Equipment detection method and equipment

An equipment detection and equipment technology, applied in the field of communication, can solve the problems of broken pins of the interface board and the main control board, loss of manpower and material resources for troubleshooting, and the cause of the failure is not easily exposed, etc., and achieves the effect of saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

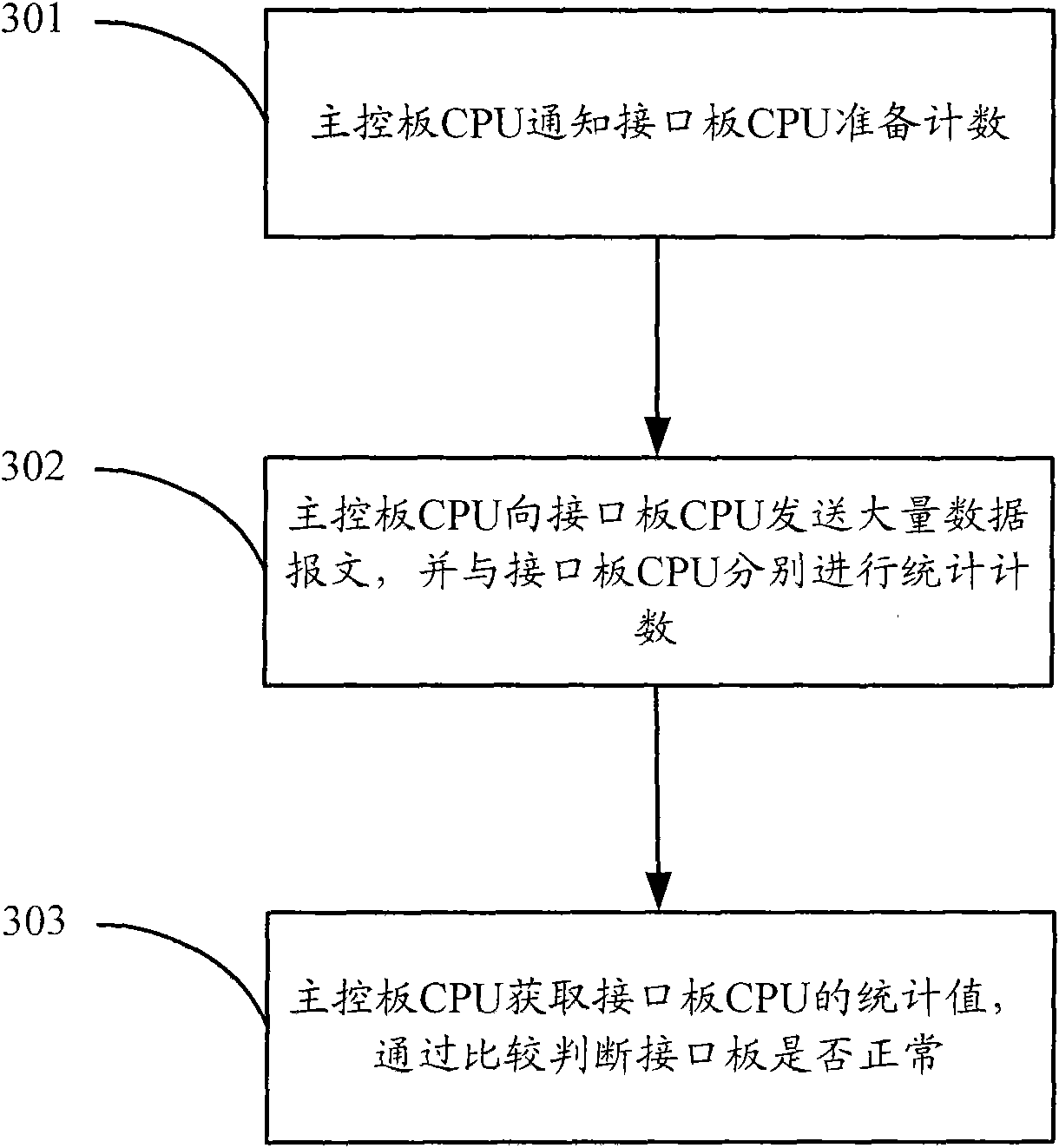

[0046] The core idea of the present invention is: configure the detection message to perform hardware detection on the control level, data level and detection level of the device, so as to ensure that the connection between the main control board and the interface board of the device is normally connected.

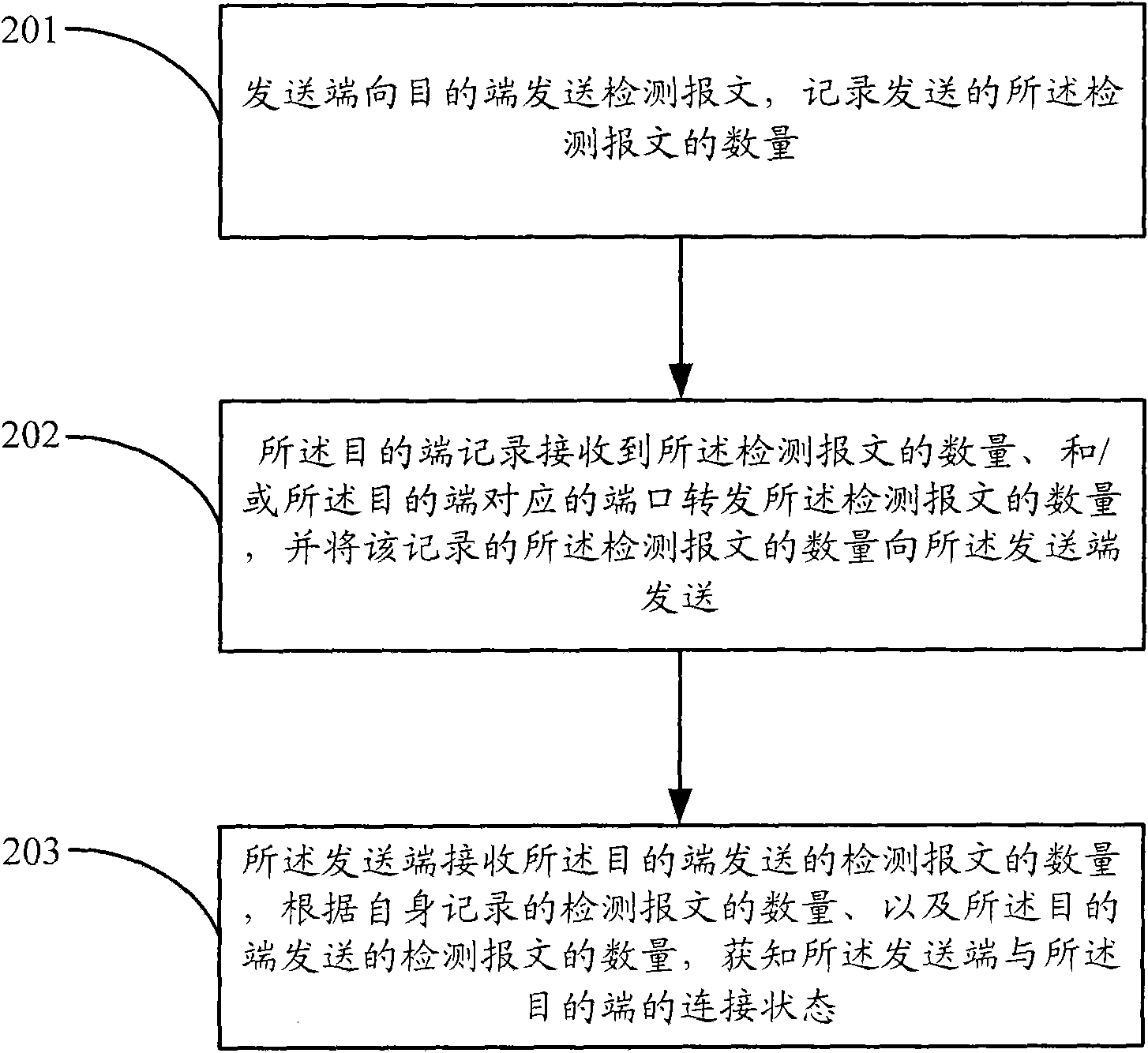

[0047] The invention provides a device detection method, which is applied to a device including a main control board and an interface board. Check the connection status of the software, such as figure 2 As shown, the method further includes:

[0048] Step 201, the sending end sends detection packets to the destination end, and records the number of detection packets sent;

[0049] Step 202, the destination end records the number of detection packets received and / or the number of detection packets forwarded by the port corresponding to the destination end, and sends the recorded number of detection packets to The sending end sends;

[0050]Step 203, the sending end re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com