Backheating type absorption-generation system and backheating type first class absorption heat pump

A technology of absorption heat pump and generation system, which is applied in the direction of adsorption machines, energy-saving heating/cooling, lighting and heating equipment, etc., and can solve problems such as performance index differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0129] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

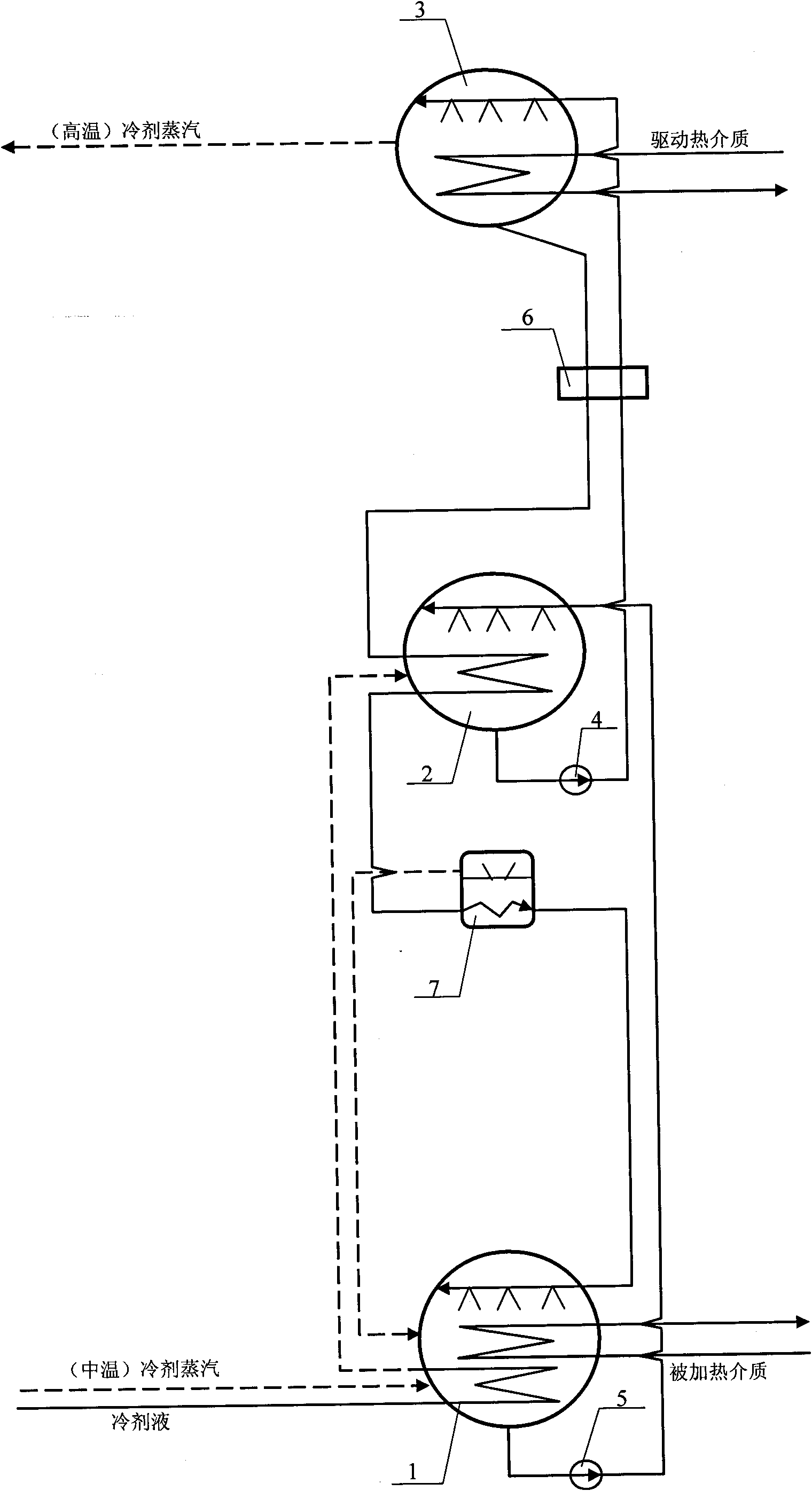

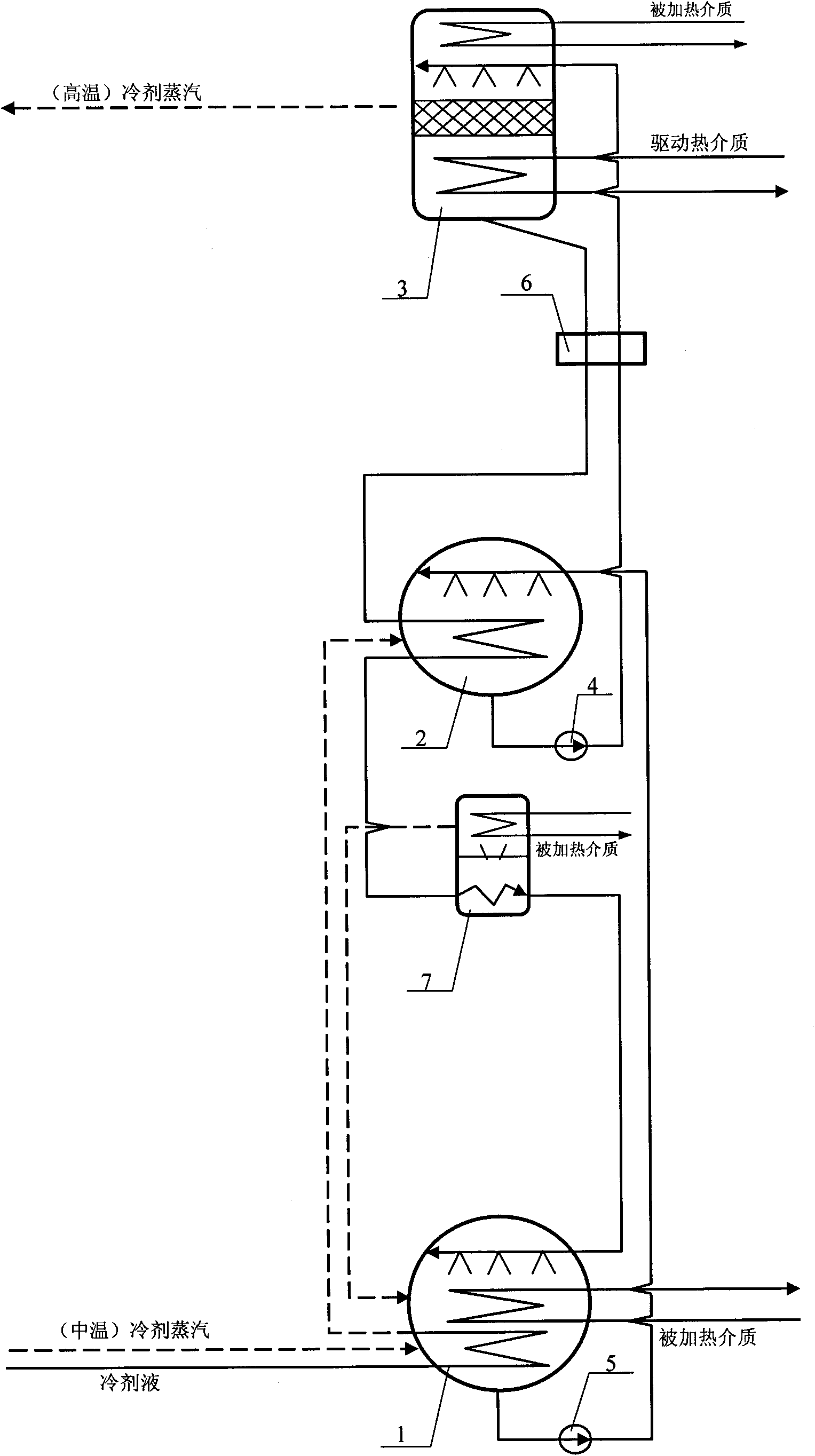

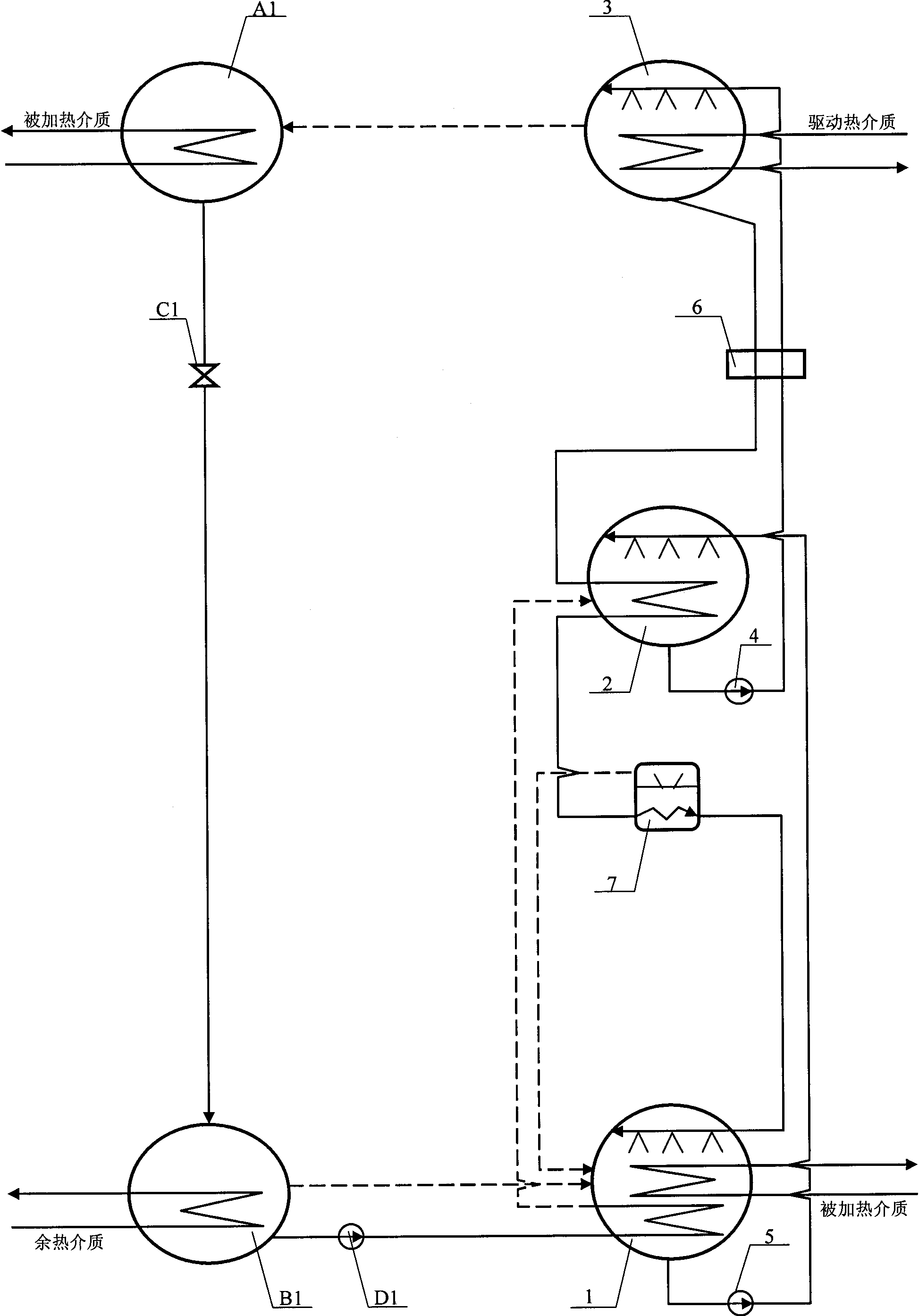

[0130] figure 1 The regenerative absorption-generation system shown is implemented as follows:

[0131] ① Structurally, it is mainly composed of the first absorber, the second absorber, the generator, the first solution pump, the second solution pump, the solution heat exchanger and the steam distribution chamber; the first absorber 1 has a dilute solution pipeline The second absorber 2 is communicated with the second absorber 2 through the second solution pump 5, and the second absorber 2 and the dilute solution pipeline are communicated with the generator 3 through the first solution pump 4 and the solution heat exchanger 6, and the generator 3 also has a concentrated solution The pipeline communicates with the steam distribution chamber 7 through the solution heat exchanger 6 and the second absorber 2, and the steam distribution chamber 7 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com