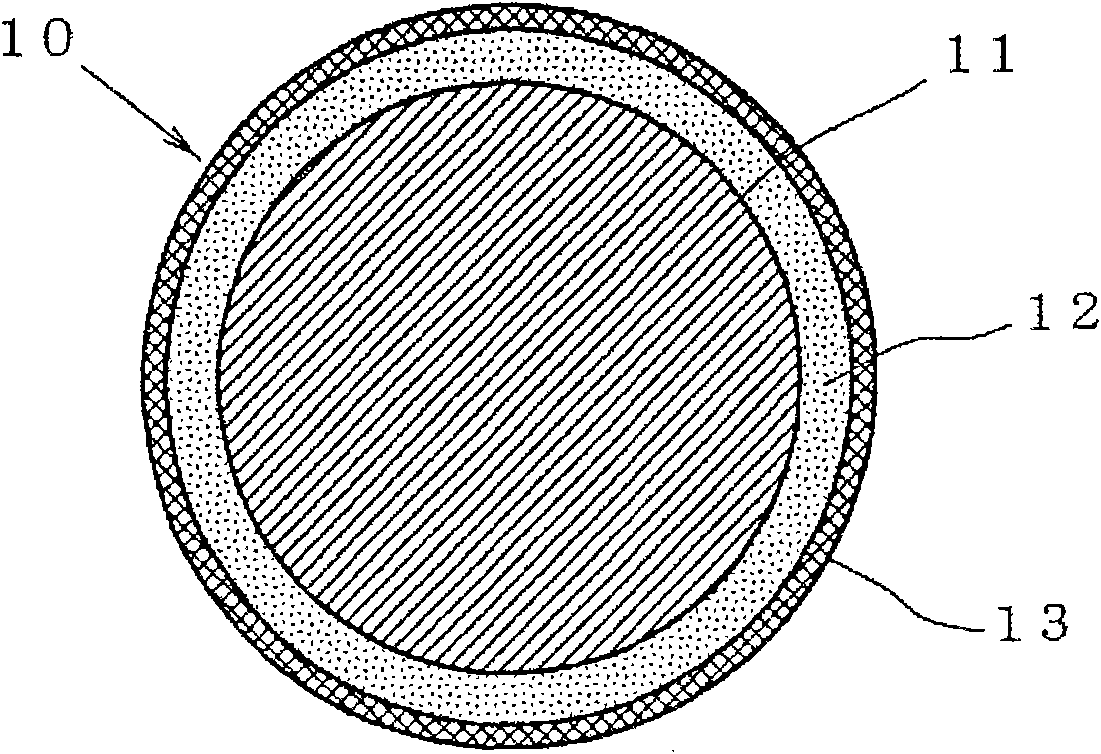

Insulated electric wire

一种绝缘电线、润滑剂的技术,应用在绝缘电缆、绝缘体、绝缘导体等方向,能够解决变瘪形状、不良等问题,达到优异线圈插入性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

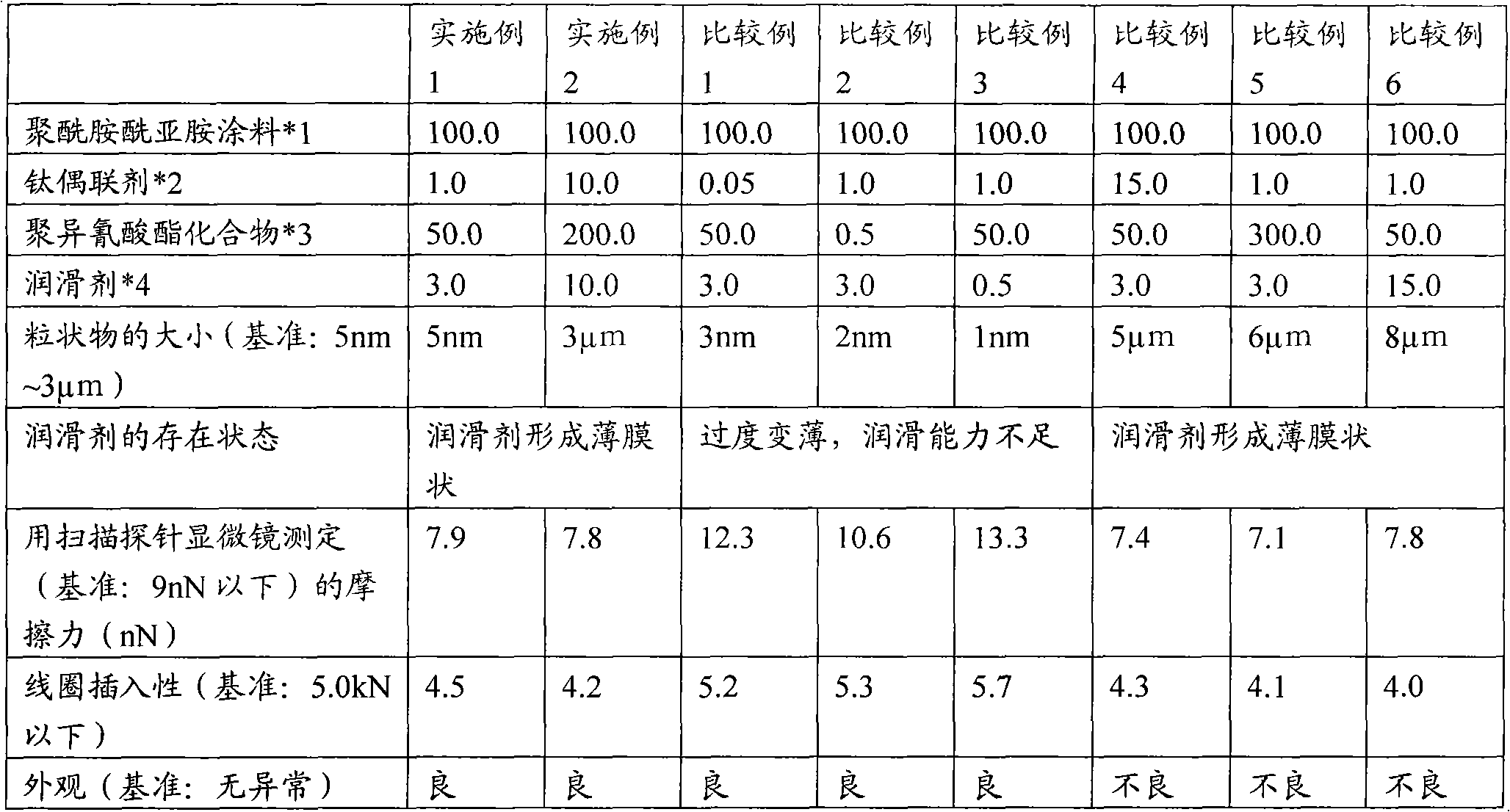

[0069] To 100 parts by mass of polyamideimide paint HI-406-30 (manufactured by Hitachi Chemical Co., Ltd.), Mitsui "HI-WAX 110P" manufactured by Chemical Corporation, "Plenact KR41B" manufactured by Ajinomoto Seiko (Fine Techno Co., Ltd.) corresponding to 1 part by mass of the polyamideimide resin component as a titanium coupling agent, and "Plenact KR41B" as a polyisocyanate The unstabilized polyamide obtained by reacting trimethylolpropane and diphenylmethyl diisocyanate in a polar solvent with respect to 50 parts by mass of the polyamideimide resin component in a molar ratio of 1:3 An isocyanate compound (Coroneto 2503, manufactured by Nippon Polyurethane Industry Co., Ltd.) was used to obtain a paint.

[0070] Next, this paint was applied and fired on the previously shown base to obtain an insulated wire.

Embodiment 2

[0072] Insulated wires were obtained in the same formulation as in Example 1 except that 10 parts by mass of a titanium coupling agent, 200 parts by mass of an unstabilized polyisocyanate compound, and 10 parts by mass of a lubricant were added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| resonance frequency | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com