A protective film sticking equipment

A protective film and equipment technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as unguaranteed efficiency, offset tape sticking, and unstable quality, and achieve simple structure, stable operation, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

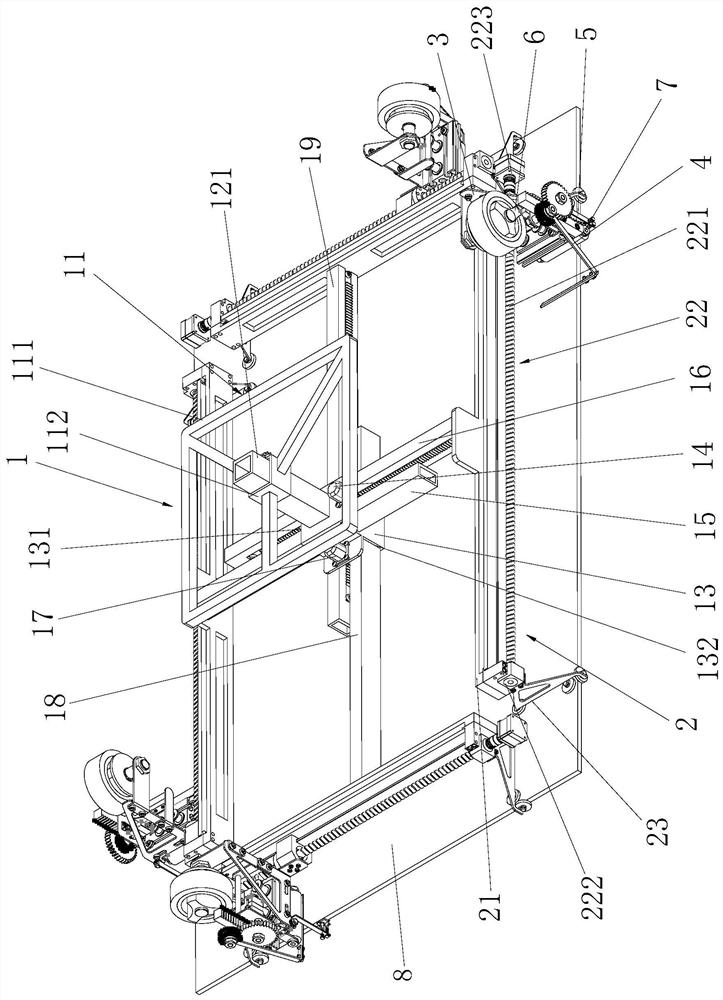

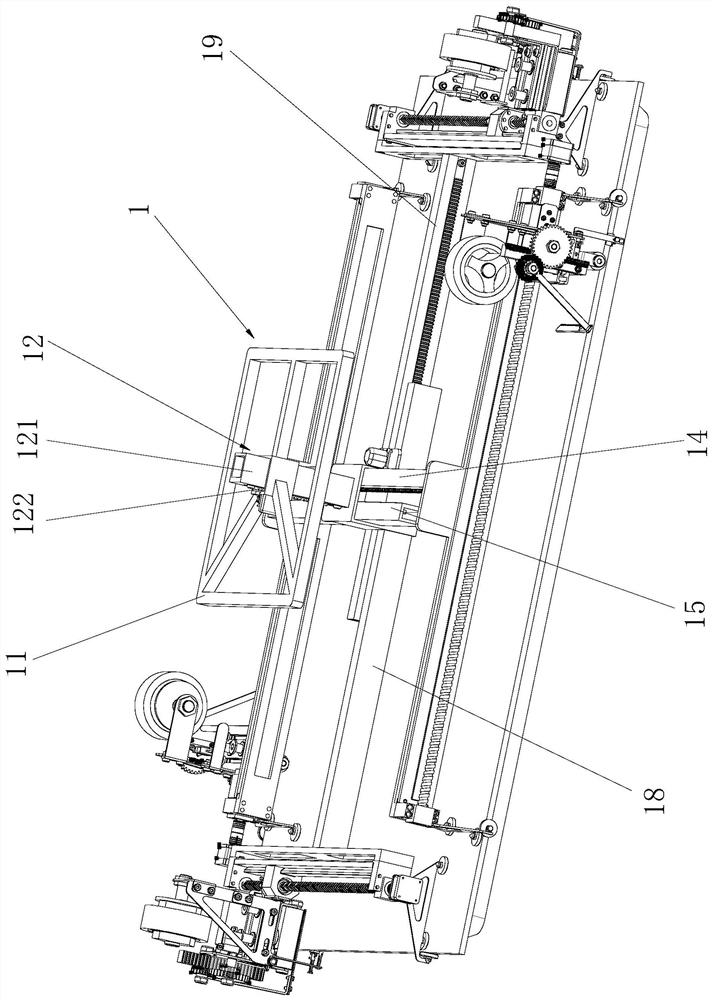

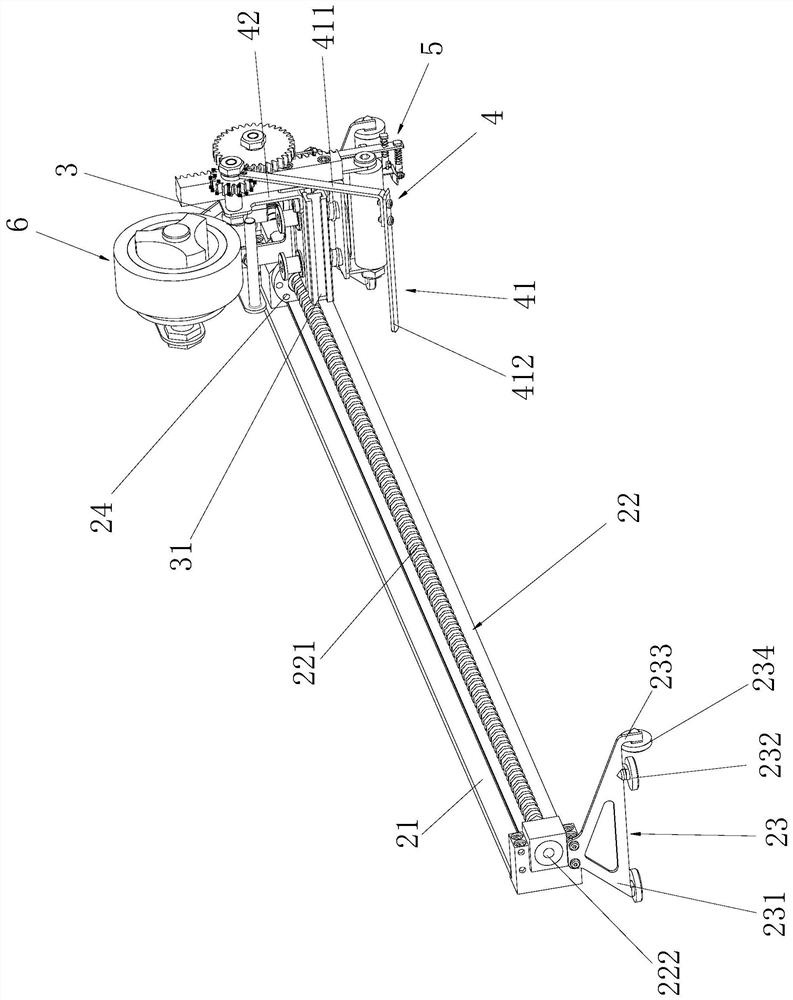

[0049] combine Figure 1 to Figure 6 , a protective film application equipment, including a support mobile device 1 and a film applicator 2 connected to the support mobile device 1 . The film applicator 2 comprises a film sticking support 21, a lead screw module 22 and a film sticking device, the two ends of the film sticking support 21 are connected with a first buffer positioning bracket 23, and the leading screw module 22 is connected to the outside of the film sticking support 21.

[0050] The film sticking device comprises a film sticking main support frame 3, a protective film cutting mechanism 4 and a protective film bending mechanism 5, the film sticking main support frame 3 is connected with the lead screw moving seat 24 connected to the lead screw module 22, and the top of the film sticking main support frame 3 The protective film support mechanism 6 is connected, and the lower end of the film sticking main support frame 3 is connected with a lifting roller mechanism...

Embodiment 2

[0083] When the above-mentioned protective film application equipment is in use, the tape protective film can be applied to the TV screen or other display screens passing under the protective film application equipment. TV screens or monitor screens are sent through assembly lines.

[0084] When the protective film application equipment is performing film application, a film application device is connected to the supporting mobile device 1 . The supporting mobile device is provided with a lifting mechanism, and the lower end of the lifting mechanism drives the film applicator to move through the vertically moving branch pipe and the laterally moving branch pipe. The up and down movement distance of the lifting mechanism in the support mobile device, the longitudinal movement distance of the vertical movement branch pipe, and the lateral movement distance of the lateral movement branch pipe are all controlled by the master controller, and the master controller controls the work...

Embodiment 3

[0088] When the above-mentioned film sticking device sticks a film to the screen 8, the position of sticking the film is the edge of the screen 8. When the film applicator among the present invention is in use, the film tube that needs to be pasted is covered on the protective film holder 63, and the staff stretches the protective film on the film tube. After the stretched protective film is guided by the protective film guide shaft 65, it is initially attached to the screen, and then the lifting roller mechanism 7 descends. The rubber roller 71 in the lifting roller mechanism 7 presses the protective film, and then the film sticking device walks a small distance forward. Then the protective film bending mechanism 5 bends the protective film protruding from the edge.

[0089] The protective film bending mechanism 5 includes a second motor 51 connected to the film main support frame 3, the rotating shaft of the second motor 51 is connected with a first bending strut 52, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com