Card edge connector

A technology of card edge connectors and connecting grooves, which is applied in the direction of connection, parts of connection devices, fixed/insulated contact members, etc., which can solve the problems of terminal damage, large volume, and too much space, and achieve height reduction and volume reduction , to avoid the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

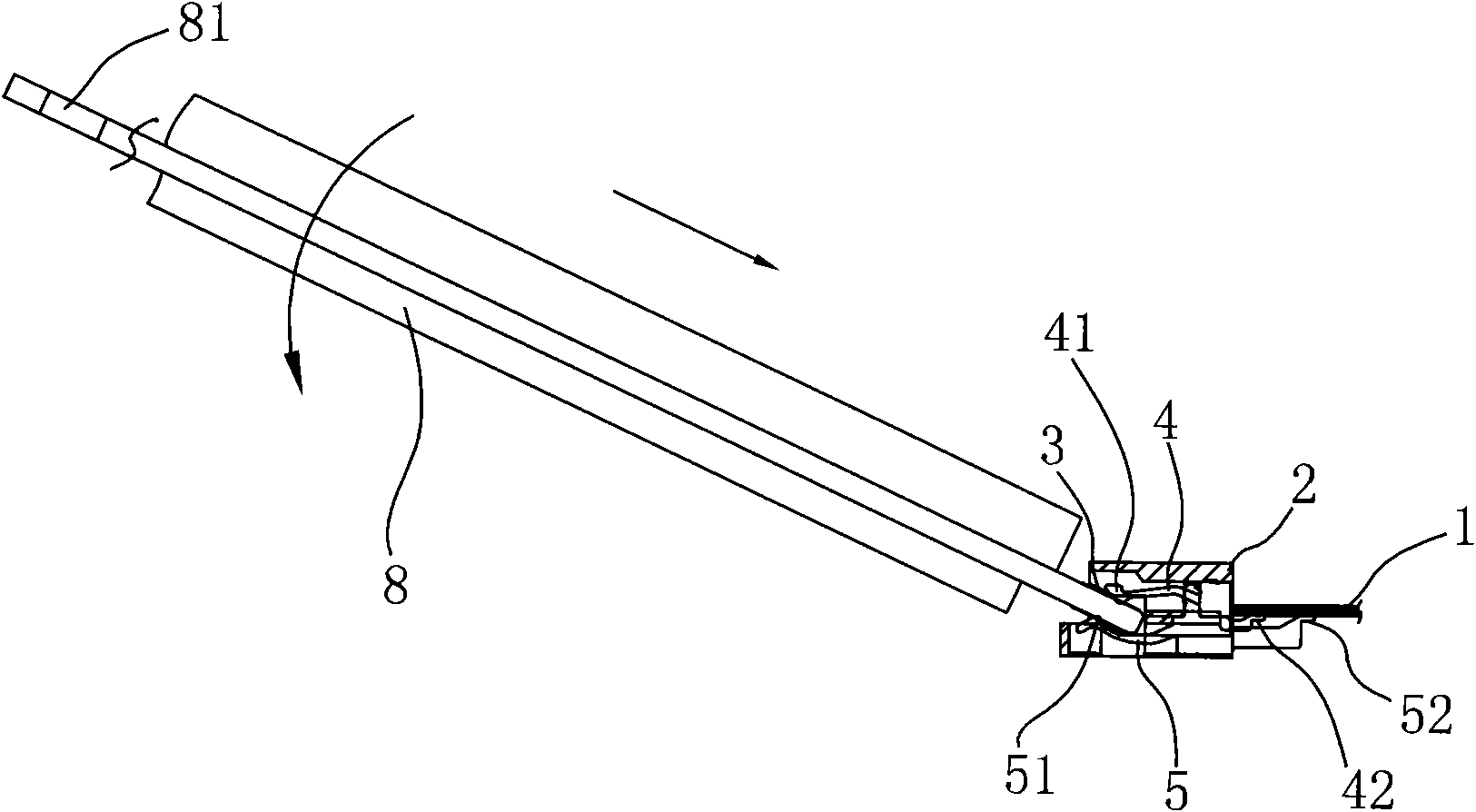

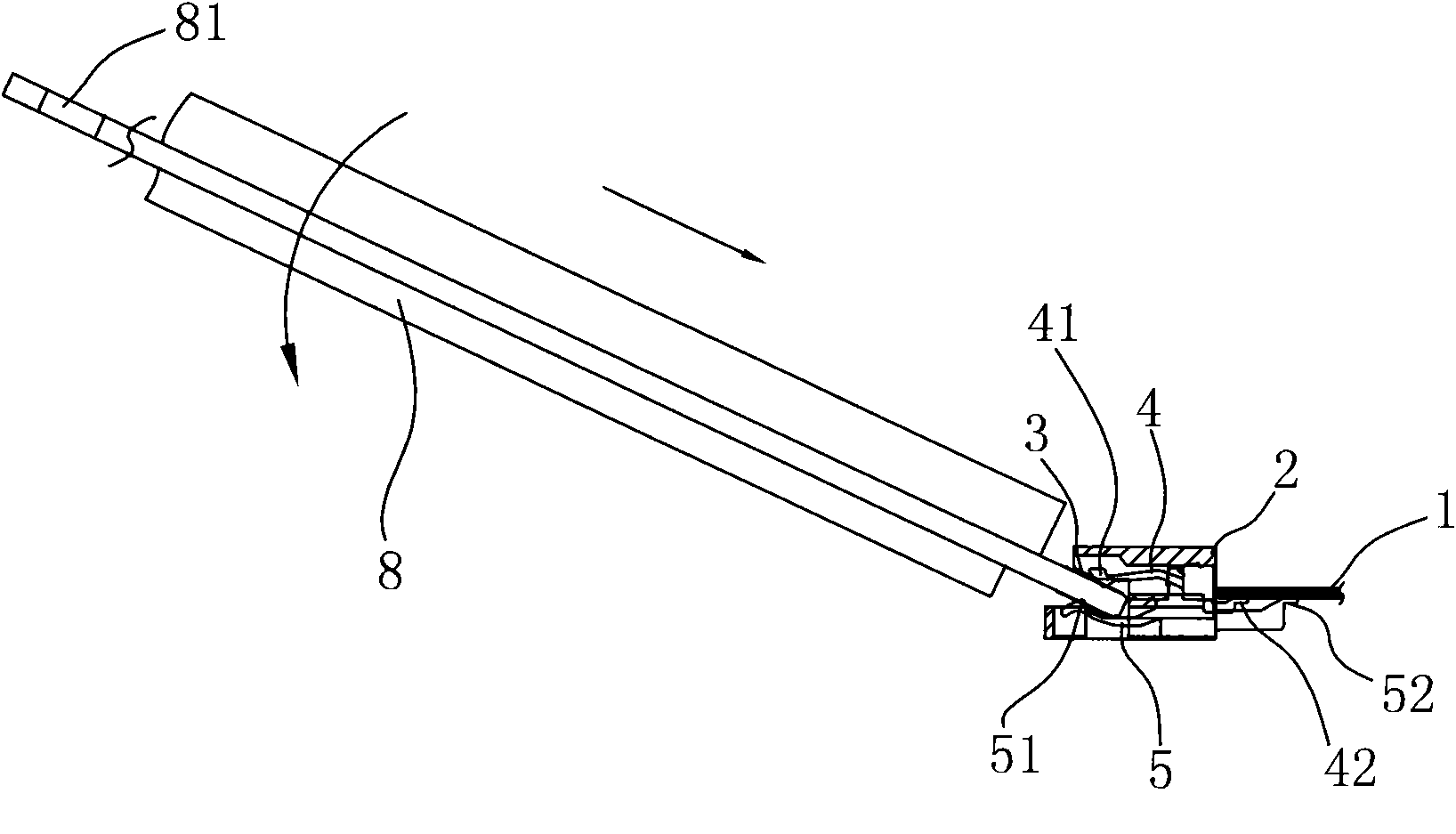

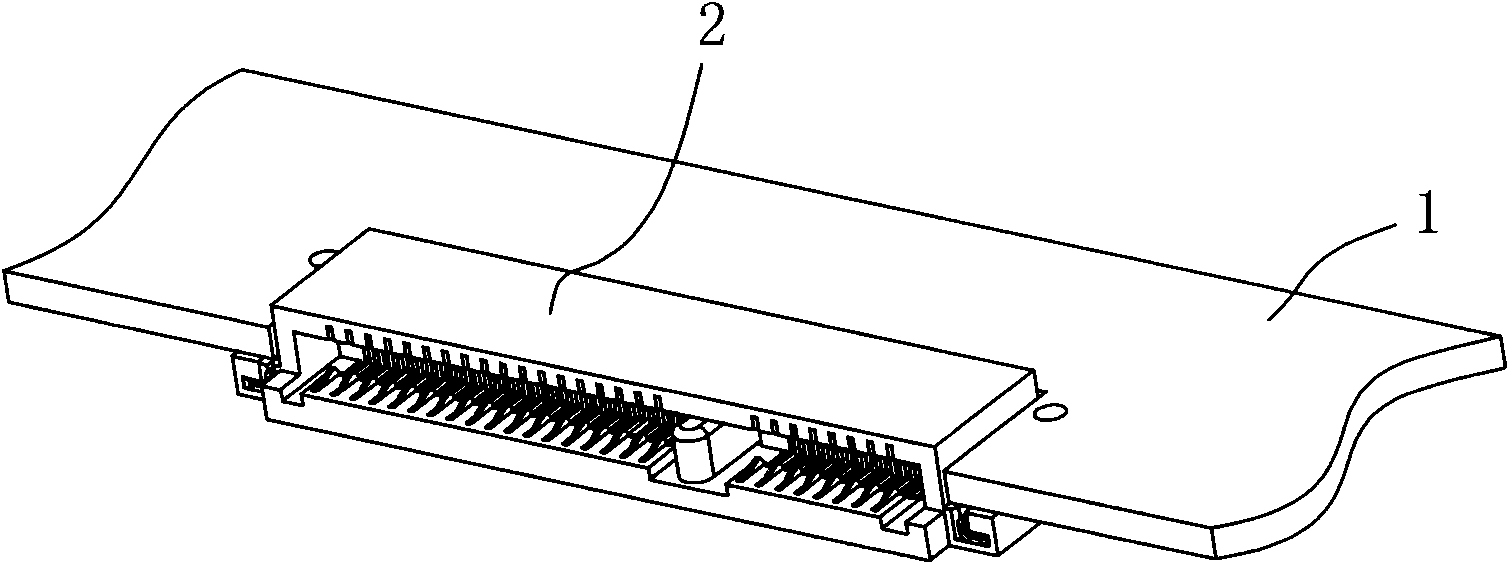

[0022] Embodiment: A card edge connector, including an insulating body 2 welded to the mother circuit board 1, the insulating body is provided with a connecting groove 3 for inserting one end of the daughter circuit board, and plural numbers are respectively accommodated in the insulating body. The first and second rows of conductive terminal slots 6, 7 of the first and second rows of conductive terminals 4, 5, the contact parts 41, 51 of the first and second rows of conductive terminals are located in the connecting groove and can elastically resist one end of the sub-circuit board 8 respectively The first and second rows of conductive terminal welding parts 42, 52 pass through the insulating body and are welded to the mother circuit board, and the other end of the sub-circuit board corresponding to one end of the sub-circuit board is locked and attached to the external mechanism 10 in parallel. , taking the entrance of the connection groove as the front, the connection groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com