Self-displacement universal adjustable pile driving frame and use method thereof

A piling frame and self-changing technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of difficult assembly and disassembly of poles, inconvenient use, increased labor intensity of assembly and disassembly, and prolongation of assembly and disassembly time. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

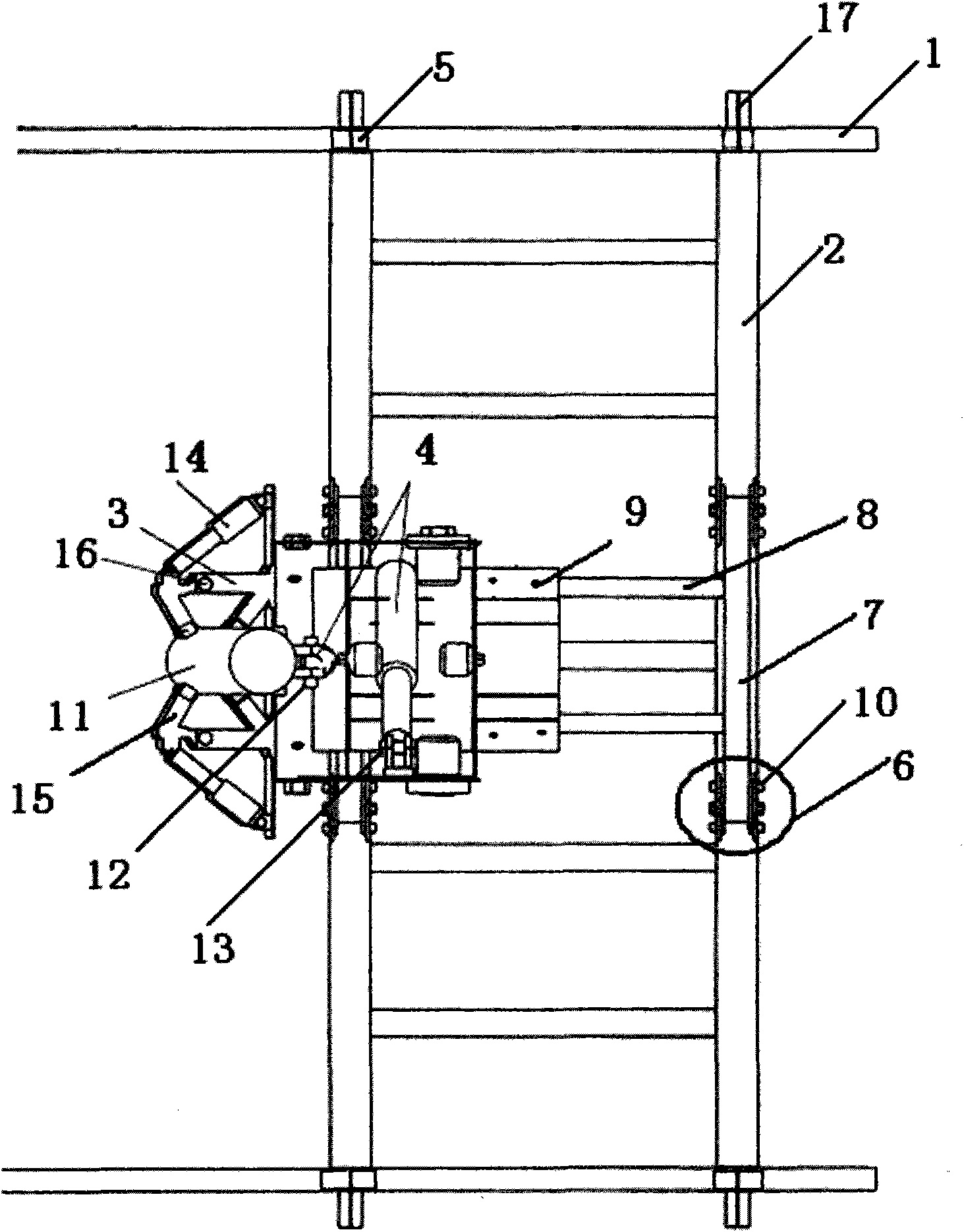

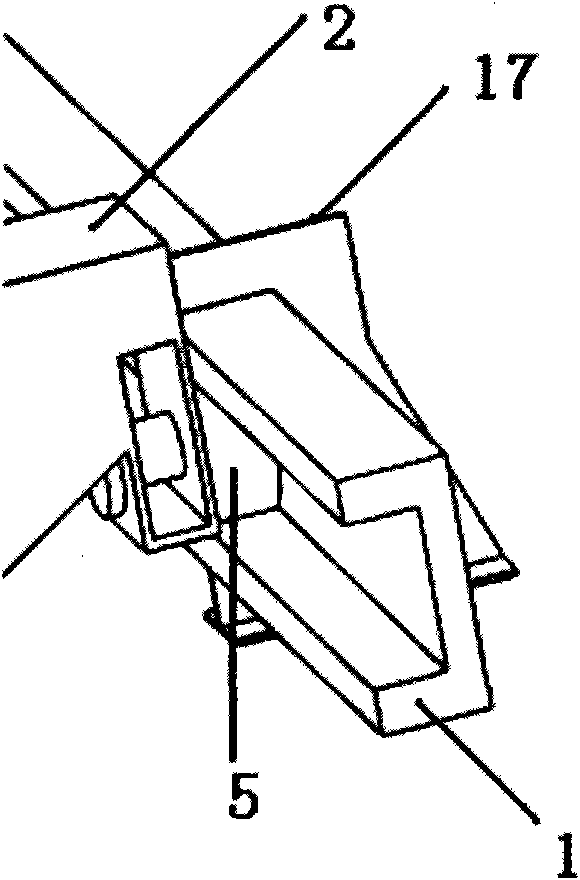

[0015] Such as figure 1 , figure 2 As shown, the present invention is mainly composed of a longitudinal guide rail 1, a transverse guide rail 2, a fully automatic hydraulic engagement device 3 and a guide oil cylinder 4, the longitudinal guide rail 1 and the transverse guide rail 2 are combined through reinforcing ribs 17, and the wheels 5 combined with the transverse guide rail 2 It is located on the concave-shaped guide rail of the longitudinal guide rail 1 and can move longitudinally along the guide rail.

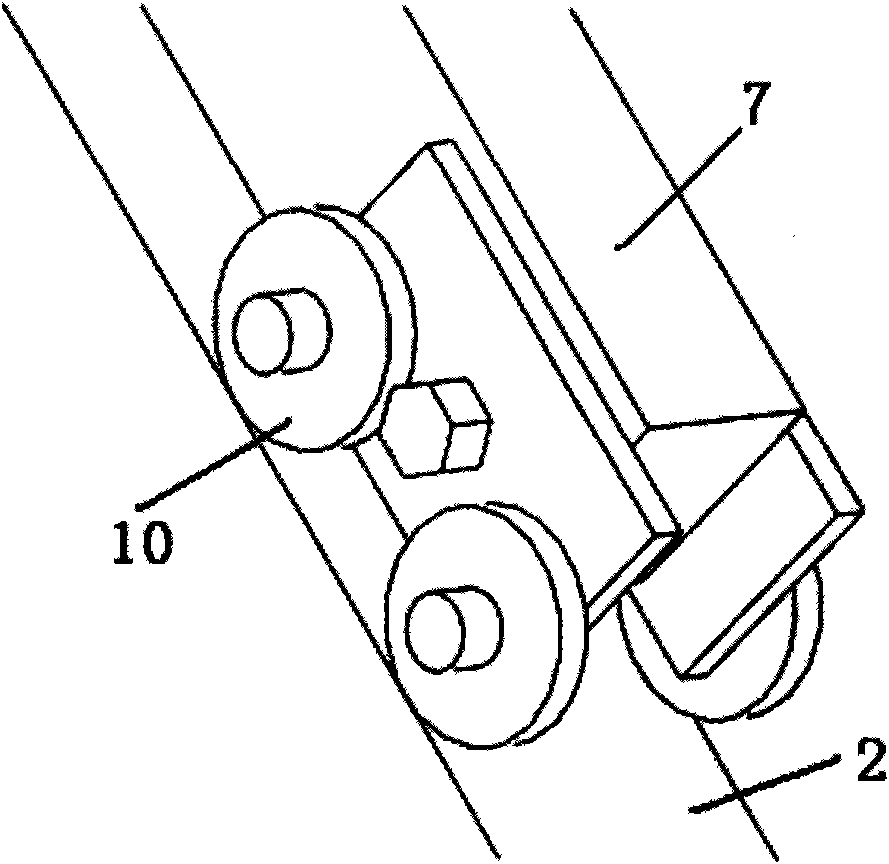

[0016] Such as figure 1 , image 3 As shown, two guide cars 6 are respectively arranged on two parallel transverse guide rails 2, and the two guide cars 6 on the same guide rail are connected by a transverse connecting plate 7, and the two transverse connecting plates 7 parallel to each other pass through each other. The parallel longitudinal connecting plates 8 are connected, so far the longitudinal and transverse connecting plates and the guide car are connected as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com