Multipoint needle valve

A needle valve, multi-point technology, applied in the field of needle valve, can solve the problems of difficult matching of valve needle and gate, easy leakage of valve needle sleeve, complicated needle valve installation and disassembly, etc., to achieve beautiful glue port marks and control waste. , the effect of enhancing behavioral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] According to the claims of the present invention and the content disclosed in the summary of the invention, the technical solution of the present invention is specifically as follows:

[0029] The needle valve in the prior art has the problems of complicated installation and disassembly, easy material leakage of the valve needle sleeve, and difficult cooperation between the valve needle and the gate.

[0030] The invention discloses a multi-point needle valve to solve the above problems:

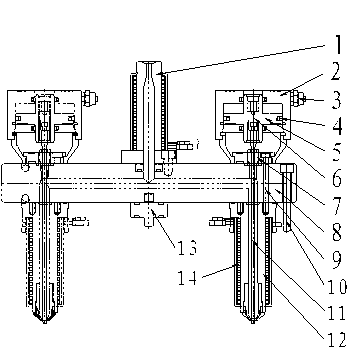

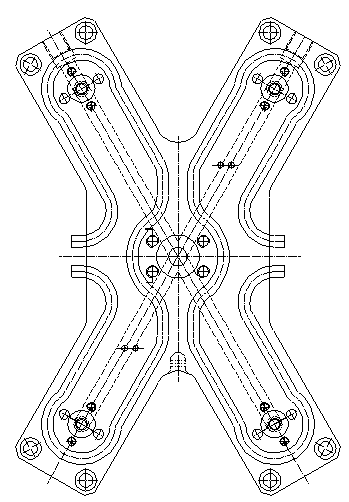

[0031] figure 1 It is a structural schematic diagram of the multi-point needle valve of the present invention, please refer to figure 1 , a multi-point needle valve, including:

[0032] A first needle valve, the specific structure of the first needle valve is:

[0033] A first hot nozzle 12 is set below a splitter plate 8, and a first cylinder block 2 is correspondingly arranged on the splitter plate 8, and a hot nozzle fixing screw 9 passes through the bottom of the first cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com