A kind of preparation method and product of negative Poisson's ratio bio-based rigid foam material

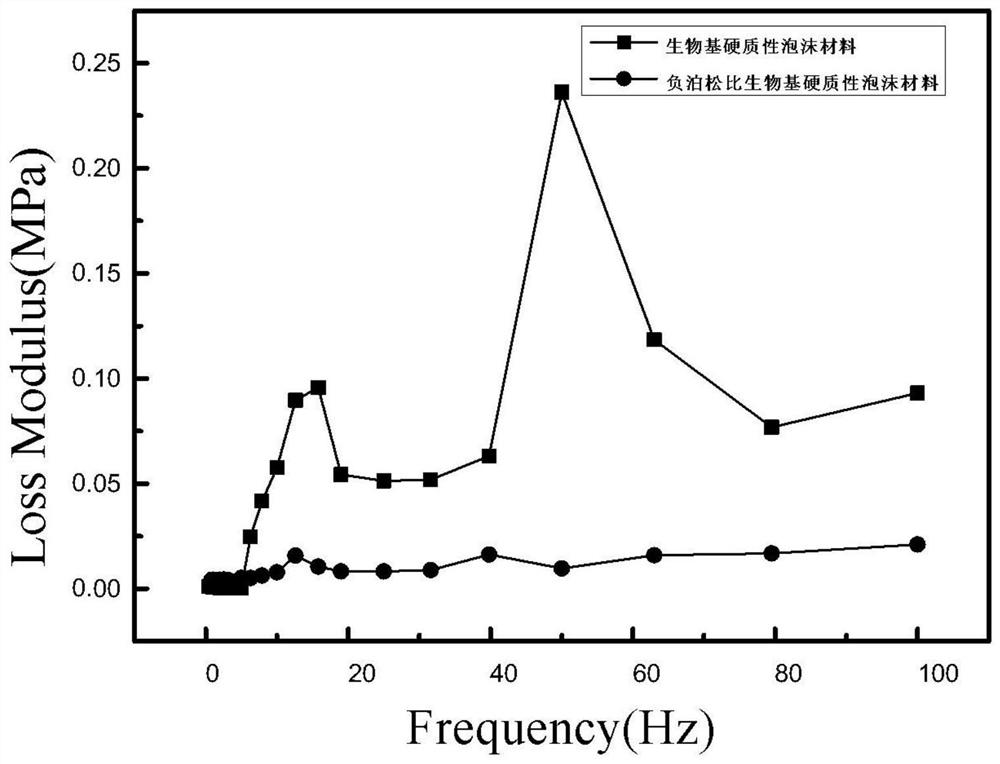

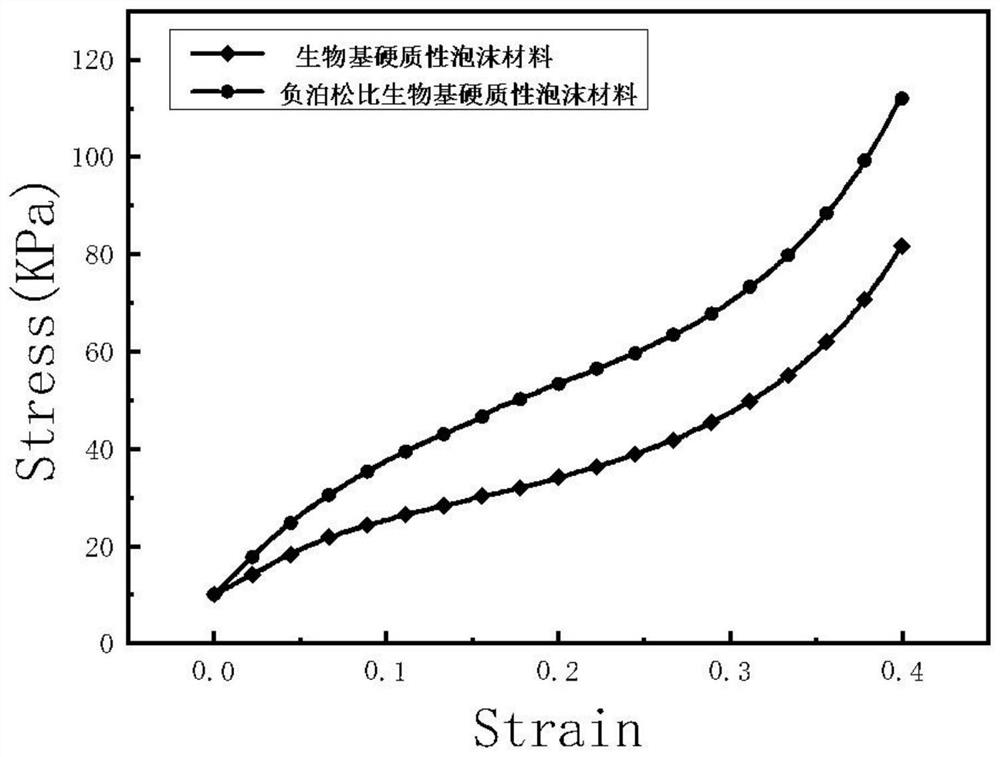

A foam material and negative Poisson's ratio technology, which is applied in the field of preparation of negative Poisson's ratio bio-based rigid foam materials, can solve the problems of complicated process and unfavorable industrialization, and achieve low equipment requirements, low cost, and excellent compression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

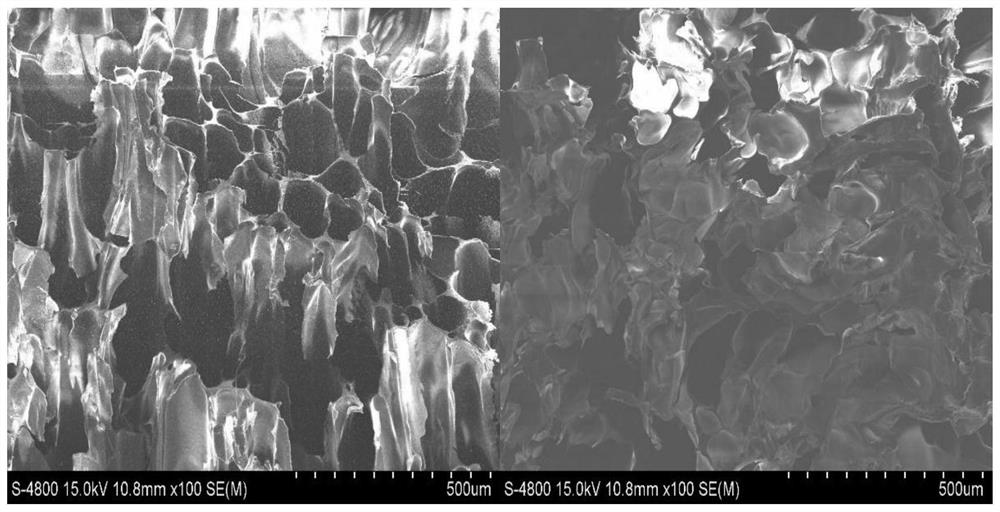

[0027] Preparation of Negative Poisson's Ratio Bio-based Rigid Foams

[0028] (1) polybutylene succinate is placed in the autoclave whose inner cavity is cylindrical, the autoclave is closed and carbon dioxide is passed into the autoclave and the air in the autoclave is exhausted, and carbon dioxide is continued to be passed into the autoclave to high pressure After the pressure in the autoclave was 8MPa, carbon dioxide was stopped, heated to 120°C for 2h, then cooled to 96°C for 10min, and the pressure in the autoclave was reduced to atmospheric pressure within 3s, and the product was taken out and cooled to room temperature, Preparation of bio-based rigid foam material;

[0029] (2) heating the bio-based rigid foam material obtained in step (1) to 102° C., and compressing the bio-based rigid foam material in the axial and circumferential directions after holding for 0.5 h, wherein the axial The compression ratio was 30%, and the compression ratio in the circumferential dire...

Embodiment 2

[0031] Preparation of Negative Poisson's Ratio Bio-based Rigid Foams

[0032] (1) polylactic acid is placed in the autoclave that the inner cavity is cylindrical, the autoclave is closed and carbon dioxide is passed into the autoclave and the air in the autoclave is exhausted, and the pressure in the autoclave that continues to feed carbon dioxide is 9MPa Then stop feeding carbon dioxide, heat up to 170°C for 3h, then cool down to 155°C for 12min, then reduce the pressure in the autoclave to the atmospheric pressure level within 3s, take out the product and cool it to room temperature to obtain bio-based rigid Sexual foam material;

[0033] (2) heating the bio-based rigid foam material obtained in step (1) to 55° C., and compressing the bio-based rigid foam material in the axial and circumferential directions after holding for 0.5 h, wherein the axial The compression ratio was 10%, and the compression ratio in the circumferential direction was 30% to obtain a bio-based rigid ...

Embodiment 3

[0035] Preparation of Negative Poisson's Ratio Bio-based Rigid Foams

[0036](1) polyhydroxy fatty acid ester is placed in a cylindrical high-pressure reactor with inner cavity, closed this high-pressure reactor and feed carbon dioxide to the high-pressure reactor and the air is exhausted, continue to feed carbon dioxide to the high-pressure reactor After the pressure was 8.5MPa, the introduction of carbon dioxide was stopped, heated to 180°C and kept for 2.5h, then cooled to 168°C for 15min, and then the pressure in the autoclave was reduced to the atmospheric pressure level within 3s, and the product was taken out and cooled to room temperature. Bio-based rigid foam material;

[0037] (2) heating the bio-based rigid foam material obtained in step (1) to 110° C., and compressing the bio-based rigid foam material in the axial and circumferential directions after holding for 1 h, wherein the axial compression The compression ratio in the circumferential direction is 20%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com