Intermediate piece for the connection of a storage container to a static mixer

A technology of static mixers and middleware, applied in the direction of fluid mixers, containers, mixers, etc., which can solve the problems of difficult injection molding process to manufacture components, complex tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

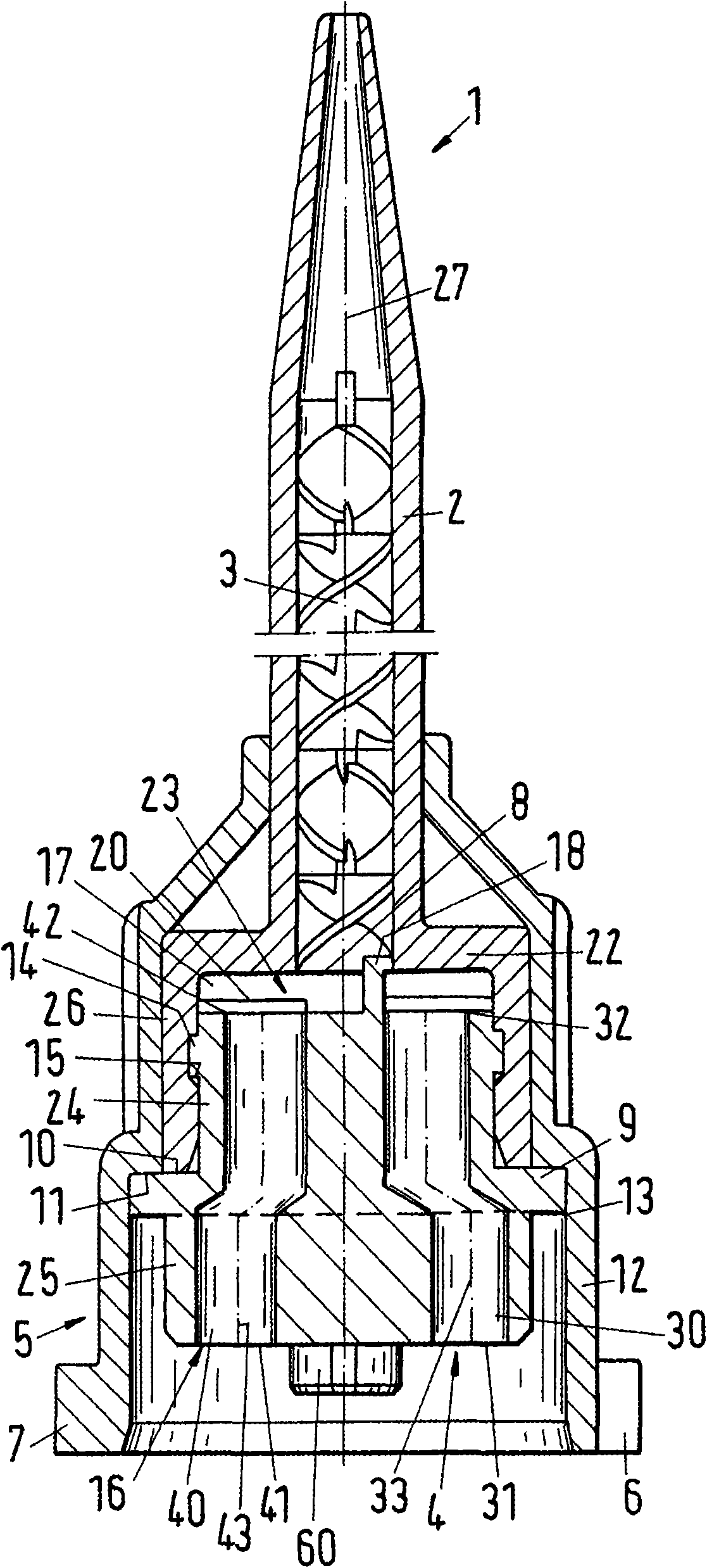

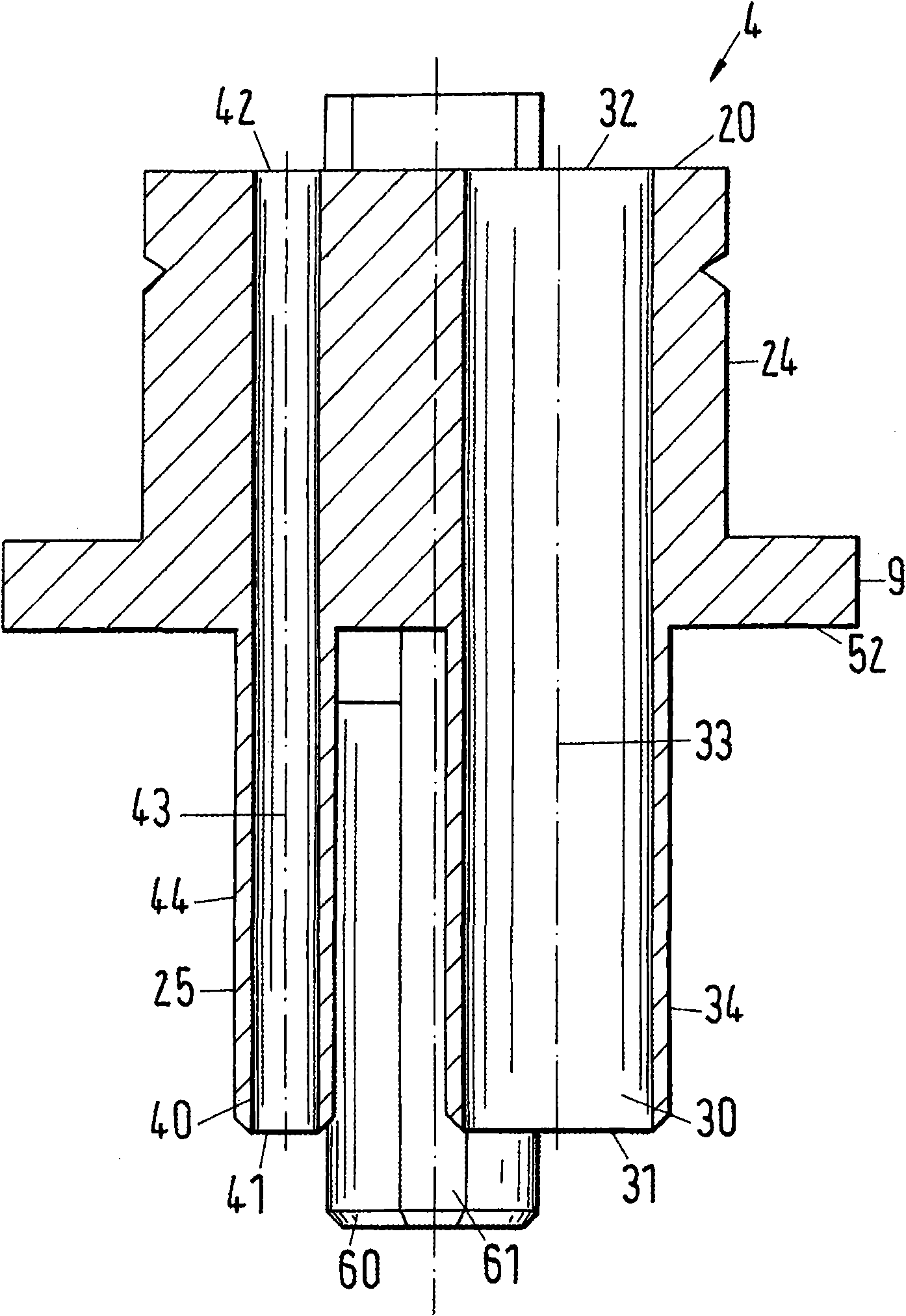

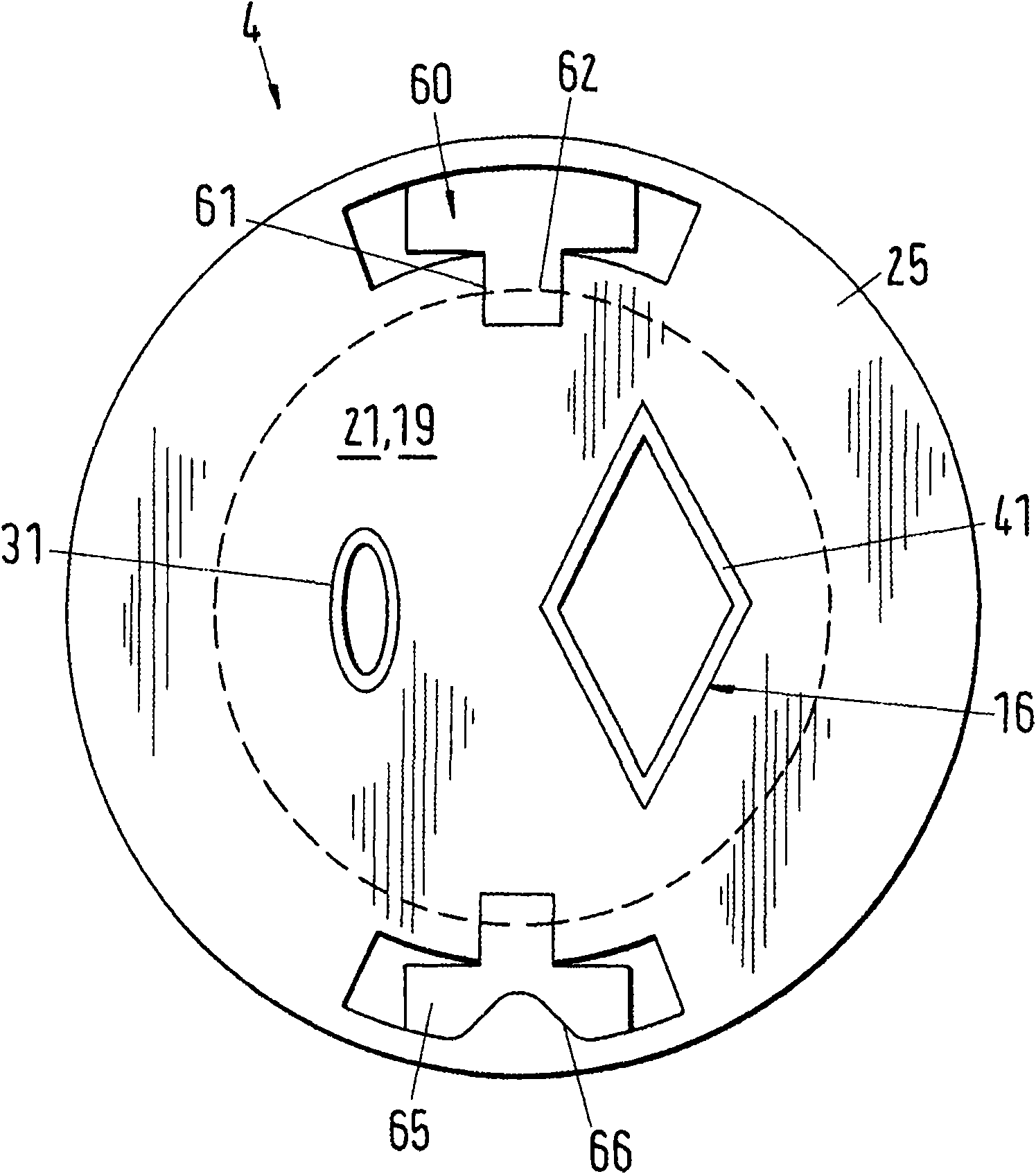

[0042] figure 1 A section through a static mixer 1 with an intermediate part 4 according to a first embodiment of the invention is shown. This static mixer 1 for dispensing cartridges or dispensing devices for multiple components comprises a mixer housing 2 which accommodates at least one static mixing element 3 and can in particular consist of a plurality of mixing elements so that many similar mixing elements are preferably to form a set of mixing elements. Such mixing elements are known, for example, from EP 749776B or EP 1426099B1 or are produced as typified by helical mixers with a helical structure. The mixer has the function of agitating the ingredients sufficiently to form a substantially homogeneous mixture. figure 1 The mixer shown can be used to mix two or more ingredients in the same way. These ingredients may be in a mixing ratio other than the 1:1 mixing ratio. Through the ring coupling element 5 will follow the figure 1 The static mixer is fixed to a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com