Drum leather used for original sound drum and electronic drum

A technology of electronic drums and acoustic drums, which is applied to electroacoustic musical instruments, percussion instruments, instruments, etc., can solve the problems of no shock absorption function, high triggering device, inability to adjust elasticity, etc., to improve pronunciation accuracy, reduce production costs, The effect of simplifying supporting facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

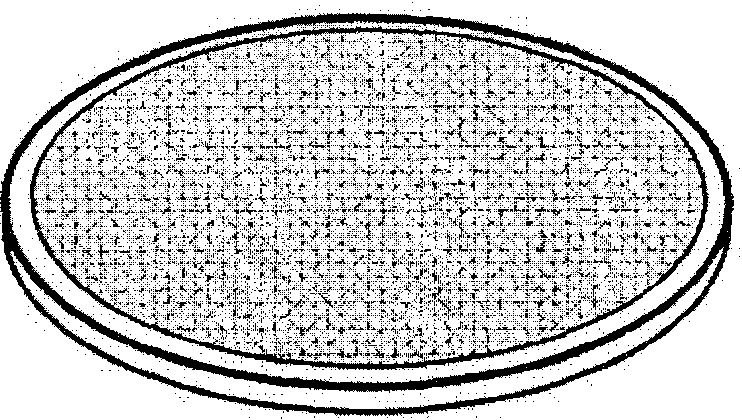

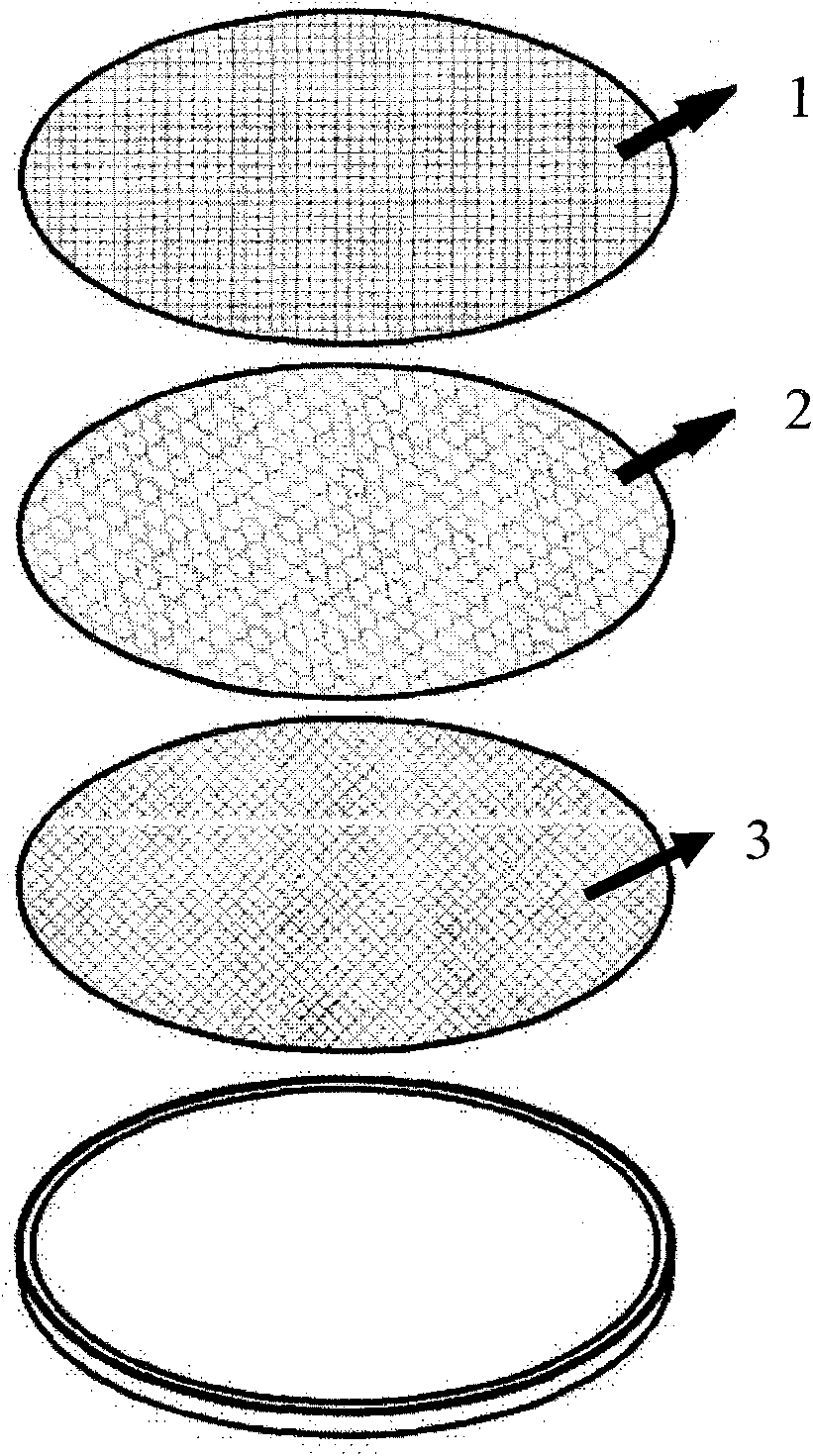

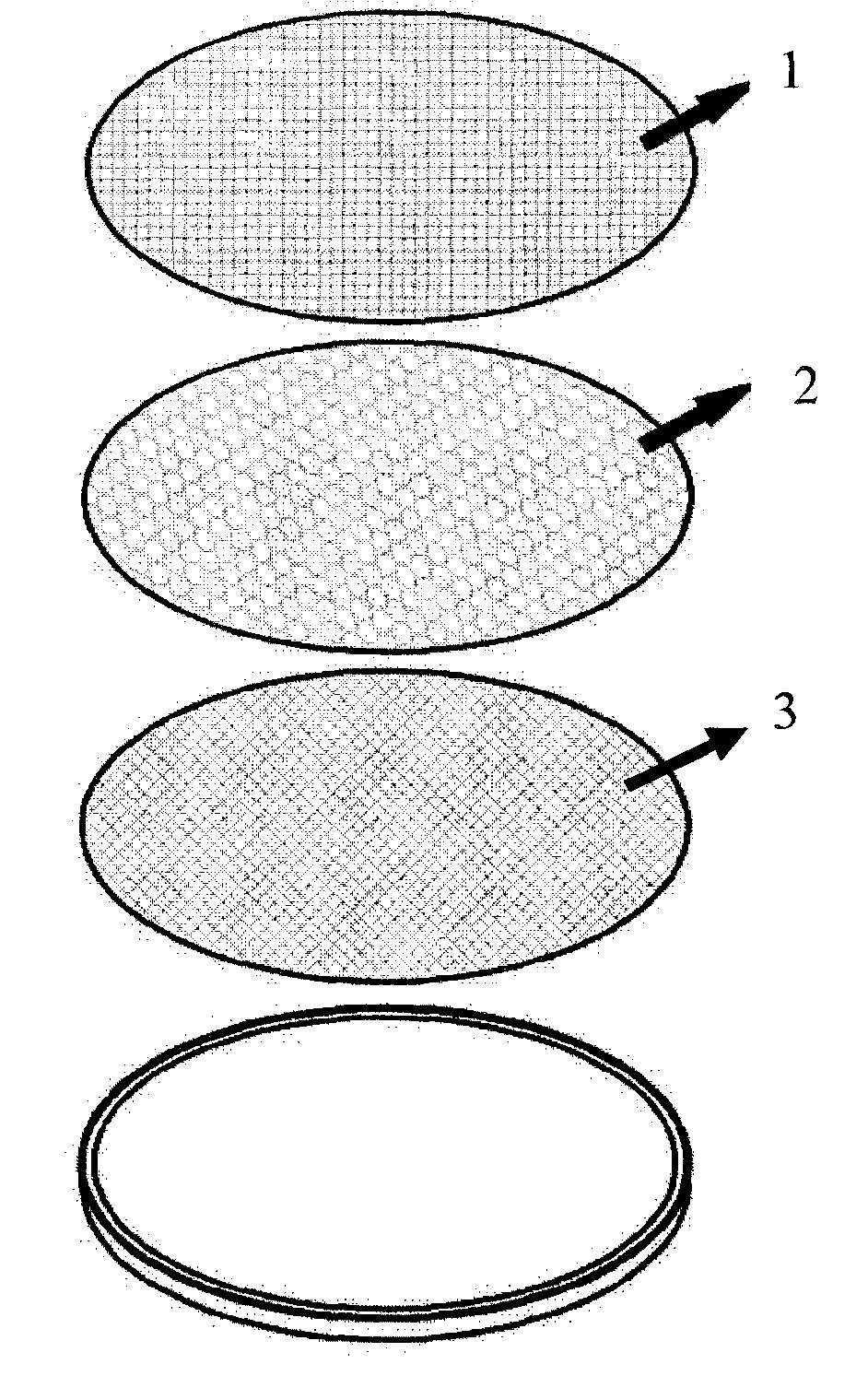

[0012] The drumheads for acoustic drums and electronic drums provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 , figure 2 As shown, the drumheads for acoustic drums and electronic drums provided by the present invention are formed by stacking the surface layer 1, the middle layer 2 and the bottom layer 3, wherein the surface layer 1 as the striking surface is made of polyester mesh, nylon One of silk screen and polyester screen; the middle layer 2 with sound-absorbing and shock-absorbing functions uses polyester spray-coated mesh; and the bottom layer 3 as the supporting layer uses polyester screen, nylon screen and polyester wire one of the nets.

[0014] The mesh number of the surface layer 1 is 40-80 mesh, and the thickness is 0.10-0.35 mm.

[0015] The thickness of the middle layer 2 is 0.2-0.3 mm.

[0016] The bottom layer 3 has a mesh number of 40-80 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com