Pipeline defect and magnetic leakage detection device

A technology of magnetic flux leakage detection and detection device, which is used in pipeline systems, material magnetic variables, mechanical equipment, etc., can solve the problems of low magnetization, blockage of pipeline variable diameter parts, and inability to magnetize oil pipes, so as to improve the magnetization, improve the Deformation, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0022] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

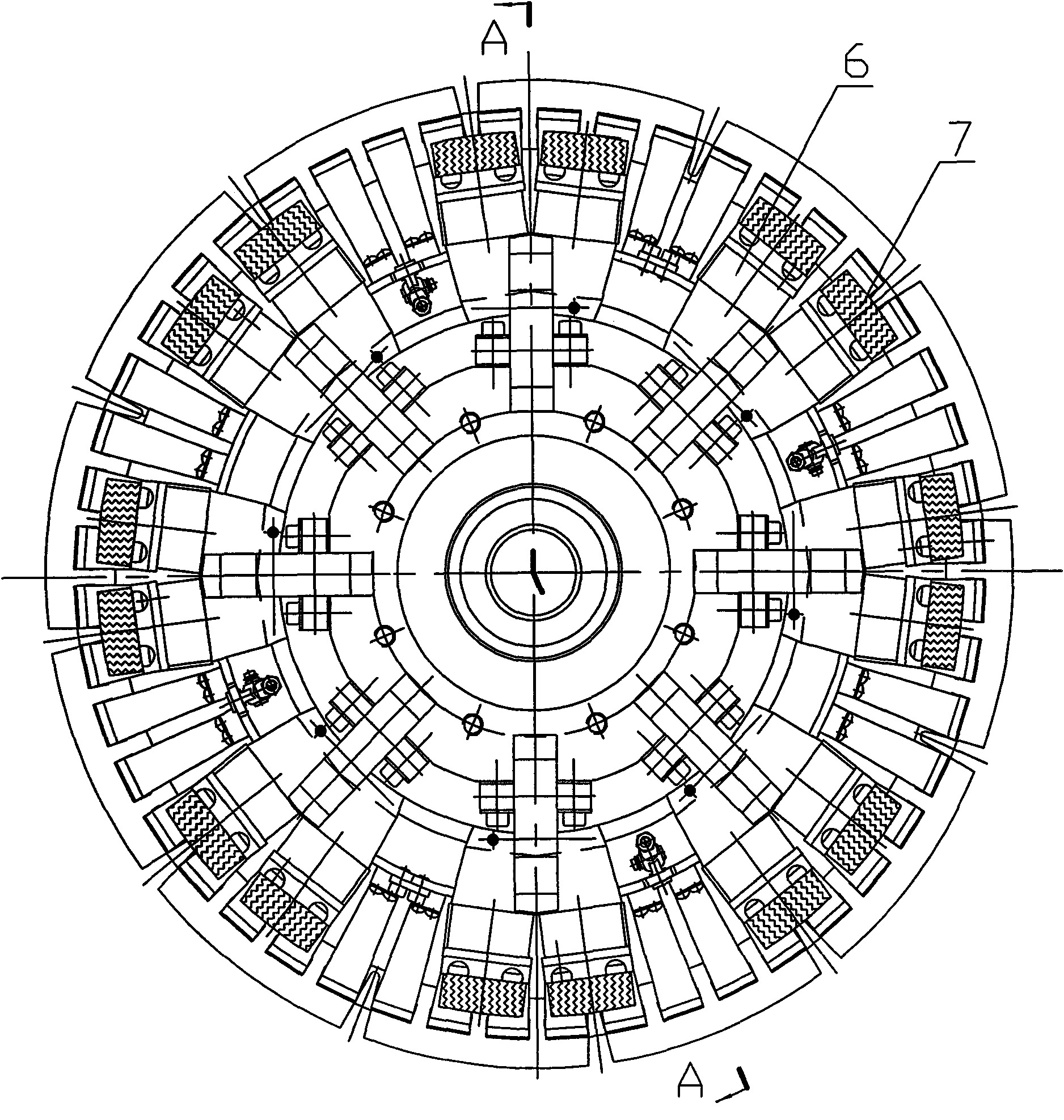

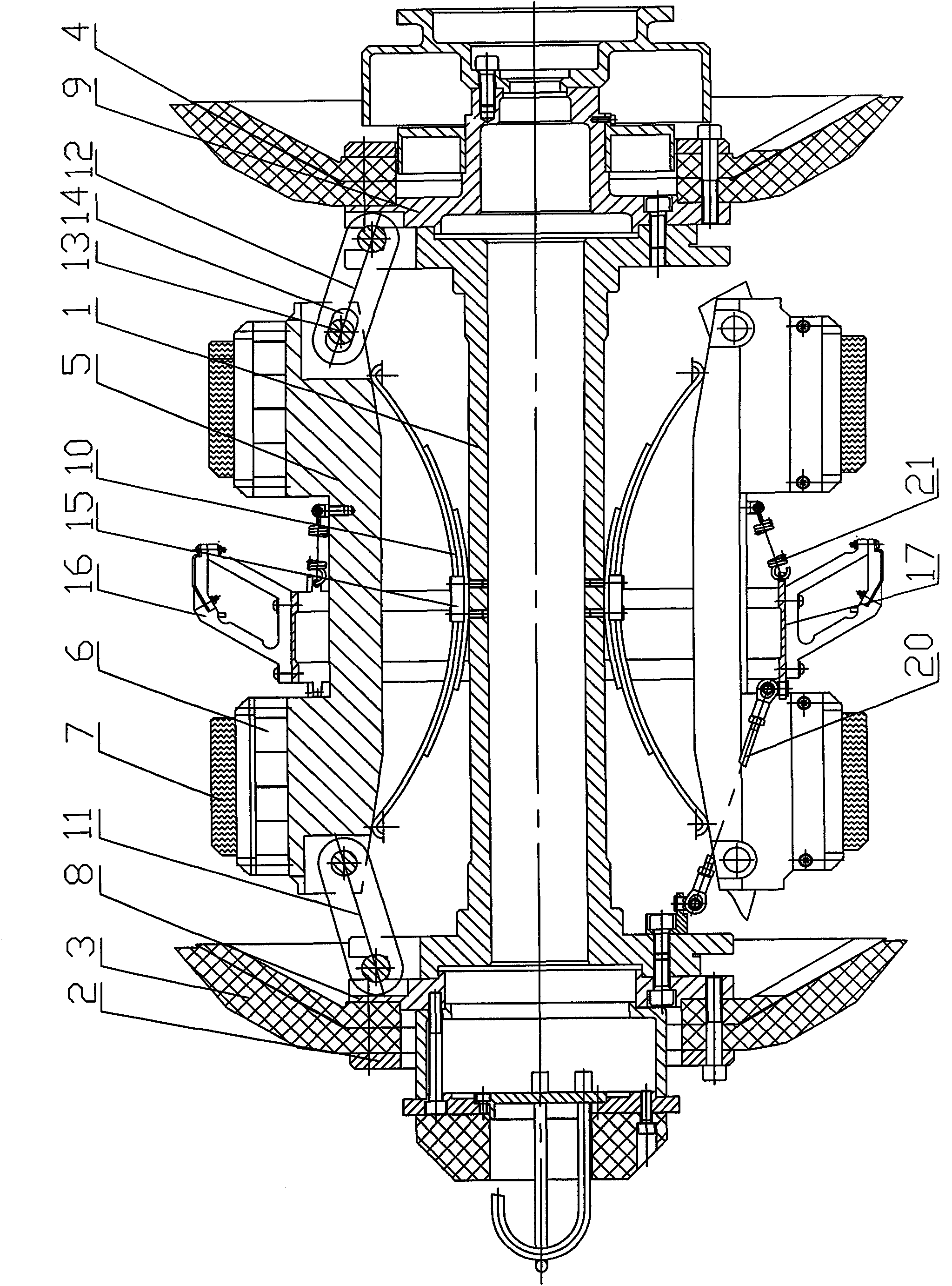

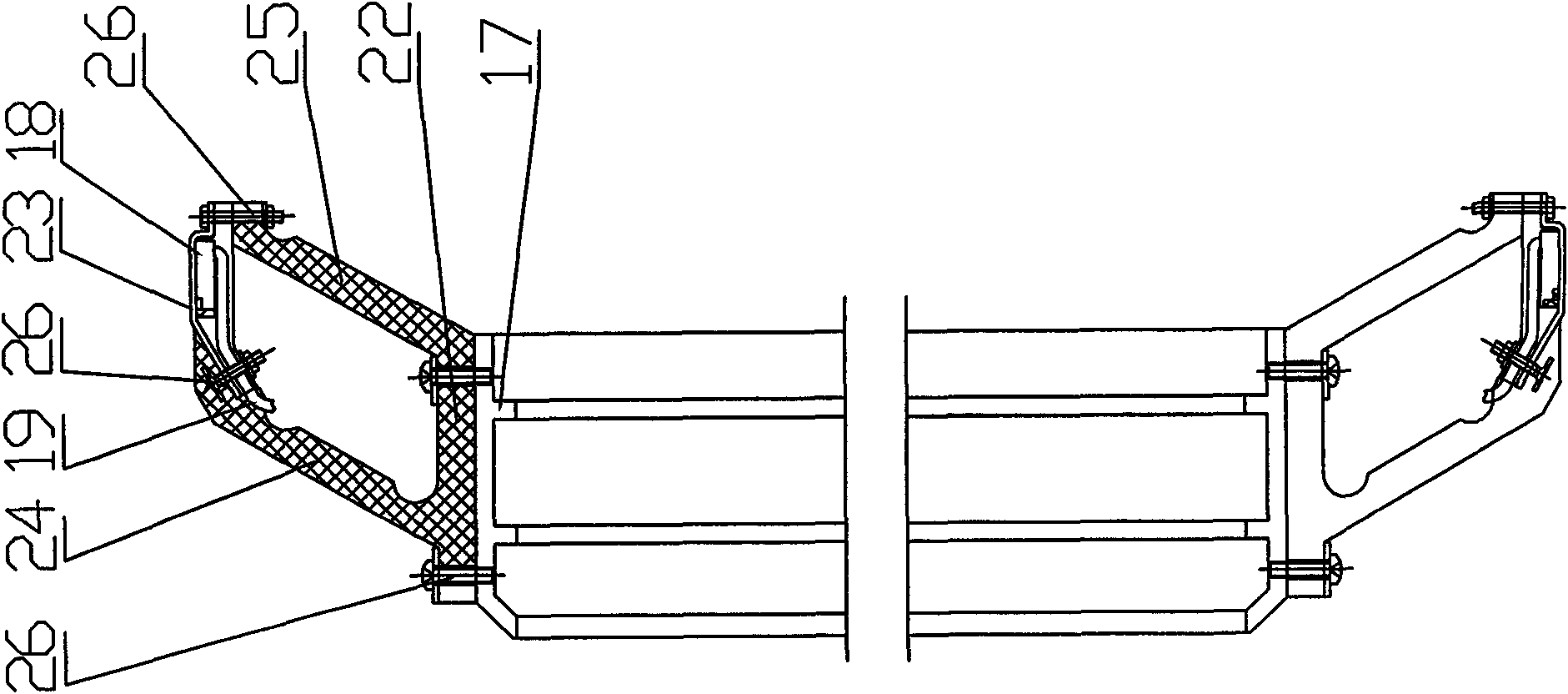

[0023] as attached figure 1 , 2 As shown, the pipeline defect magnetic flux leakage detection device includes a central shaft 1, a magnetic conduction device and a magnetic flux leakage detection device; a left leather cup 3 and a right leather cup are fixedly installed at both ends of the central shaft 1 through a flange plate and a pressure plate 2 4. On the central axis 1 between the left cup 3 and the right cup 4, a magnetic conduction device capable of guiding the detected pipeline is installed, and a magnetic flux leakage device capable of detecting magnetic flux leakage signals is installed outside the middle of the magnetic conduction device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com