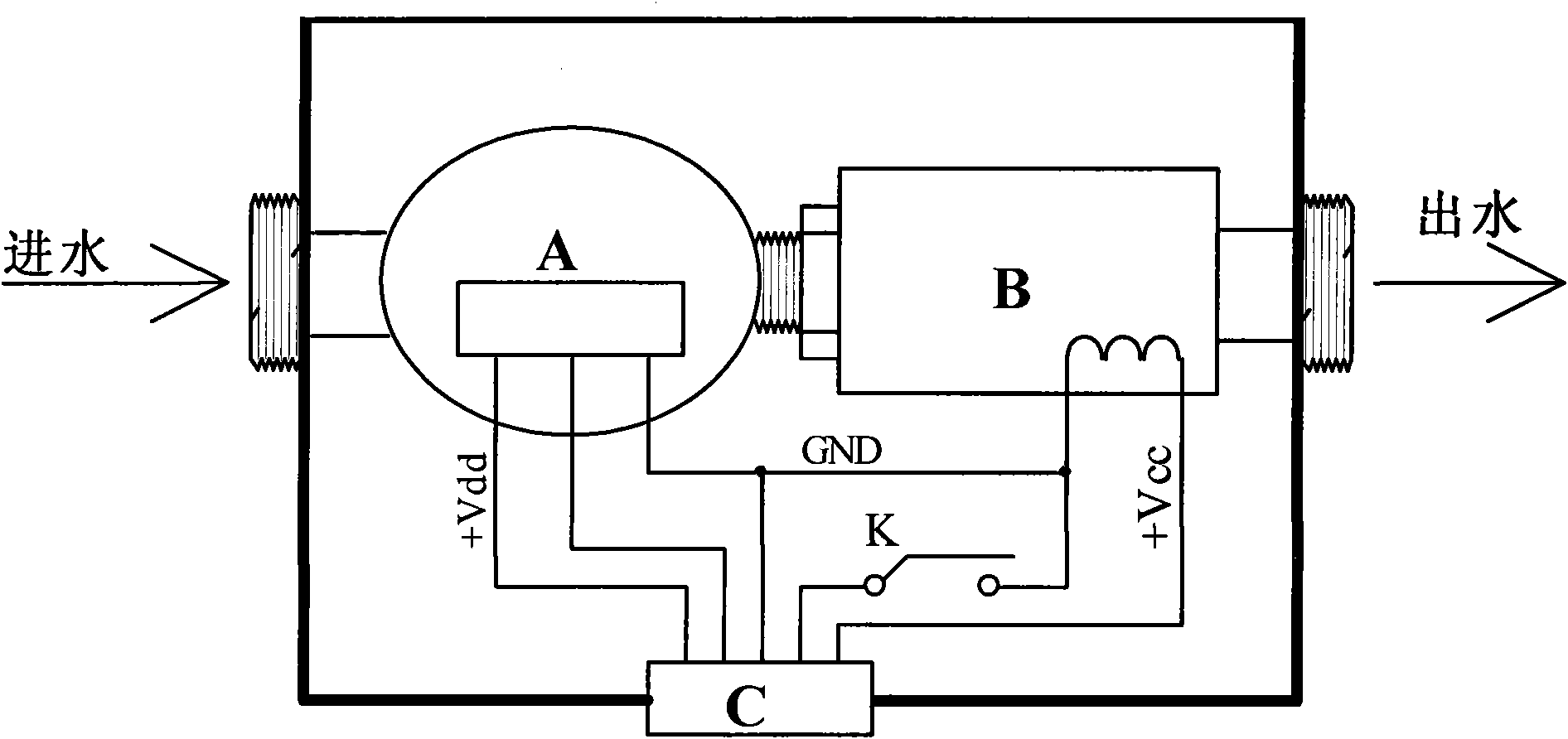

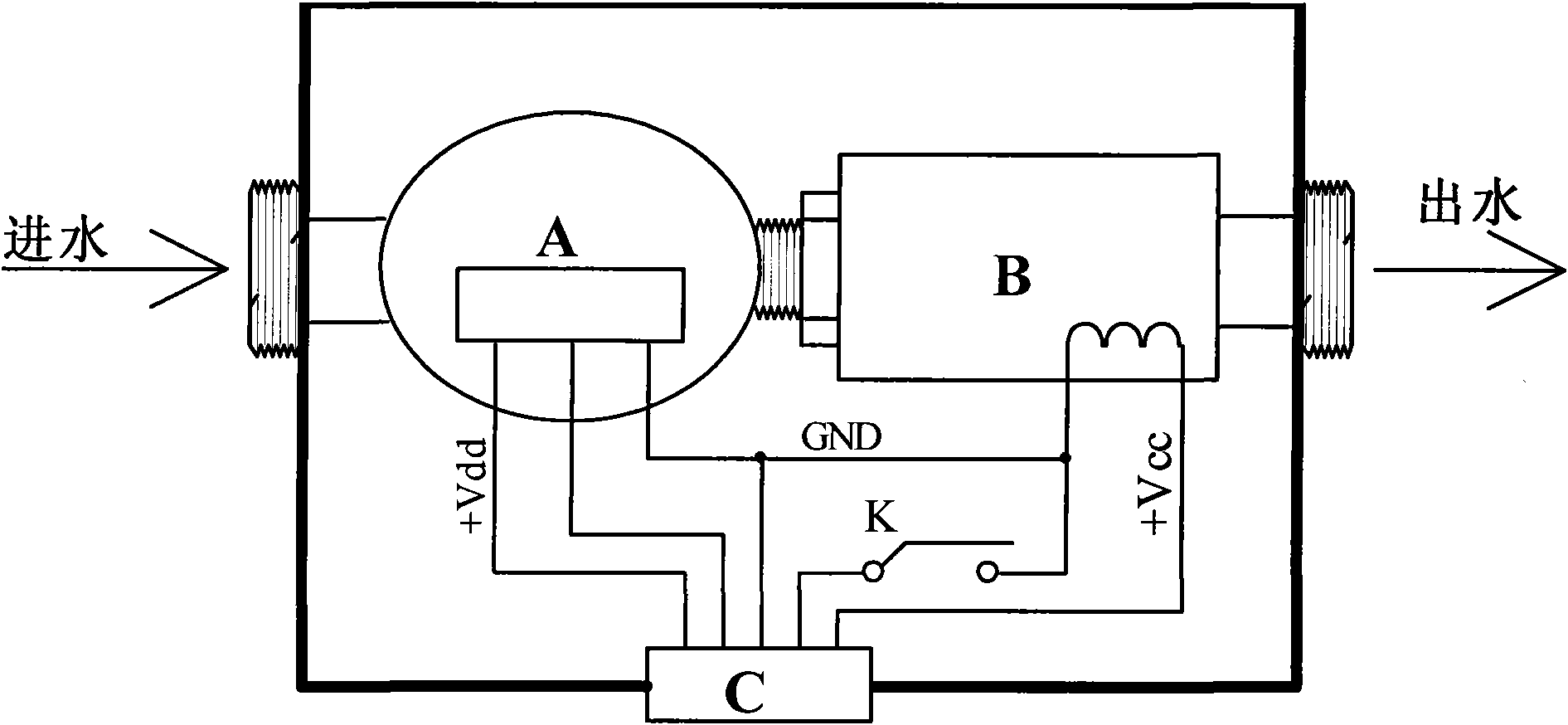

[0007] Specific implementation method: the water flow measurement sensor control assembly is to connect the electronic water flow meter A with the electronic control valve B, and put them into a casing together. The casing of the water flow measurement sensor control assembly is divided into an upper casing and an upper casing. There are two parts of the lower shell, fix an electronic button switch K on the lower shell with the button facing up, make a small pillar in the upper shell, the position and height of the pillar are: when the upper and lower shells are combined, the pillar should be pushed to On the button of the electronic button switch and make the electronic button switch just close; one contact of the electronic button switch K is connected to the ground wire of the electric control valve, and the other contact is connected to the power supply line and signal line of the electronic water flow meter and the electric control valve. The ground wires are uniformly twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com