Electronic switch operation anti-jumping circuit

A switch operation and anti-jumping technology, which is applied in the direction of panel/switch station circuit devices, etc., can solve the problems of poor versatility, different coil internal resistance, and large difference in starting current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

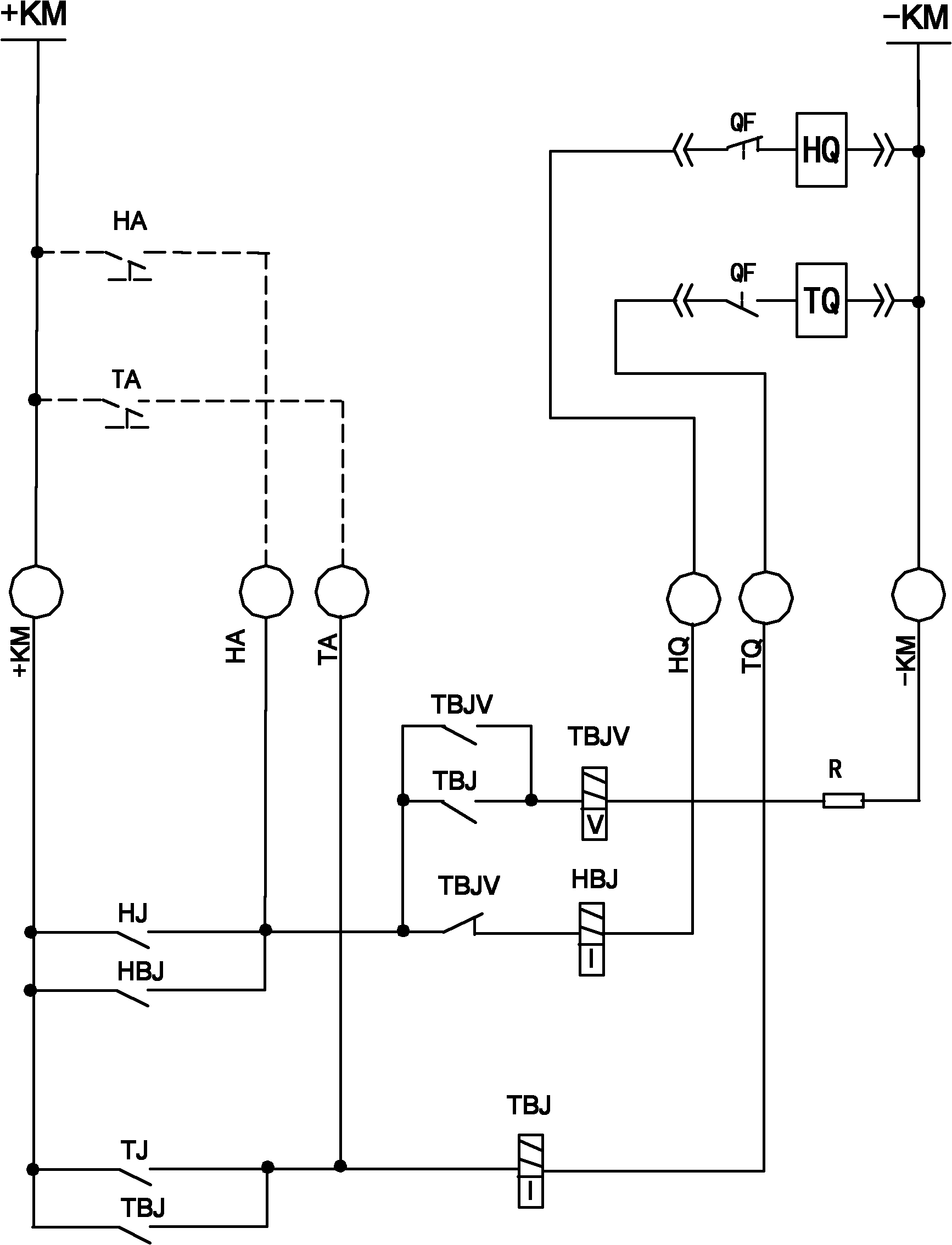

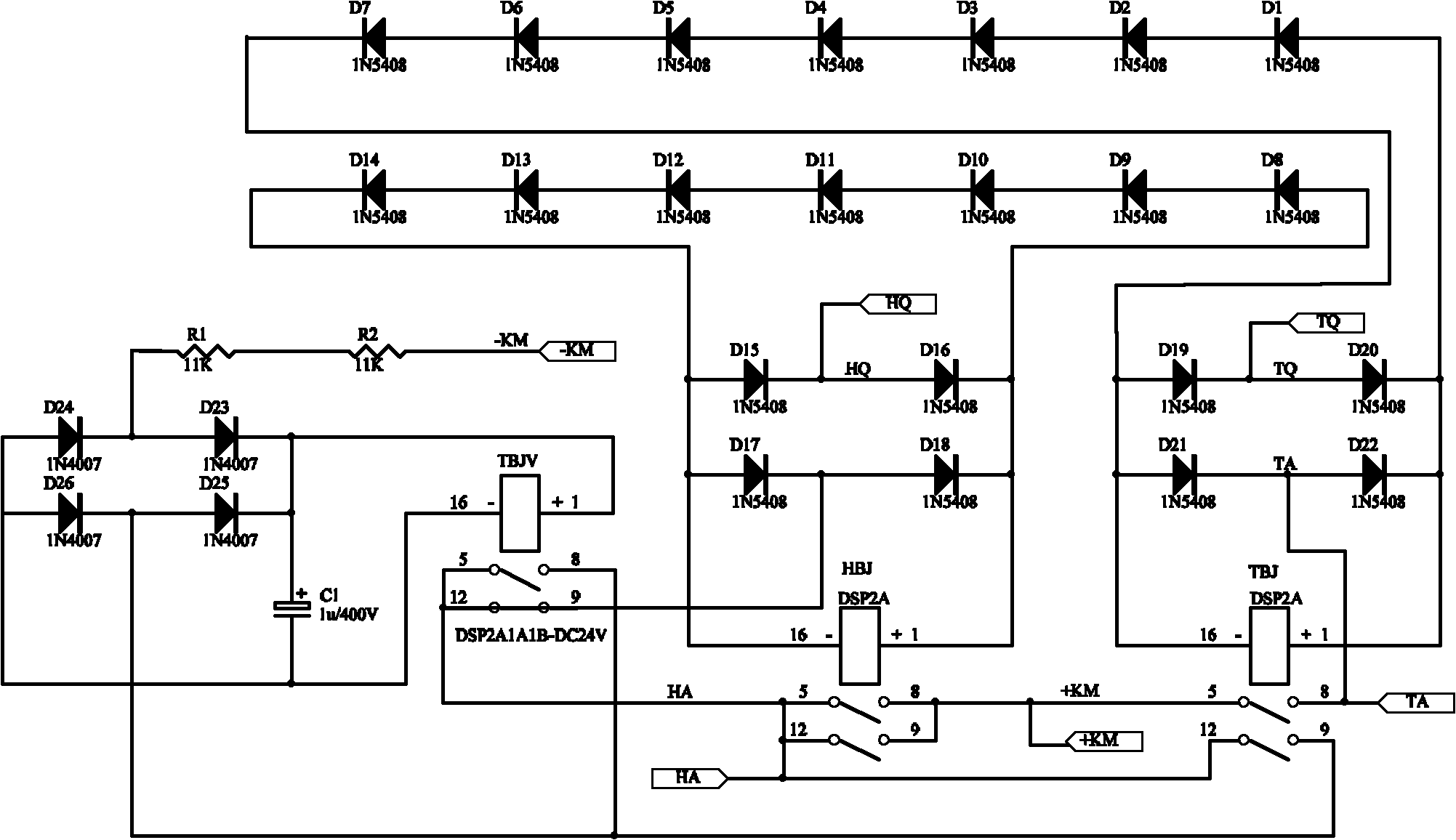

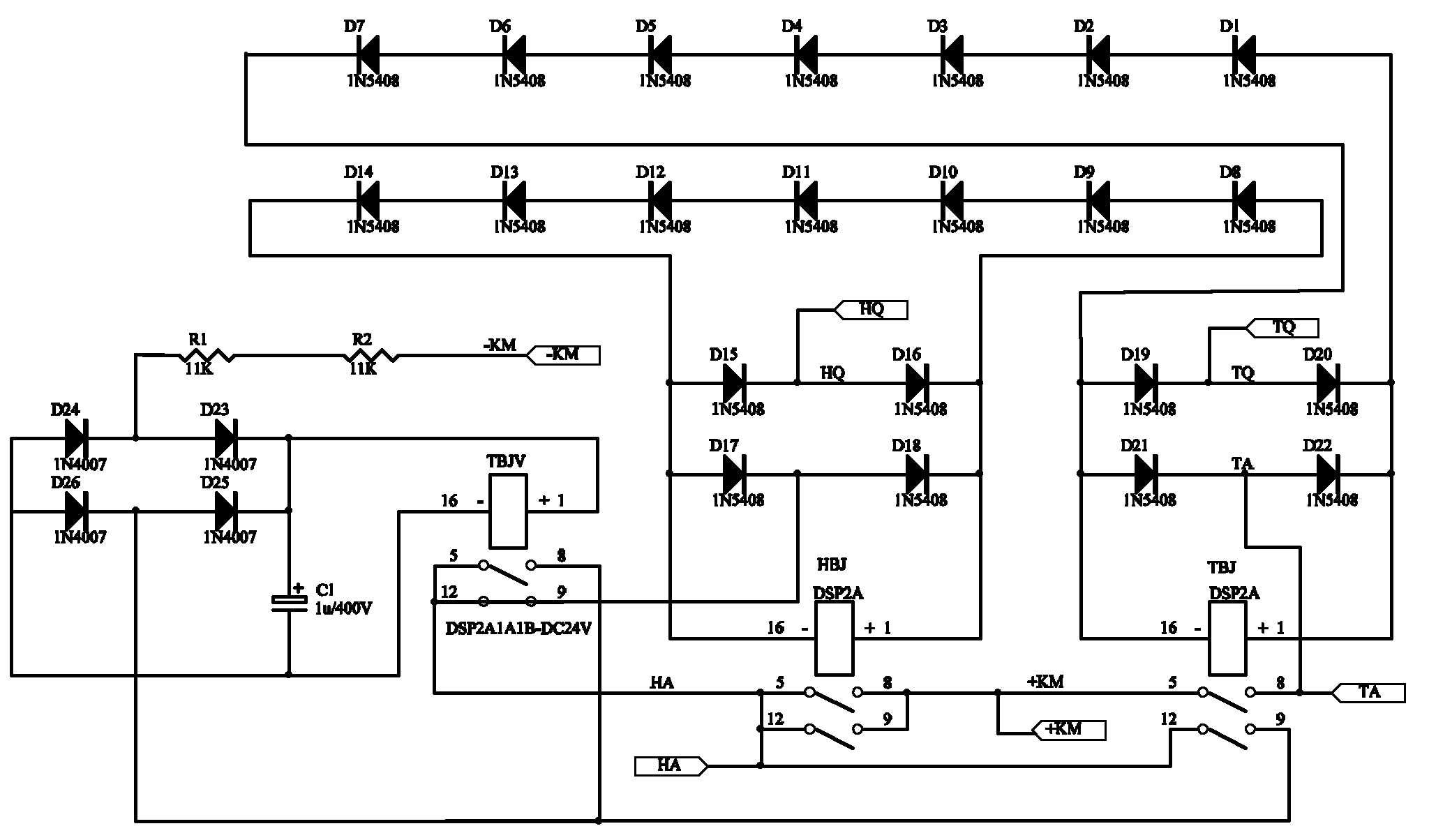

[0015] refer to figure 1 , In the switch operation anti-jump circuit, +KM and -KM are the positive and negative poles of the control power supply respectively, the HA and HQ nodes are the access points of the closing intermediate relay HBJ, and the TA and TQ nodes are the access points of the opening intermediate relay TBJ . The opening control circuit is sequentially connected in series between the positive and negative poles +KM and -KM of the control power supply, and consists of the opening button TA, the TA node, the coil of the opening intermediate relay TBJ, the TQ node, and the opening coil TQ. The closing control loop is composed of the closing button HA, the HA node, a group of normally closed contacts of the auxiliary intermediate relay TBJV, the coil of the closing intermediate relay HBJ, and the closing coil HQ. A group of normally open contacts of the opening intermediate relay TBJ, the coil of the auxiliary intermediate relay TBJV and matching resistor R are co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap