High thermal conductivity electrode substrate

A thermal conductivity and substrate technology, applied in battery electrodes, circuits, fuel cells, etc., can solve problems such as difficulty in thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

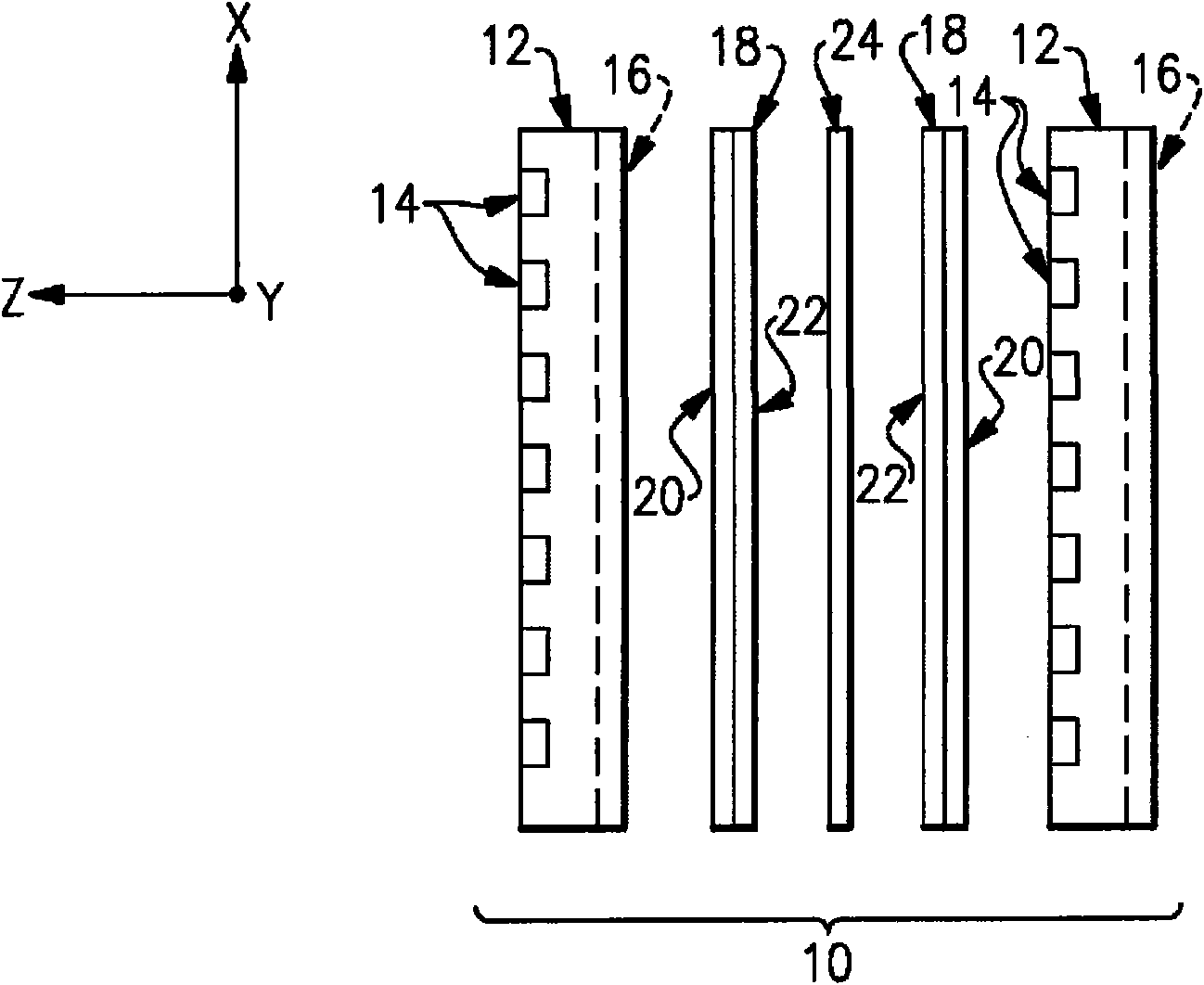

[0012] exist figure 1 An exemplary fuel cell 10 is schematically shown in . A plurality of batteries 10 are arranged adjacent to each other in the Z direction to form a stack (in figure 1 The Y direction is not shown). The fuel cell 10 includes a gas separator 12 having a fuel passage 14 arranged on one side and an oxidant passage 16 arranged on the opposite side. For one type of exemplary gas separator 12, fuel passage 14 and oxidant passage 16 are arranged orthogonally with respect to each other to convey hydrogen-rich fuel and air, respectively. Electrodes 18 are disposed on either side of electrolyte layer 24 and adjacent to gas separator 12 . The components of fuel cell 10 operate in a known manner. In an exemplary embodiment, electrode 18 includes a substrate 20 and a catalyst 22 .

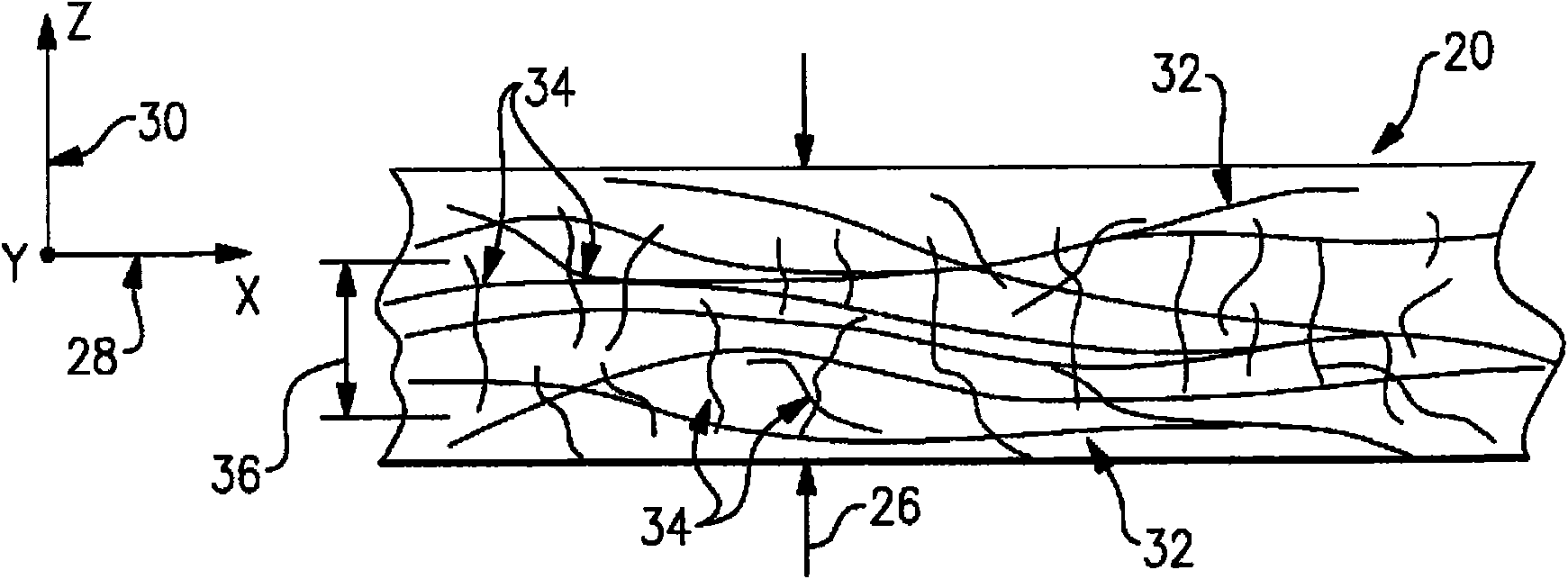

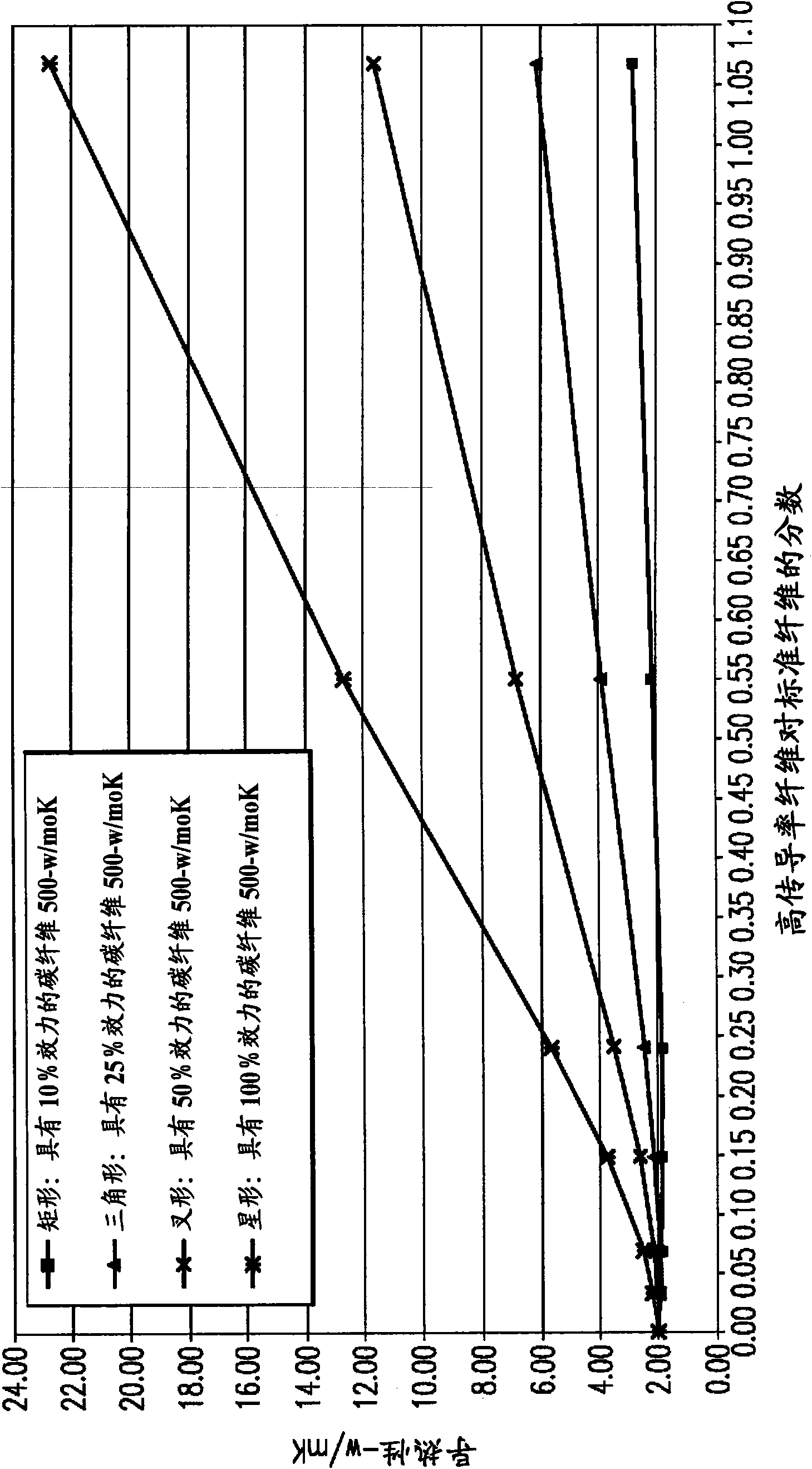

[0013] Typically, substrate 20 is composed of carbon fibers. The type and size of the carbon fibers are selected to provide various desired parameters of the substrate 20 . The exempl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com