Construction method for dividing unit to prefabricate bearing bent frame

A construction method and unit-by-unit technology, which is applied in the field of unit-by-unit prefabricated load-bearing bent frame construction, can solve problems such as high construction safety risks, low work efficiency, and potential safety hazards, and achieve the effects of eliminating safety risks and shortening the straight-line construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

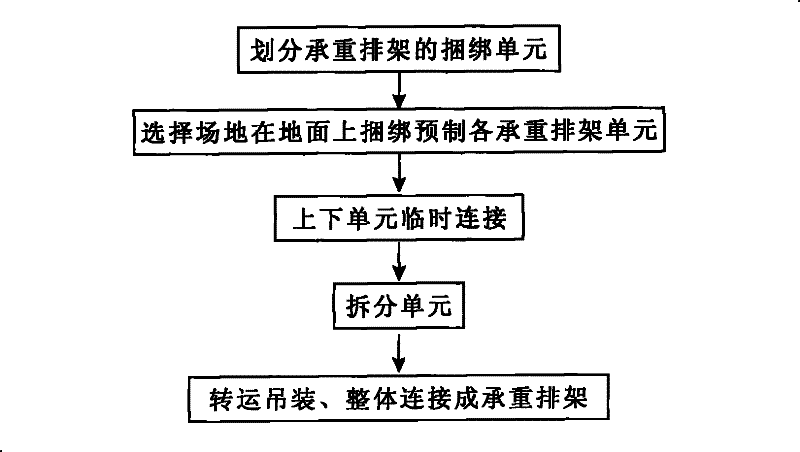

[0023] Example: such as figure 1 Among them, the sub-unit prefabricated load-bearing bent frame construction method includes the following steps:

[0024] 1) Divide each load-bearing bent unit of the load-bearing bent rack;

[0025] 2) Select a site to bind and prefabricate each load-bearing bent unit on the ground;

[0026] 3) The upper and lower units are temporarily connected;

[0027] 4), split unit;

[0028] 5), transfer hoisting, the overall connection into a load-bearing bent frame.

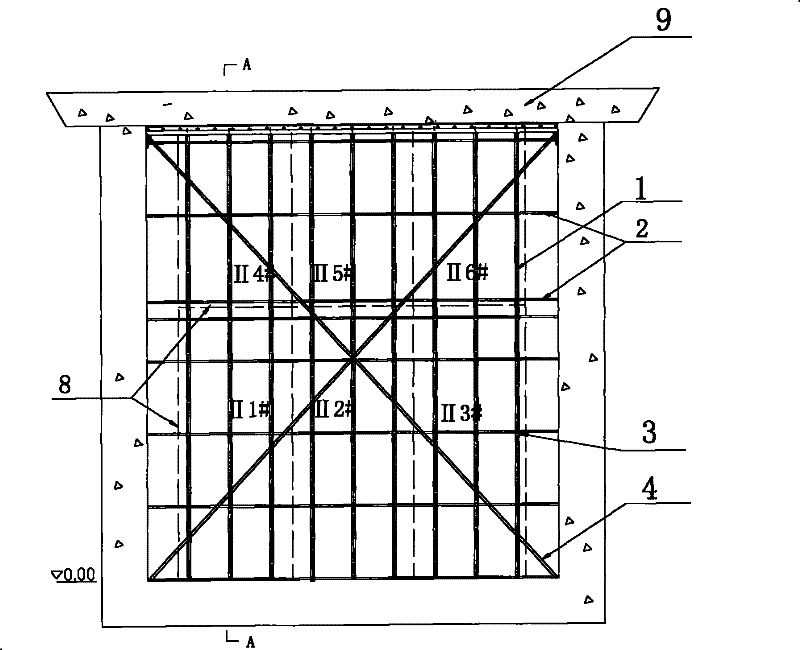

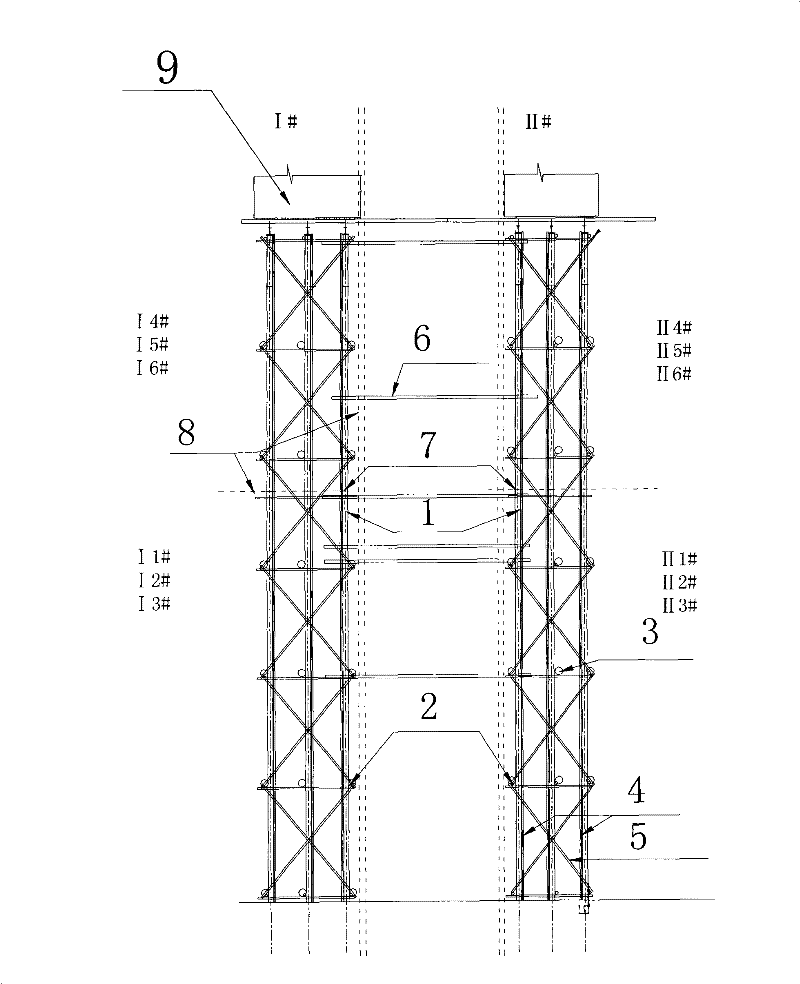

[0029] The load-bearing bent unit is the smallest unit for hoisting. The principle of unit division is: under the premise of meeting the working performance of the equipment lifting the unit, the requirements of the transfer tool and the road for the unit length, width and weight, the total number of units is the least; The unit specifications and shapes should be the same as possible. Such as figure 2 with image 3 In this embodiment, according to the unit splitting line 8, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com