Secondary series type permanent-magnet speed governor

A permanent magnet speed governor, series-type technology, applied in the direction of asynchronous induction clutch/brake, etc., can solve the problems of inconvenient adjustment, large space occupation, and long adjustment distance of the regulator, so as to reduce the occupied space and shorten the adjustment distance , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

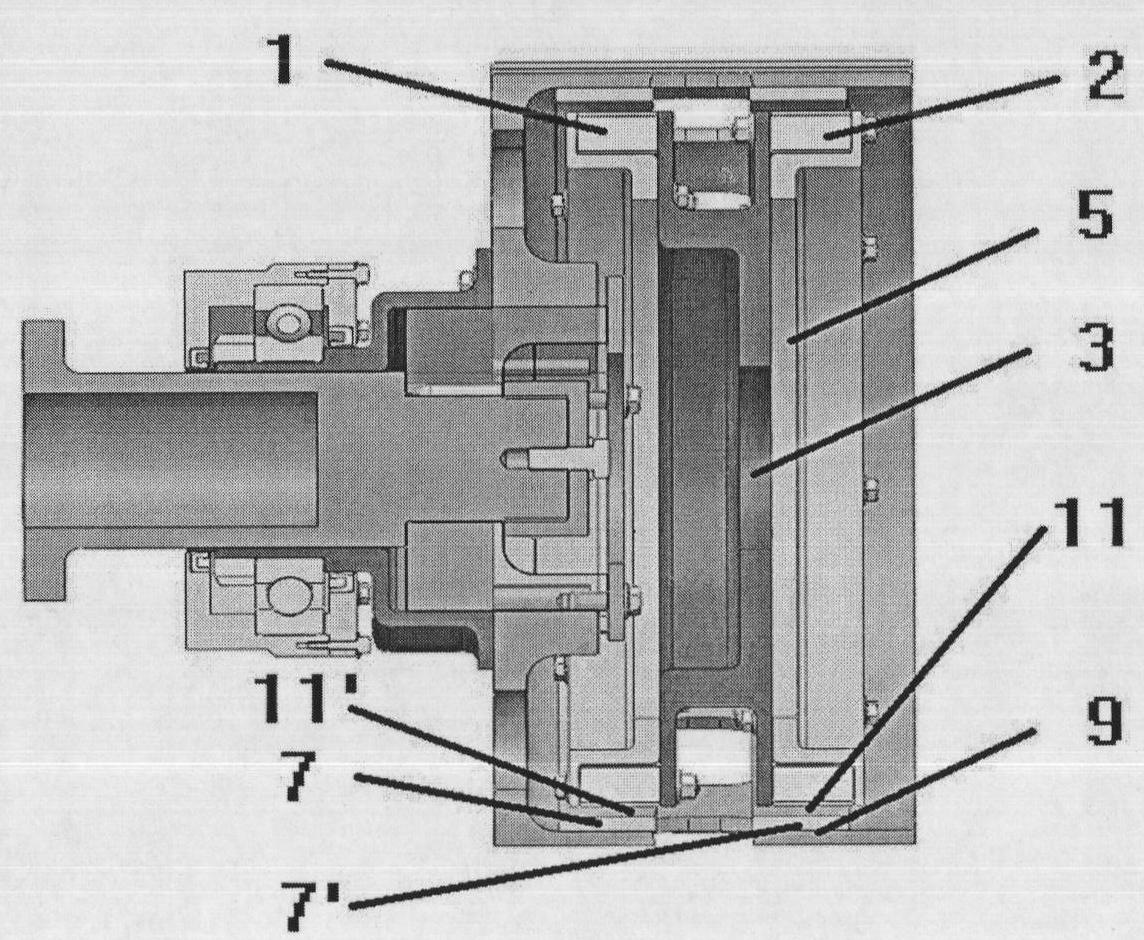

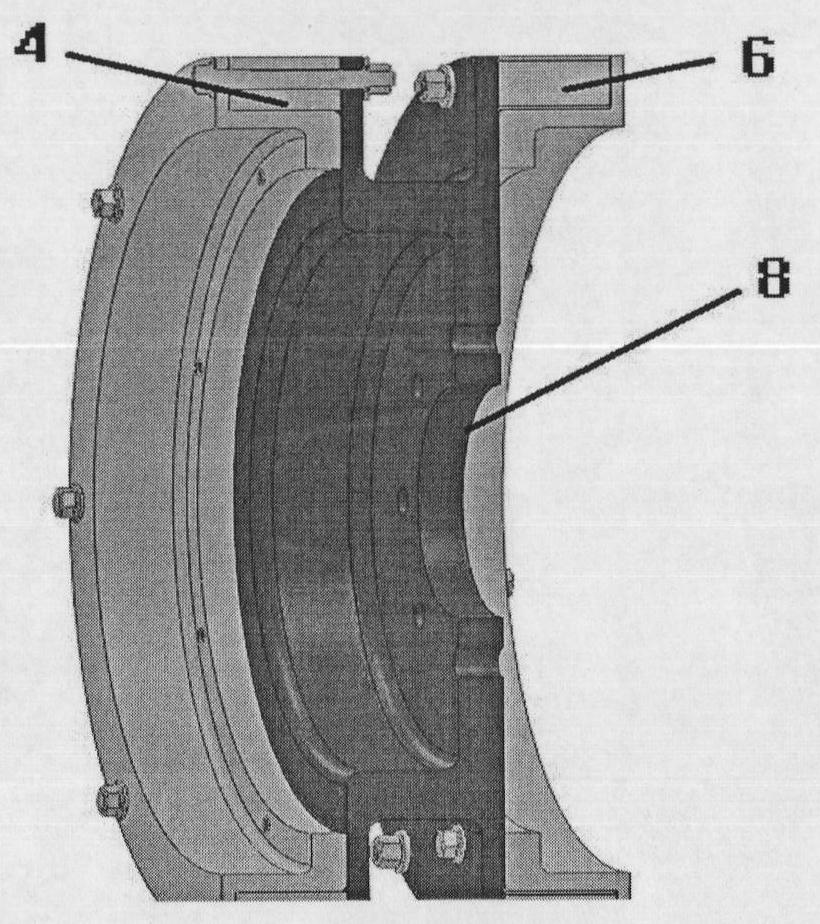

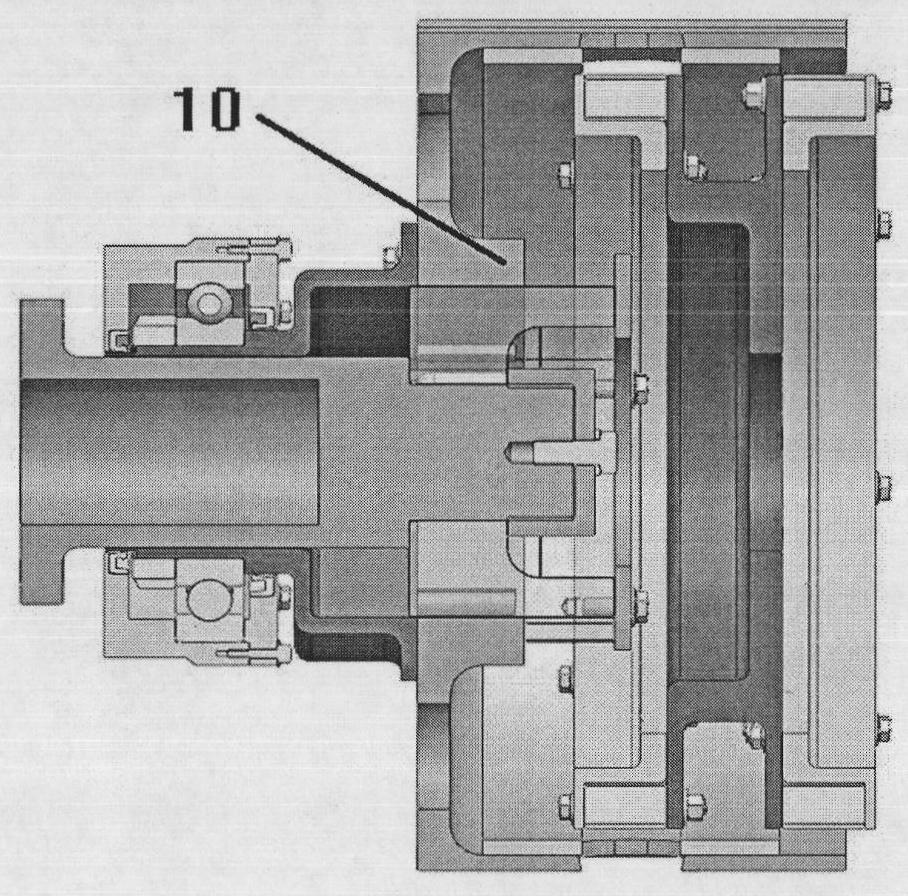

[0016] Reference attached Figure 1~4 :

[0017] The permanent magnet rotor 8 is designed as a two-stage series type, and its structure includes a left magnet rotor 1, a right magnet rotor 2 and a magnet support frame 3. The left magnetic rotor 1 and the right magnetic rotor 2 are respectively mounted on both sides of the magnet support frame 3, and both are composed of a magnetic base 4 with a magnet 6 installed and a stepped baffle 5. The magnetic base 4 has a ring shape, and a magnet 6 is mounted on the outer ring. One end of the stepped baffle 5 is connected with the outer surface of the magnetic base 4 and the other end is connected with the magnet support frame 3. The magnet support frame 3 is a fork-shaped structural component whose outer walls on both sides are respectively connected with the left and right magnetic rotors 1, 2, the middle part is cylindrical, and the bottom of the cylinder is connected with the load shaft.

[0018] The conductor 77' of the cylindrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com