Half carcass posture adjusting device on slaughtering production line

A technology for adjusting devices and production lines, applied to slaughtering, processed meat, meat processing equipment, etc., to achieve the effect of increasing laser burning time, reducing unstable time, and improving laser burning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] It should be noted that the front, rear, left, and right in the embodiments of the present invention are relative to the running direction of the slaughtering production line, that is, the slaughtering production line moves continuously from front to back, and the left and right sides are the operations of the slaughtering production line. side.

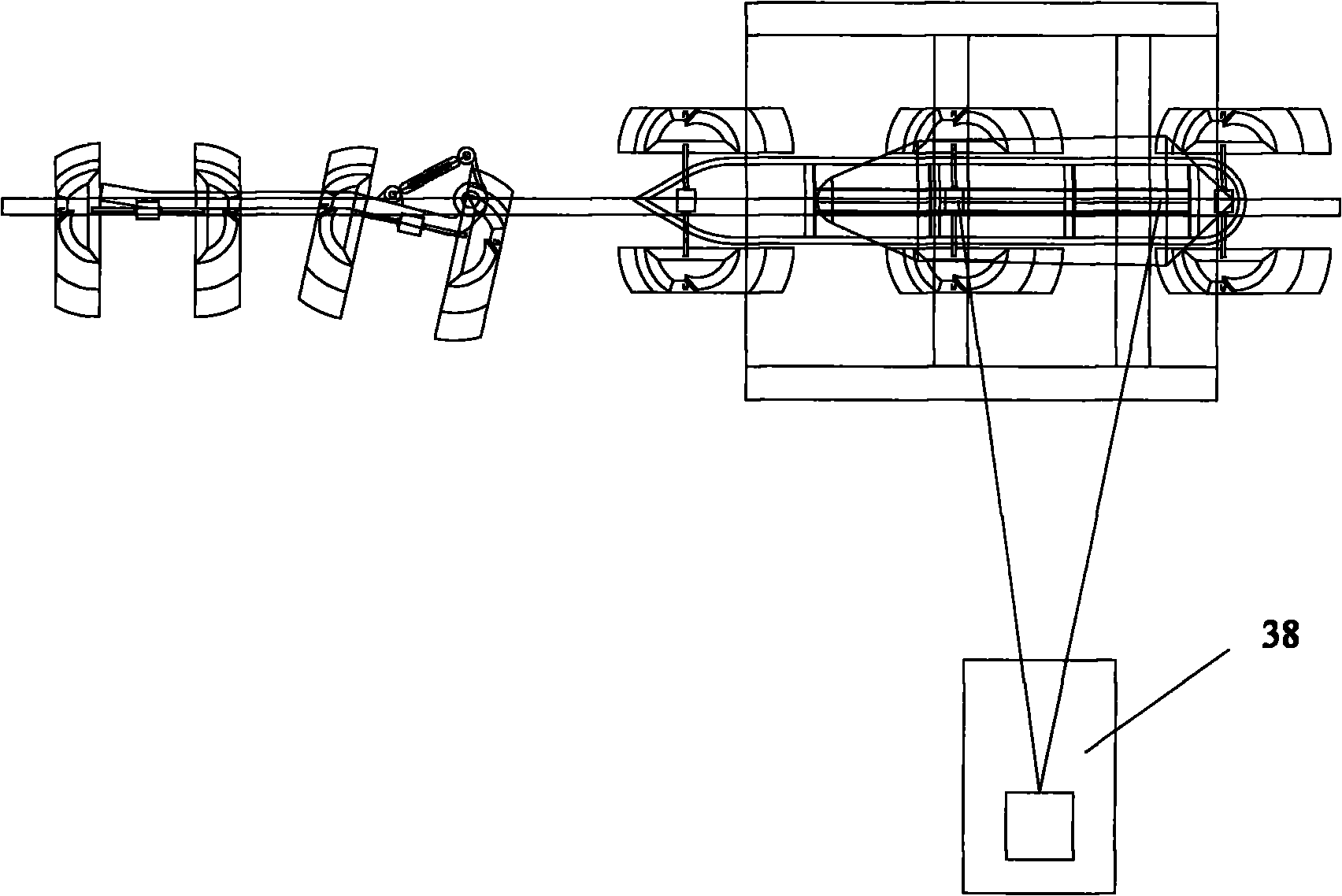

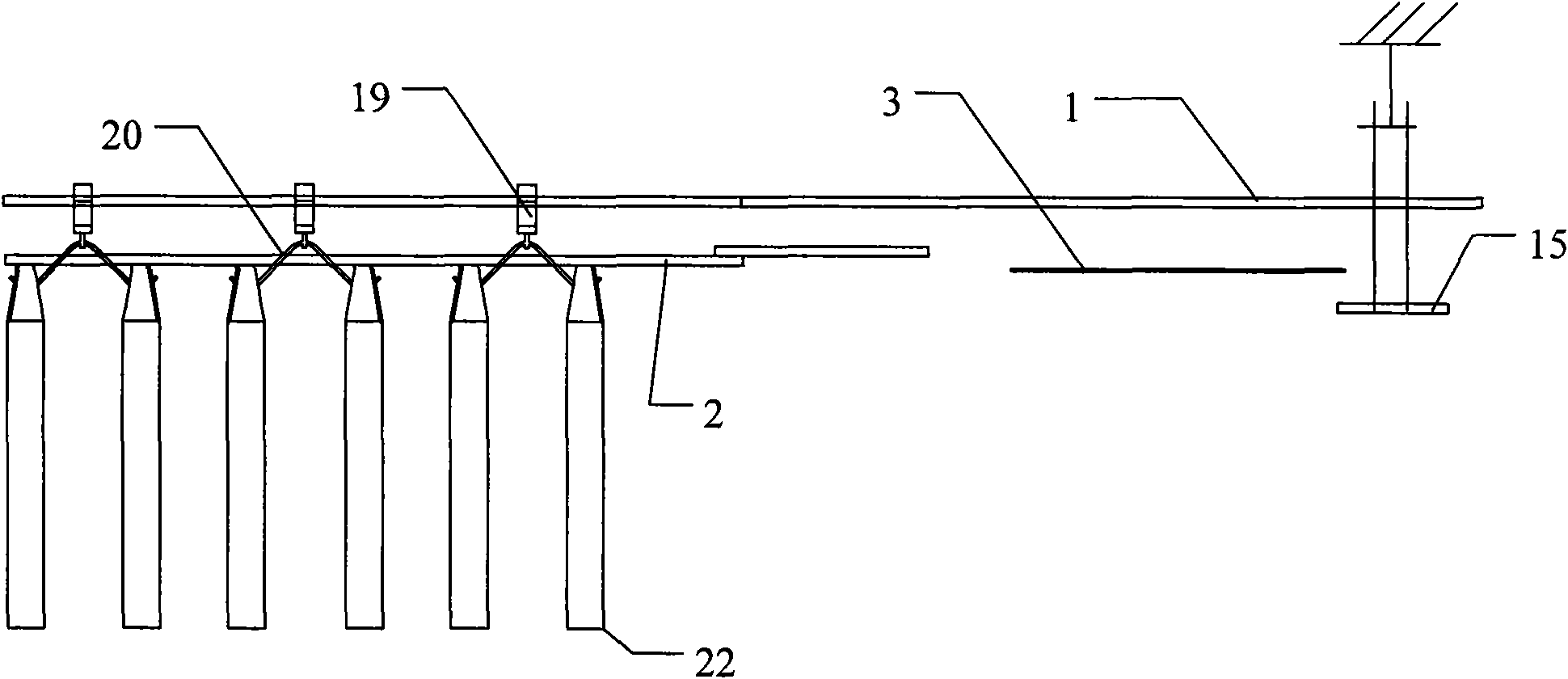

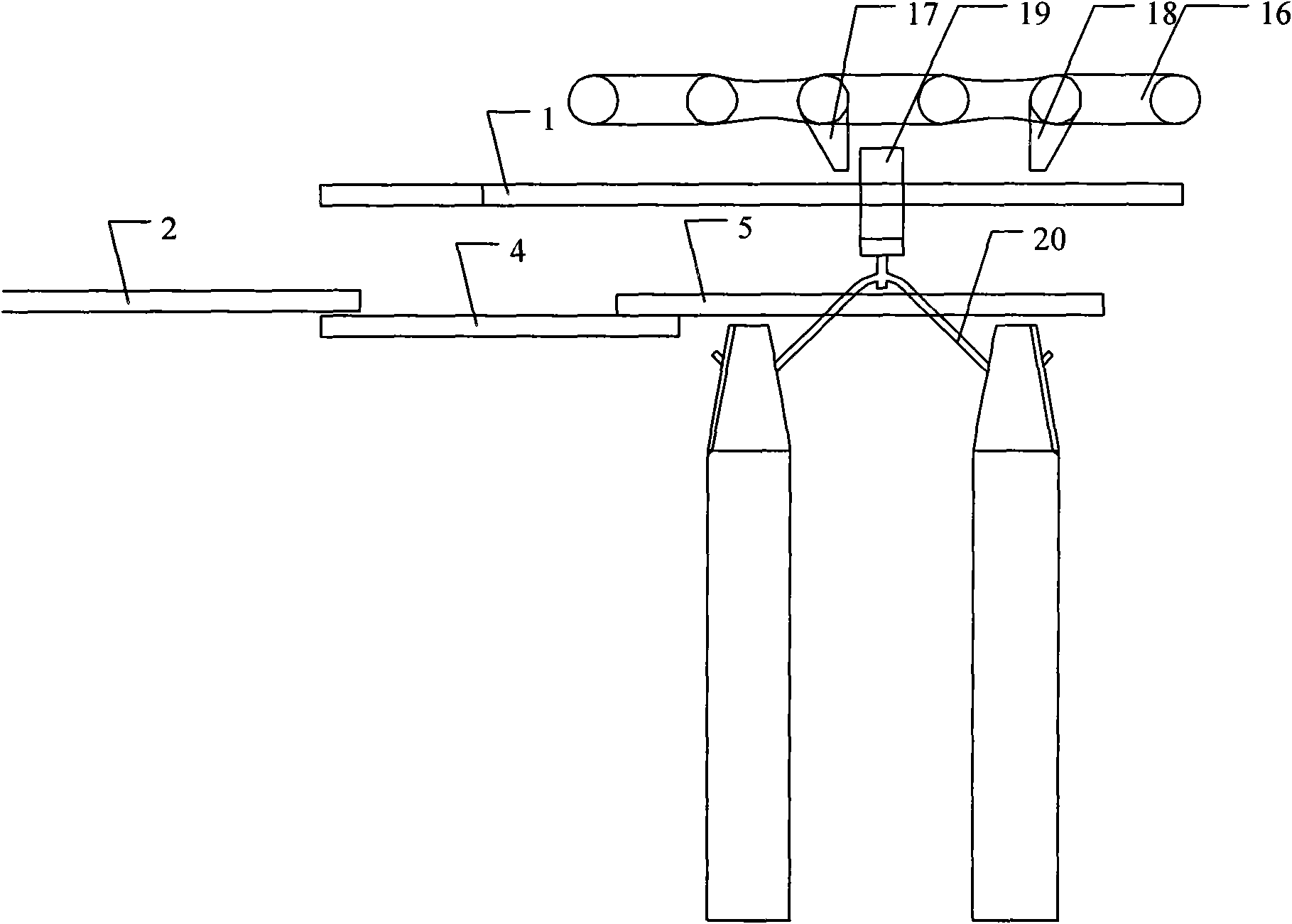

[0031] On the slaughtering production line, the pig carcass after slaughtering is usually divided into slices (that is, slices of pork, generally two pieces on the left and right) and hung on both sides of the hook, moving continuously along the main rail of the slaughtering production line. During the process, in order to meet the operator’s needs for inspection, quarantine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com