Hopper self-locking system

A hopper, self-locking technology, applied in the field of hopper self-locking system, can solve problems such as hopper damage, affecting production, and insufficient consideration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

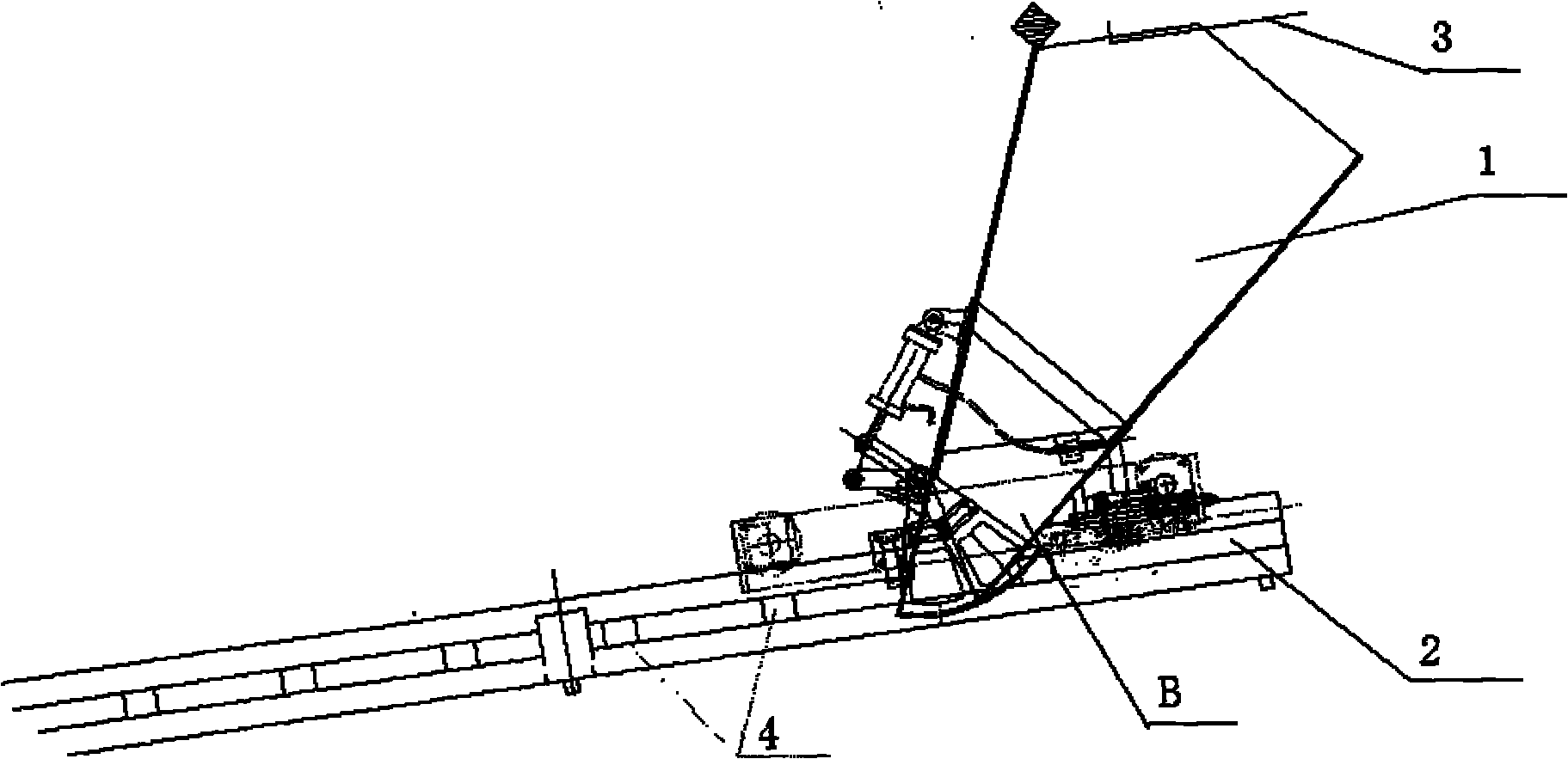

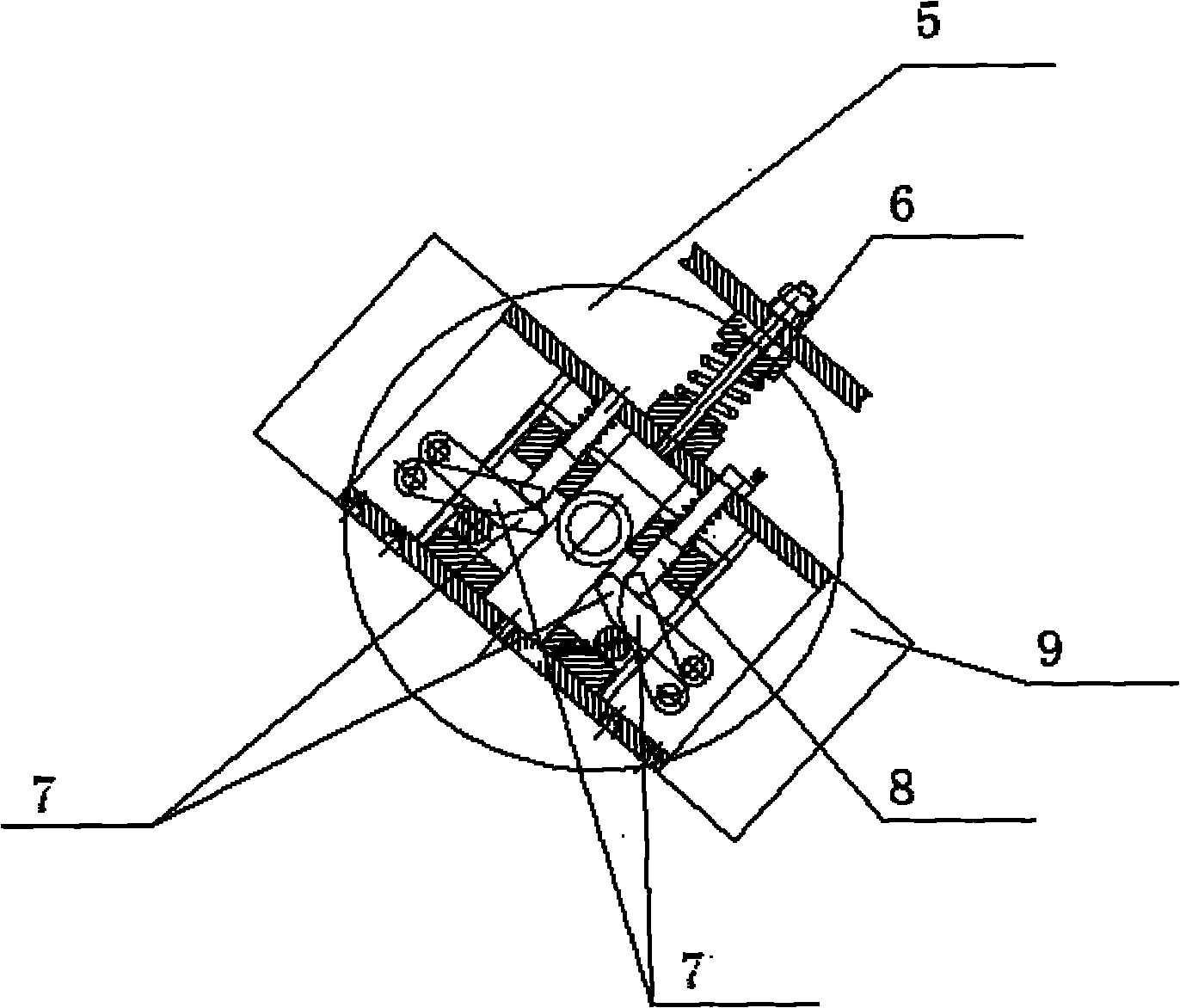

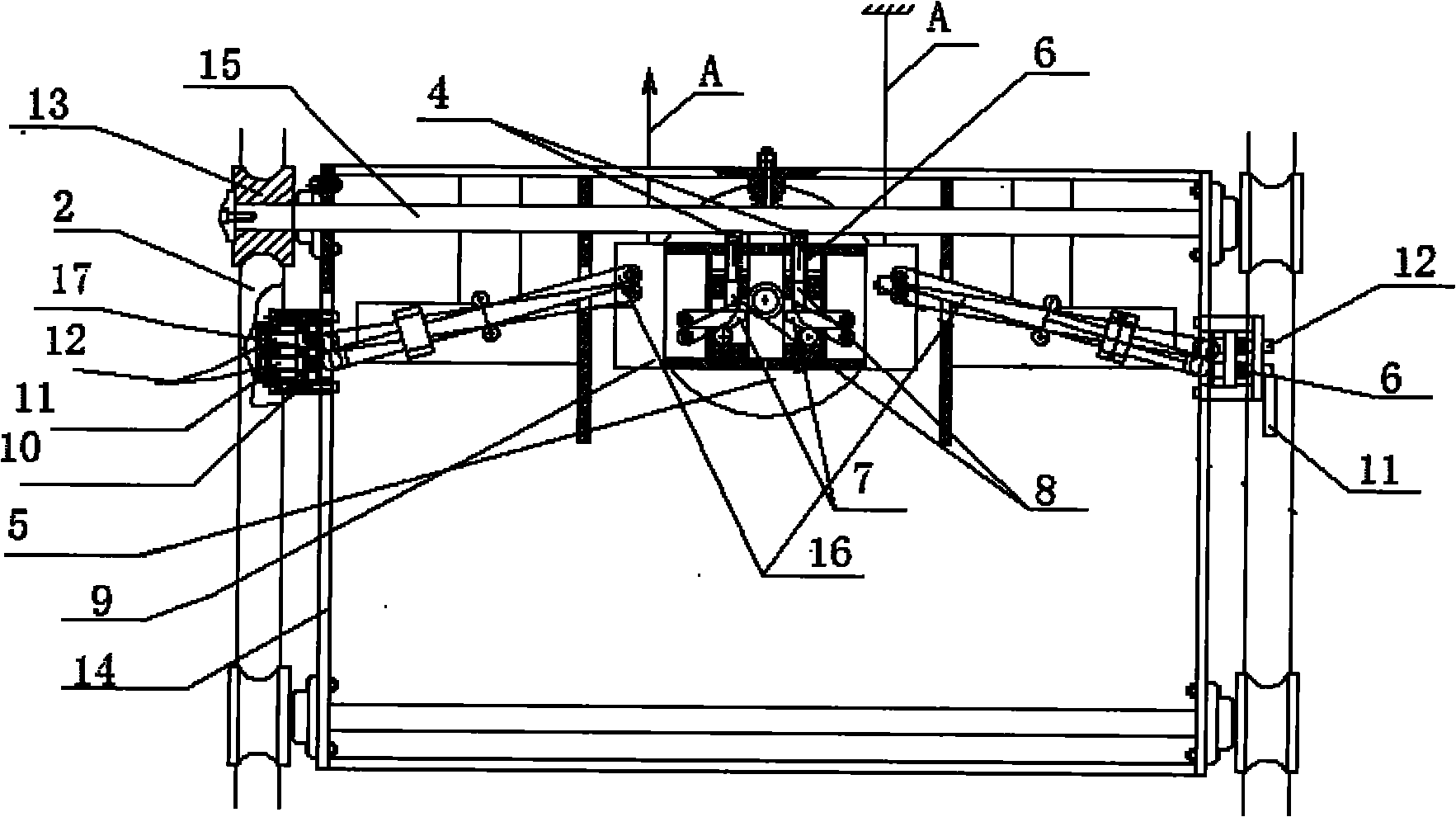

[0015] Such as figure 1 , figure 2 and image 3 As shown, the hopper self-locking system includes a hopper 1 and a track 2. A hopper cover 3 is installed on the hopper. A hopper seat B is installed at the bottom of the hopper 1. The hopper 1 is installed on the track 2. The hopper seat B includes a hopper frame 14. Two sets of hopper anti-slip devices 10 are welded on both sides of the frame 14, and the hopper anti-slip device 10 is provided with an anti-slip device body, a limiting block 11, a safety shaft 12, a safety shaft seat plate 17 and a return spring 6. The bit block 11 is arranged on the top of the safety shaft 12, and the limiting block 11 is the connecting plate of the upper and lower pipe beams on the track. There is a pulley skateboard 9, a pulley 5 is fixed on the pulley skateboard 9, and a limit block 4, a push rod 7, a safety shaft 8 and a return spring 6 are also arranged on the pulley skateboard 9, and the stop block 4 is installed on the top of the safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com