Ultrasonic cleaning device of motor winding

A technology for ultrasonic cleaning and motor windings, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as difficult cleaning of motor windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

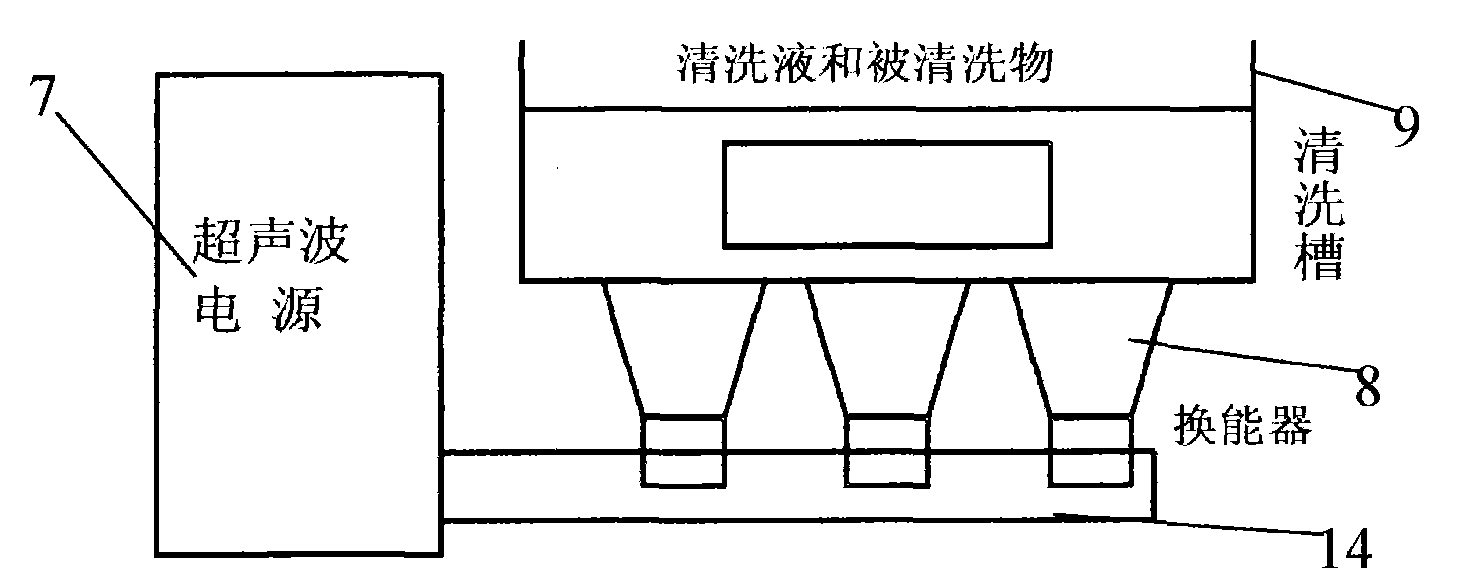

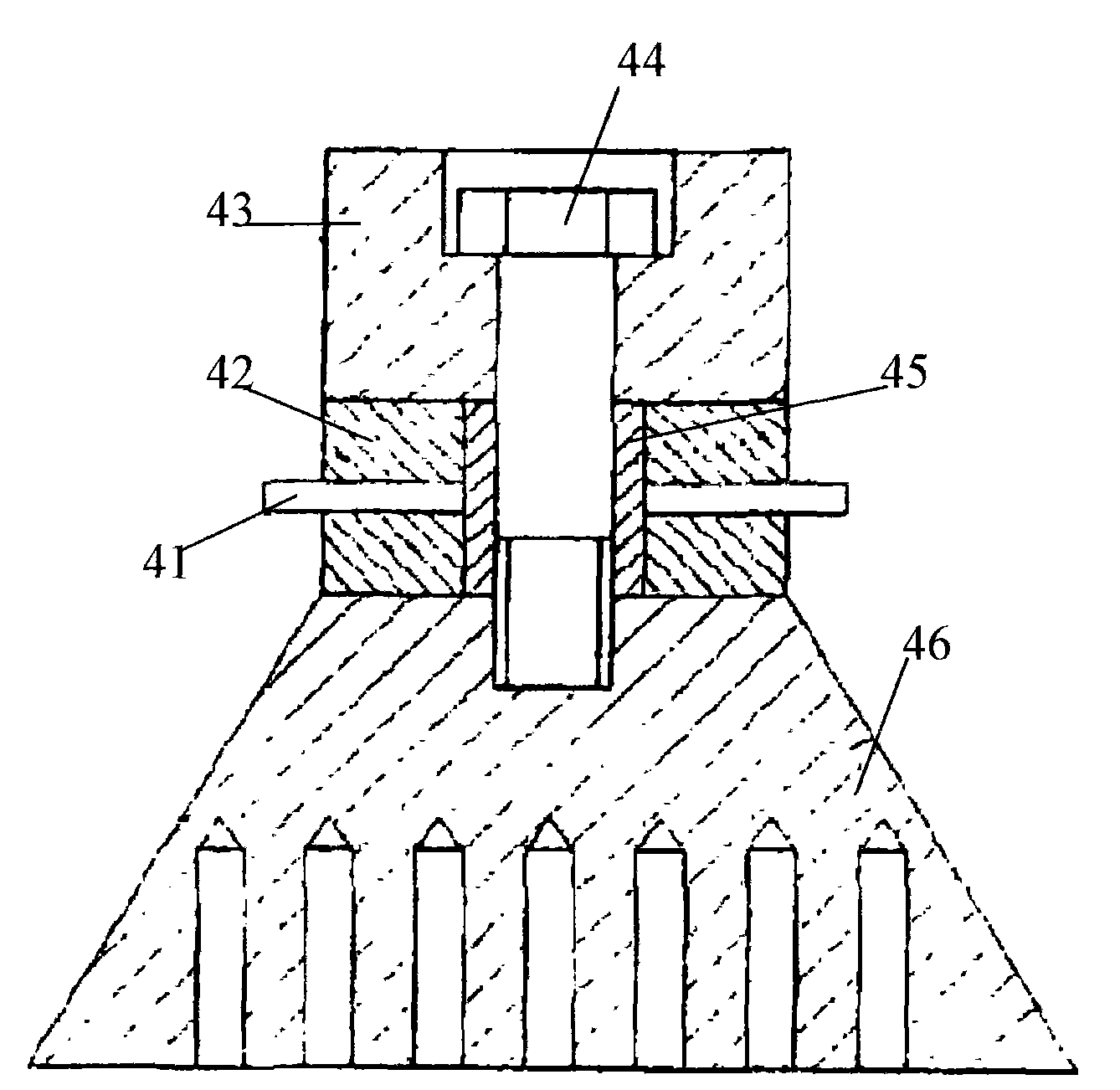

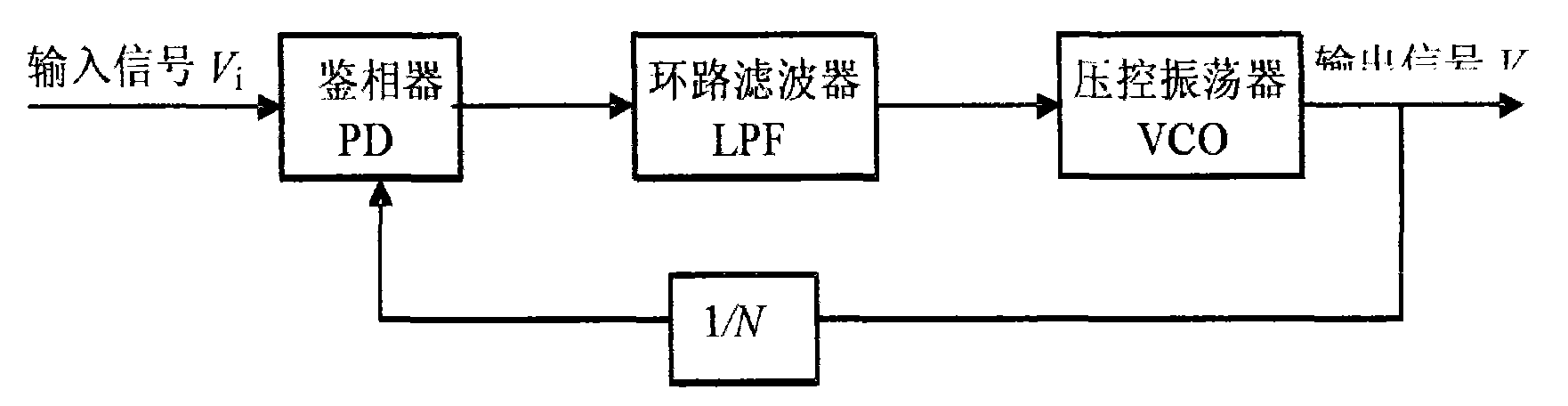

[0035] Such as figure 1 As shown, the motor winding ultrasonic cleaning device of the present invention consists of a control cabinet 1, a body 2, a control area 3, a control circuit 4, a protection circuit 5, a drive circuit 6, an ultrasonic generator 7, an ultrasonic transducer 8, and a cleaning tank 9. Cleaning liquid filtration circulation device 10, A heat preservation cover 11, B heat preservation cover 12, pneumatic pull rod 13, cable 14 and drain valve 15; the front of the control cabinet 1 is provided with a control area 3, and the control area 3 is connected to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com