Vacuum pump with two helical rotors

A vacuum pump and spiral technology, applied in the field of pumping devices, can solve problems such as unusable, achieve fast rotation, good compression rate, and avoid backflow pollution

Inactive Publication Date: 2010-08-18

ALCATEL LUCENT SAS

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this type of pump cannot be used where heating of the gas within the pumping unit is required and / or higher pressures

Factories are always looking to reduce the size and cost of equipment in their manufacturing rooms, especially in the semiconductor industry where clean room space is at a premium

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

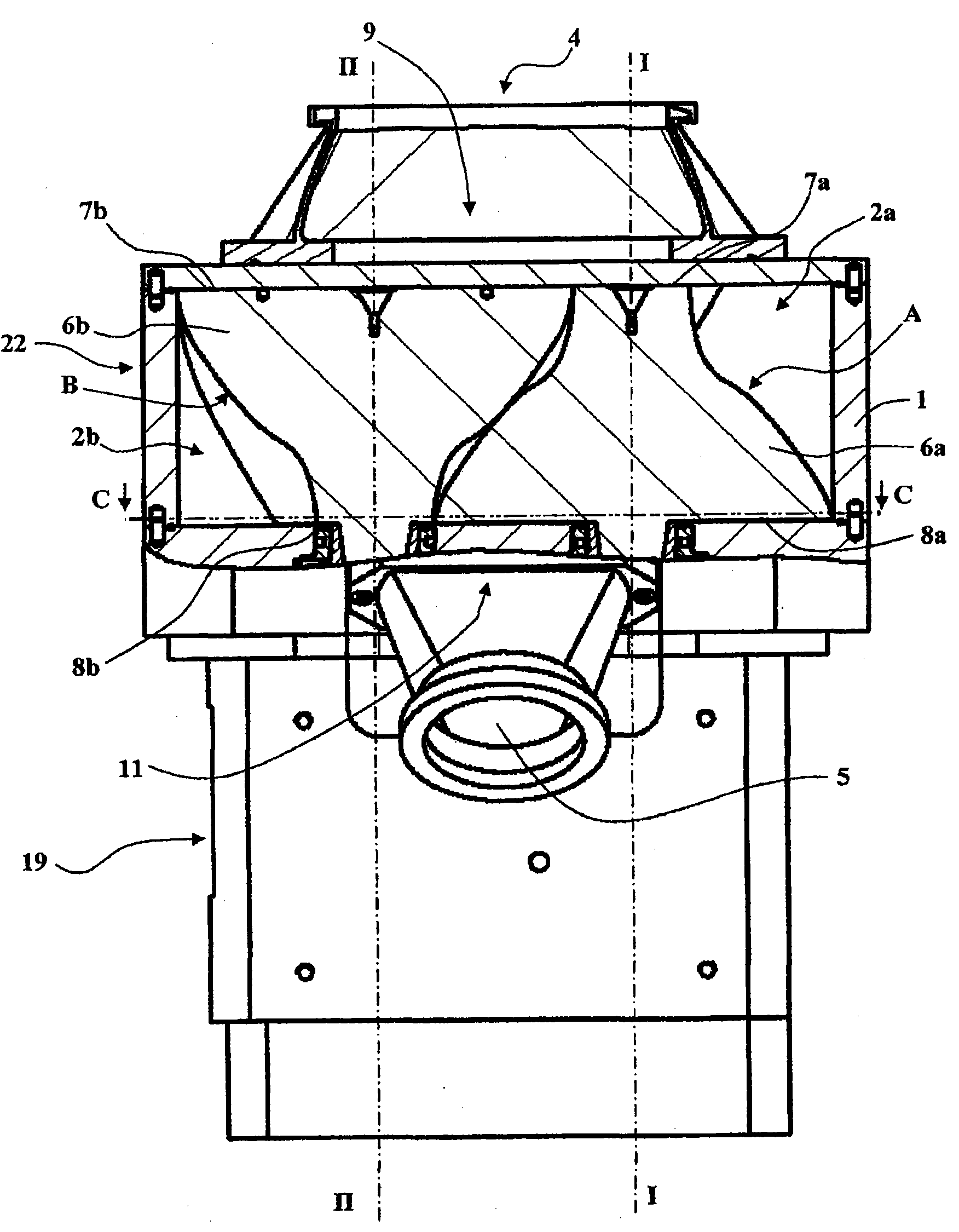

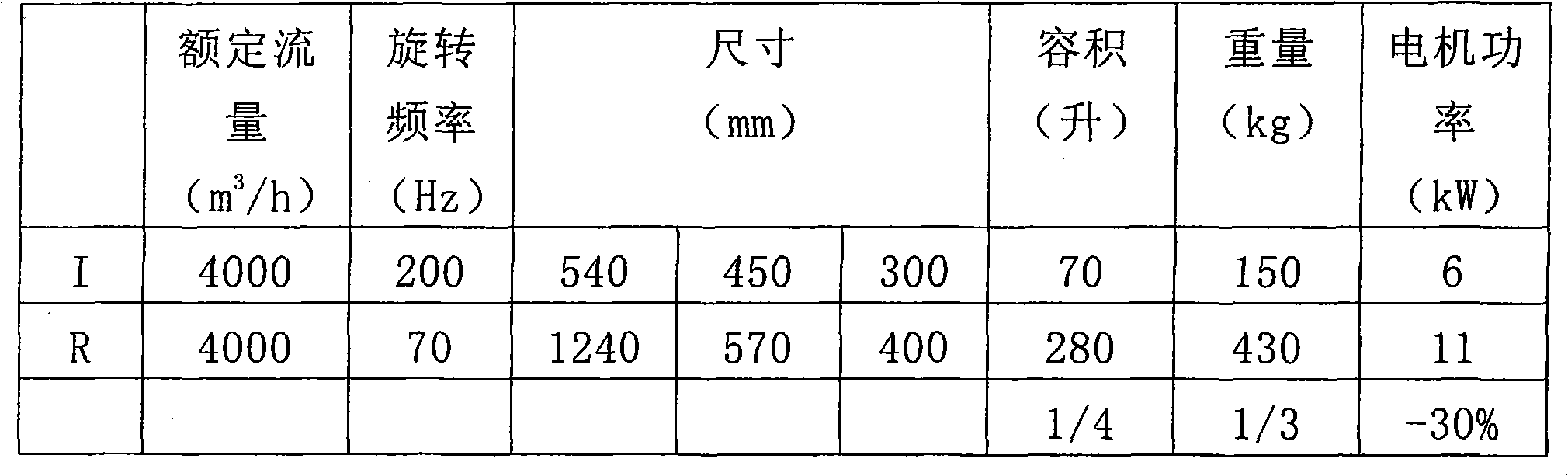

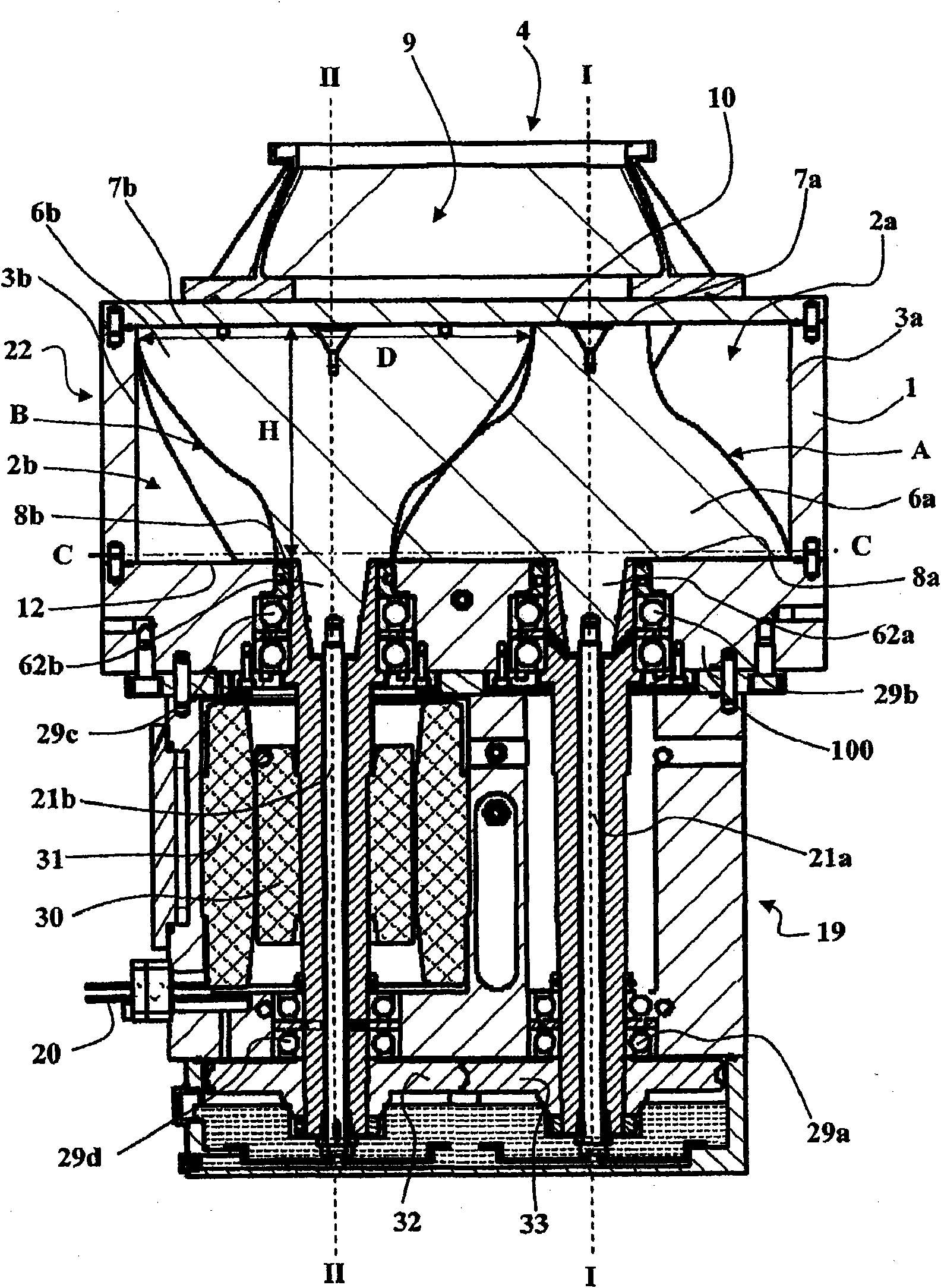

The invention relates to a vacuum pump comprising a housing (1), a mechanical portion (19) and a pumping portion (22). The pumping portion (22) includes two meshed helical rotors (A, B) each having a helical torsion about a longitudinal axis. The rotors (A, B) are short and held in an offset position in the downstream direction. An inlet passage (4) communicates with the inside of the housing (1) via an inlet opening (9). An outlet passage (5) communicates with the inside of the housing (1) via an outlet opening (11). The inlet and the outlet are axial relative to the axes of the helical rotors (I-I, II-II).

Description

technical field The present invention relates to pumping means capable of creating and maintaining a suitable vacuum within an apparatus. Background technique Generating and maintaining a vacuum within equipment is common in industrial semiconductor manufacturing because some manufacturing steps must be performed in a vacuum. During these manufacturing steps, the device is connected to a pumping device that reduces the internal pressure of the device until a suitable vacuum is achieved. In practice, known pumping devices generally include at least one main pump and at least one auxiliary pump, at least one main pump is placed at the discharge port of the vacuum line, and at least one auxiliary pump is connected in series between the main pump and the pump of the equipment in the flow path of the pumped gas. The first known pumping device is used to reduce the pressure in the equipment from about 10 -2 The situation in the pressure interval from mbar to about 10 mbar. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04C18/12F04C23/00F04C25/02

CPCF04C2240/402F04C25/02F04C18/126

Inventor 伯努特·巴赫德

Owner ALCATEL LUCENT SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com