Cold press connector lug device for high voltage

A technology of cold-pressed joints and lugs, applied in the direction of permanent deformation, clamping/spring connection, etc., can solve the problems of accident hazards, falling inside high-voltage electrical appliances, etc., to reduce partial discharge and eliminate hidden dangers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

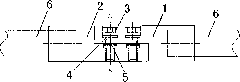

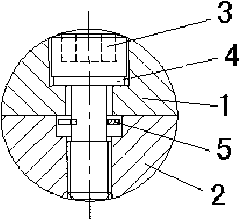

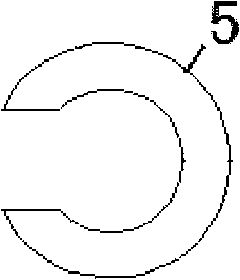

[0013] Such as figure 1 , figure 2 , image 3 As shown, put the hexagon bolt 3 and the butterfly spring washer 4 into the through hole of the male ferrule 1, and then snap the stop washer 5 into the polished rod part of the hexagon bolt 3. In this way, the cold-pressed joint with bolts is assembled; then the two cables 6 are respectively connected to the terminal of the male cold-pressed terminal 1 and the terminal of the female cold-pressed terminal 2 in a cold-pressed manner. Finally, connect the male cold-pressed terminal 1 and the female cold-pressed terminal 2 firmly with bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com