Rotary type push switch

A rotary and switch technology, which is applied in the direction of electric switches, building structure supports, electrical components, etc., can solve the problems of inability to ensure stable contacts, easy wear of contact protrusions, and inability to ensure contact performance, etc., to achieve excellent contact Point performance, excellent operation feeling, and the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

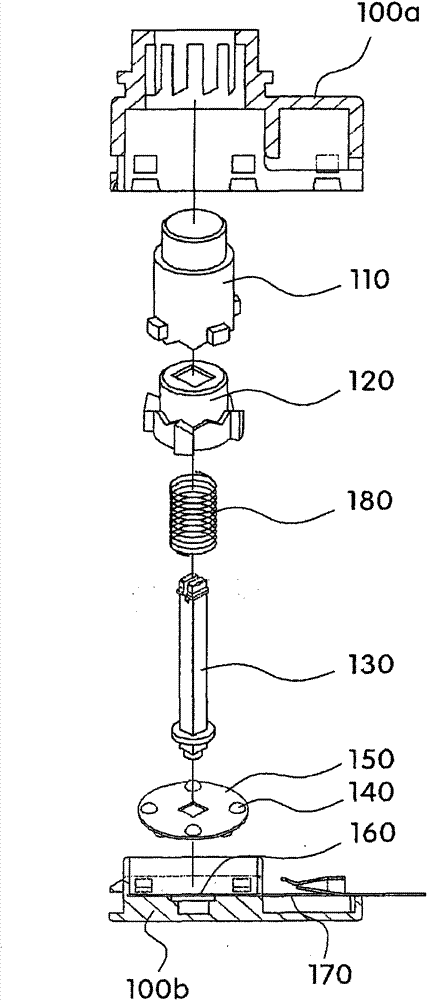

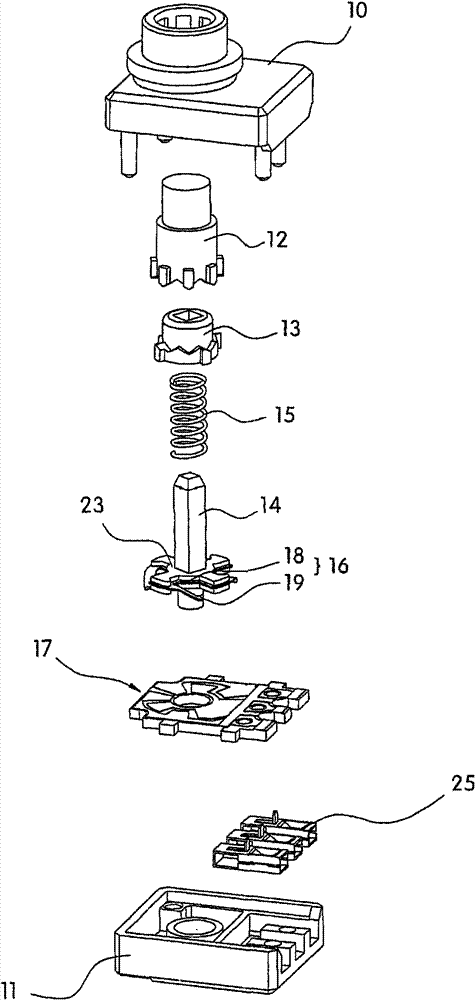

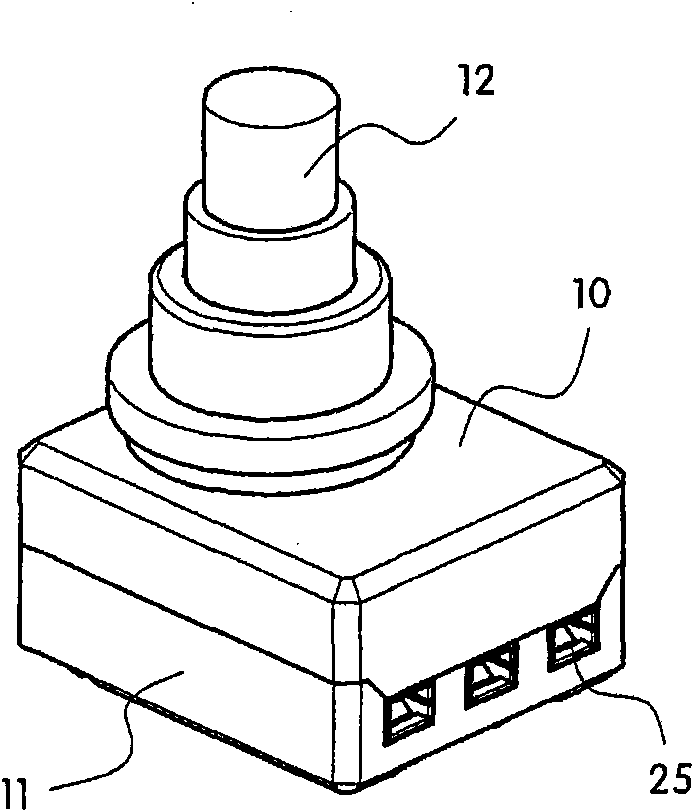

[0042] figure 2 , Figure 3a and Figure 3b It is a schematic diagram of a rotary push switch according to an embodiment of the present invention.

[0043] Such as figure 2 , Figure 3a and Figure 3b As shown, the above-mentioned rotary push switch includes: upper / lower shells 10, 11, which accommodate other components by assembling up and down; button 12, as a component contained in the above-mentioned upper shell 10, for the user to complete the operation; The tube 13 completes the cam action through the operation of the above-mentioned button 12; the movable terminal 16 and the shaft 14 rotate intermittently through the operation of the above-mentioned solenoid 13 and forms a contact with the fixed terminal 17; the spring 15 is used to restore the above-mentioned button 12; and The fixed terminal 17 is a component accommodate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com