Oil pump cover

An oil pump and cover technology, applied in the direction of pressure lubrication of lubricating pumps, can solve the problems affecting the normal operation of the engine, high oil gas content, affecting the accuracy of the main oil channel pressure, etc., to reduce the gas content and ensure normal operation. , to ensure the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

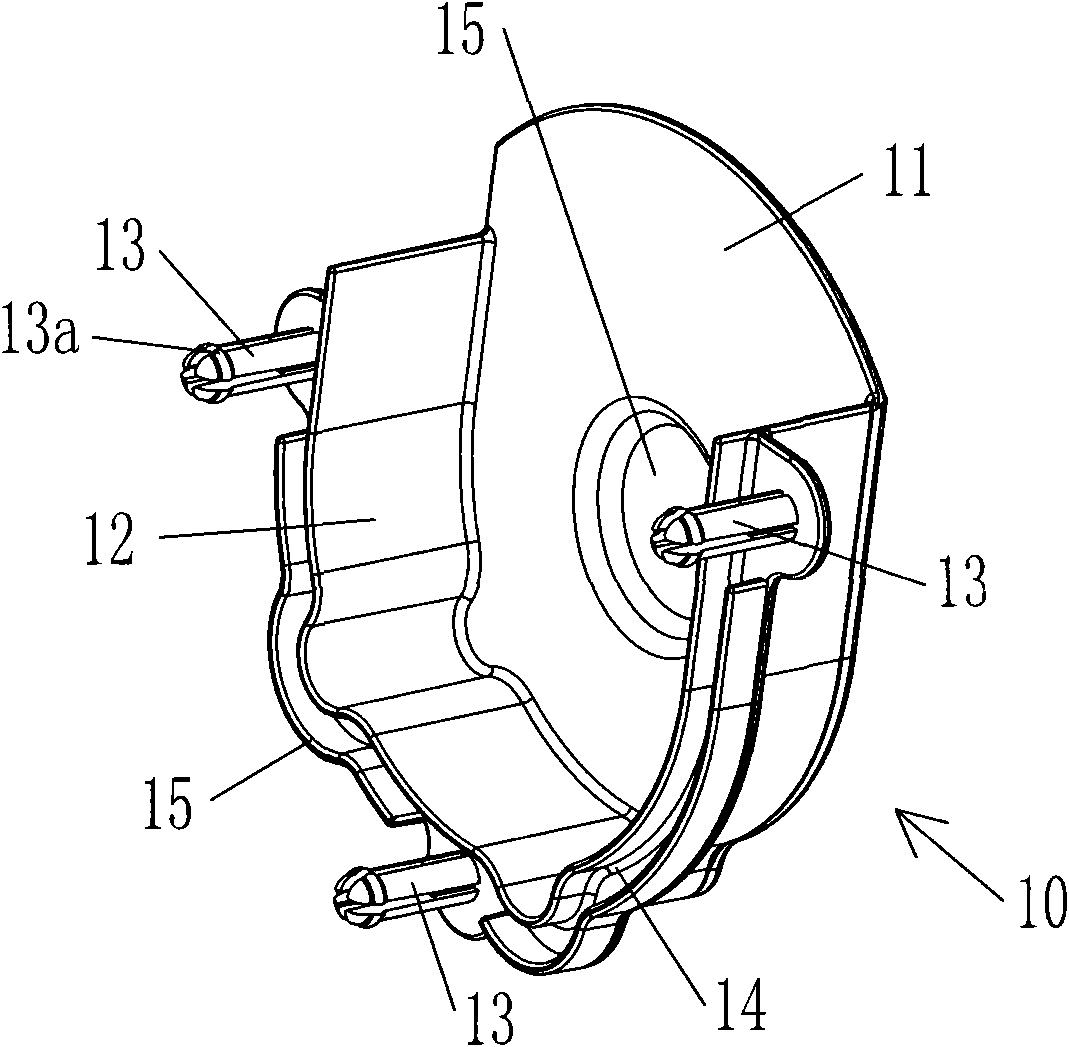

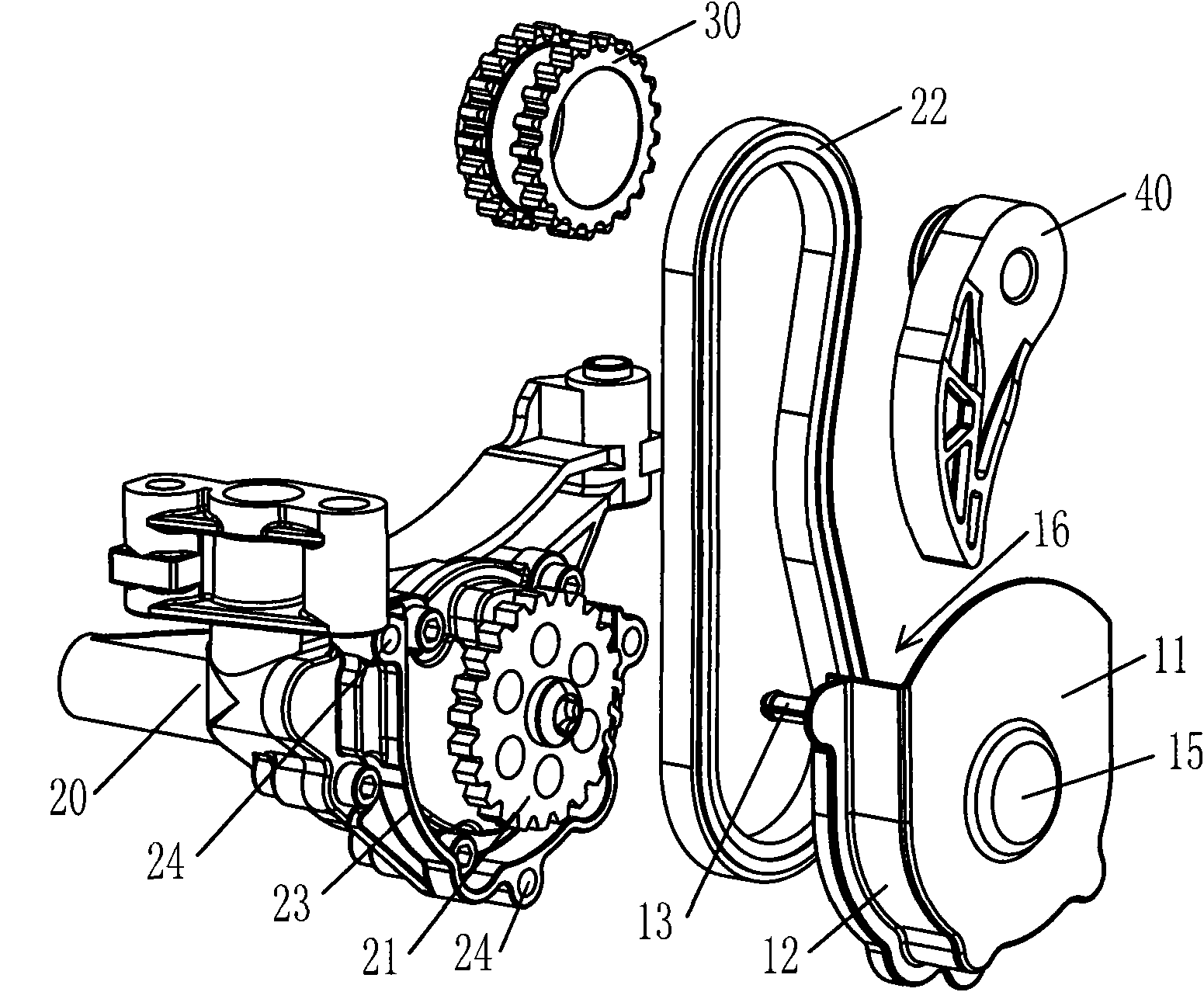

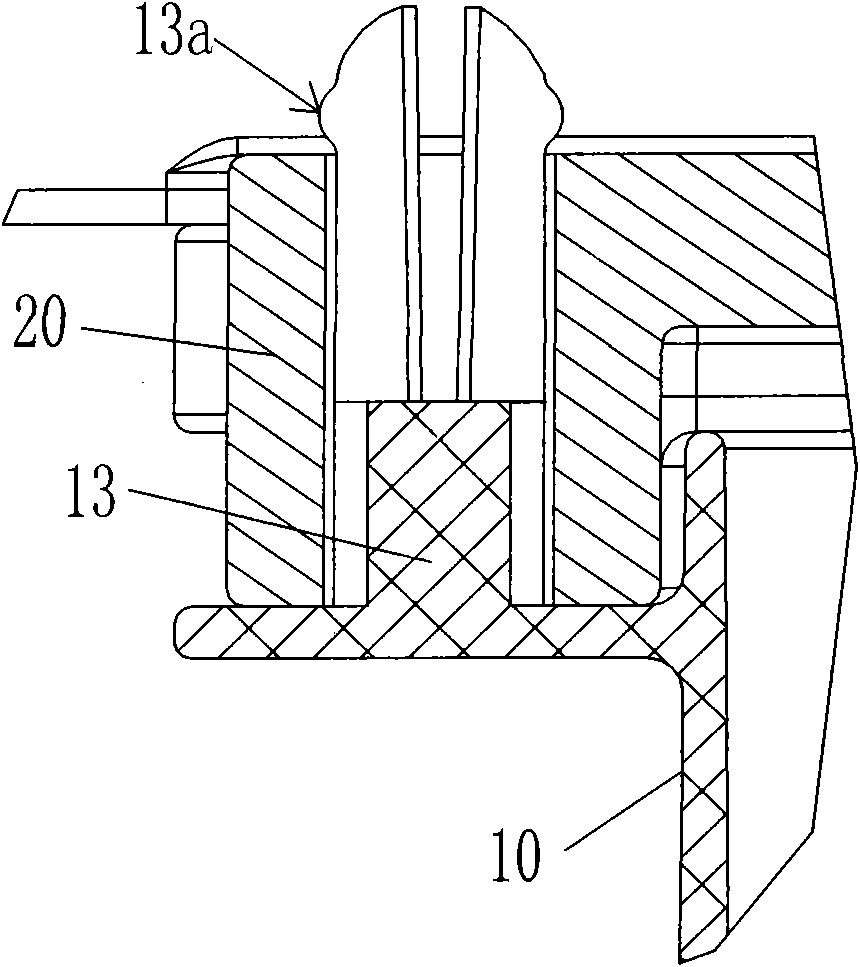

[0010] An oil pump cover, including a cover body 10, the overall weight is relatively light, the cover body 10 is covered on the oil pump 20, and the cover body 10 and the oil pump 20 are enclosed to accommodate the oil pump sprocket 21 and the slave machine. The cavity of the oil pump chain 22 bypassed on the oil pump sprocket 21, the joint of the cover body 10 and the oil pump 20 is sealed, and assembled together with the crankshaft timing sprocket 30 and the chain tensioner 40, the oil pump sprocket 21 and the crankshaft timing sprocket 30 drive the oil pump 20 to rotate under the action of the oil pump chain 22, as figure 1 , 2 shown.

[0011] to combine figure 1 , 2 , the cover body 10 includes a riser 11 , and the center of the riser 11 is provided with a protrusion 15 for covering the fixing bolt of the oil pump sprocket 21 . A sidewall 12 is extended along the direction perpendicular to the surface of the riser 11 at the edge of the riser 11 , and the peripheral pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com