Rubber composition and use thereof

A technology of rubber composition and copolymer, applied in the direction of reducing the influence of physical parameters, reducing the physical parameters of the carrier, and the manufacture of final products, etc., can solve the problems of insufficient heat resistance, etc., and achieve excellent acid resistance, sealing and insertion. Excellent performance and small compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

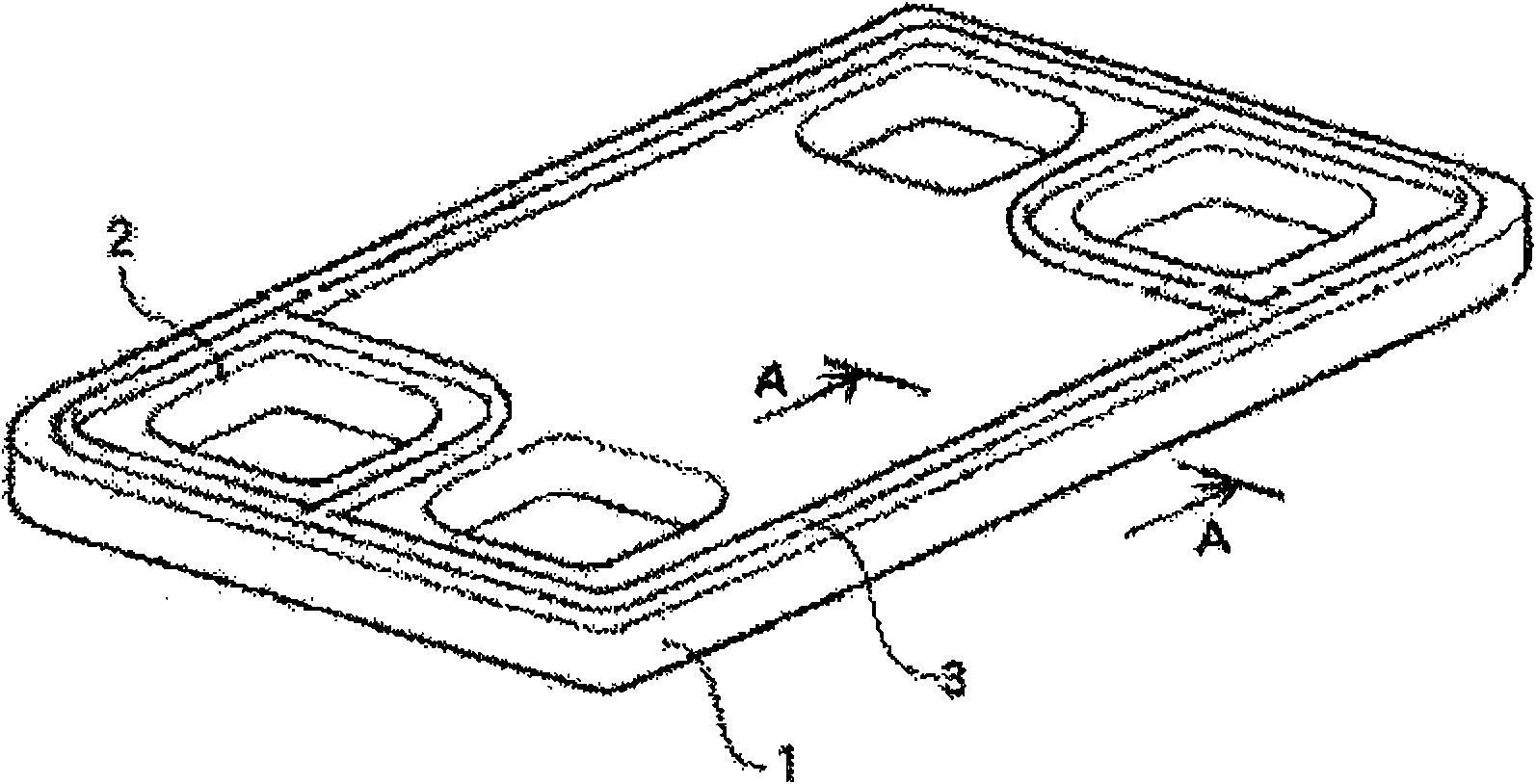

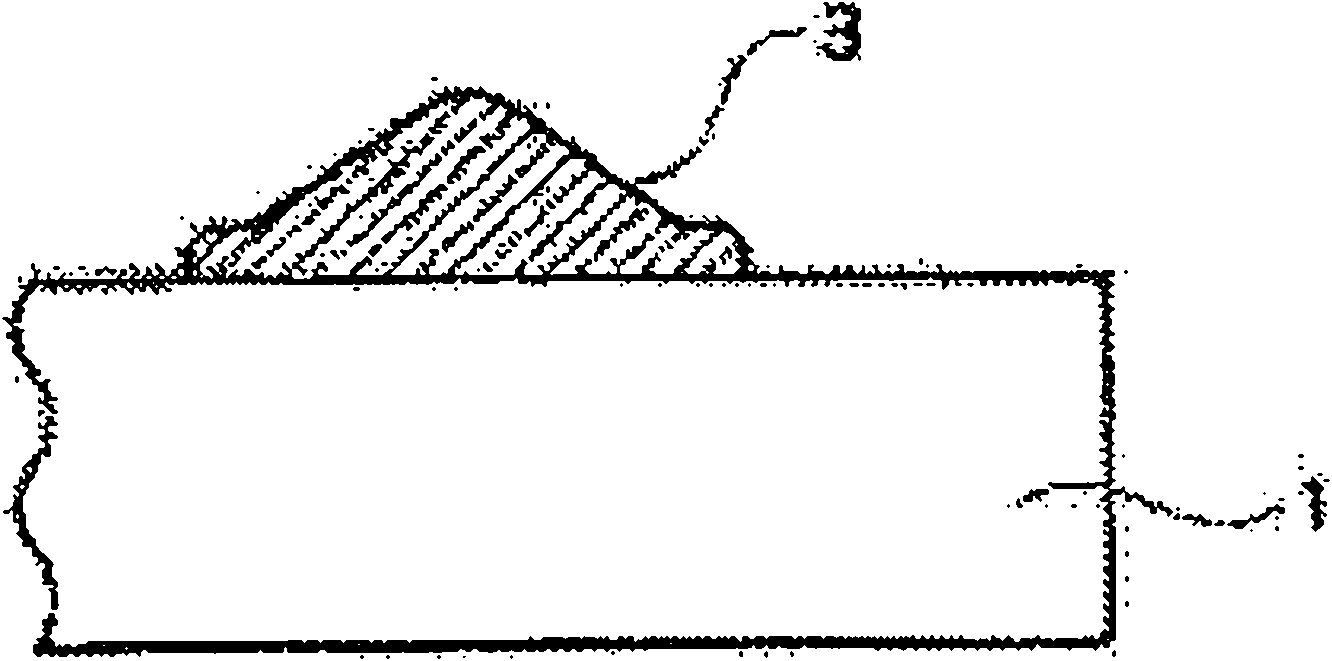

Image

Examples

manufacture example 1

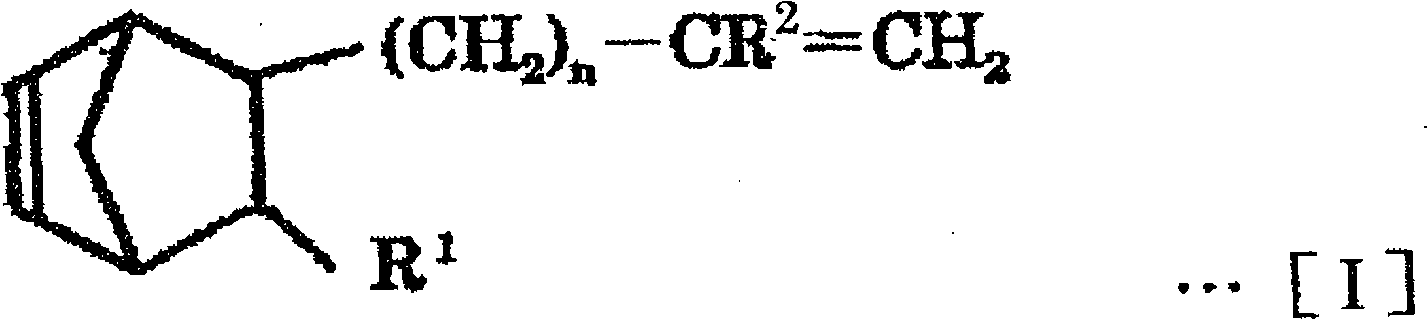

[0214] Production of ethylene-propylene-5-vinyl-2-norbornene random copolymer (A-1)

[0215] Using a stainless steel polymerizer (stirring speed = 250 rpm) equipped with a stirring blade with an actual internal volume of 100 liters, ethylene, propylene, and 5-vinyl-2-norbornene (hereinafter, abbreviated as VNB) were continuously subjected to three-way polymerization. copolymerization. From the side of the polymerizer, at a rate of 60 liters of hexane per hour, 1.3 kg of ethylene, 2.5 kg of propylene, and 130 g of VNB, and at a rate of 30 liters of hydrogen per hour, VO(OEt)Cl as a catalyst 2 23 mmol, Al(Et) 1.5 Cl 1.5 The rate of 161 millimoles was continuously supplied to the liquid phase, and copolymerization was carried out at a polymerization temperature of 40°C and a polymerization pressure of 0.7 MPa to obtain an ethylene-propylene-VNB random copolymer (A-1) in the state of a homogeneous solution (hereinafter, Abbreviated as copolymer (A-1)). Then, a small amount o...

Embodiment 1

[0218]100 parts by weight of the copolymer (A-1) obtained in Production Example 1, 15 parts by weight of calcined talc (manufactured by Asada Flour Milling Co., Ltd., trade name: Enstac 24, average particle diameter 7 μm), and precipitation method 2 after surface treatment Silicon oxide (SS-95 manufactured by Tosoh Silica Co., Ltd., BET surface area: 50m 2 / g, secondary particle size (average particle size obtained by Coulter counting method): 2.4 μm, M value: 65) 30 parts by weight, using a planetary mixer with a capacity of 2 liters [manufactured by Inoue Seisakusho] , trade name: PLM-2 type] kneading in the range of 50 ~ 80 ℃, then add and mix platinum-1,3,5,7-tetravinylmethylcyclosiloxane coordination compound [platinum Concentration 0.5% by weight, terminal vinyl siloxane oil solution] 0.4 parts by weight, 0.1 parts by weight of 1-ethynyl-1-cyclohexanol as a reaction inhibitor, 0.1 parts by weight of the following formula [II-1] as a crosslinking agent A rubber compositi...

Embodiment 2

[0233] In Example 1, instead of surface-treated precipitated silica, carbon black (Asahi #50HG manufactured by Asahi Carbon Co., Ltd., iodine adsorption amount: 19 mg / g, average particle diameter 85 nm, DBP absorption amount: 110 cm 3 / 100g) except that 30 parts by weight were carried out in the same manner as in Example 1 to produce a crosslinked rubber sheet and evaluate properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com