Position precorrection device in ACF attaching equipment of flat-panel display

A flat-panel display and position calibration technology, which is applied to identification devices, instruments, nonlinear optics, etc., can solve problems such as short circuit, failure to guarantee the accuracy of ACF film application, and waste of ACF film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: the pre-calibration device in the flat panel display ACF sticking equipment

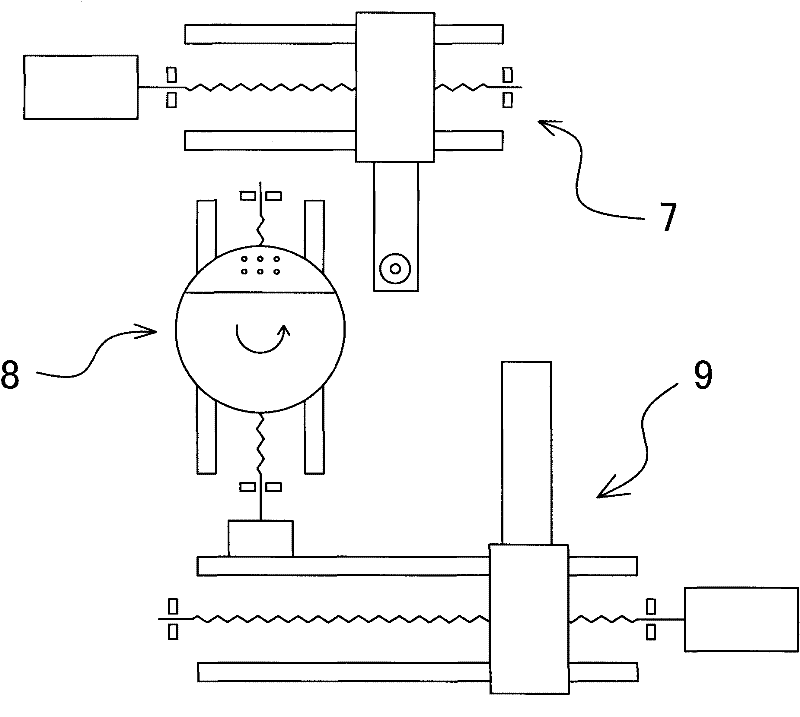

[0024] image 3 It is the schematic diagram of the pre-calibration device of the present invention, Figure 4 It is a perspective view of an embodiment of the pre-calibration device of the present invention. From image 3 and Figure 4 It can be seen from the figure that the pre-calibration device includes a camera mechanism 7 , a pre-calibration table top mechanism 8 and a transport mechanism 9 . The pre-calibration device may also include a mechanism arm (not shown) for transporting the LCD workpiece 46 to the suction table 44 . Since the mechanism arm is not essential to the present invention, it is omitted here to emphasize the key points.

[0025] The camera mechanism 7, the pre-school mechanism 8 and the transport mechanism 9 will be described emphatically below:

[0026] 1. Camera mechanism 7

[0027] Such as Figure 5As shown, the camera mechanism 7 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com